High Accuracy Static Levels to Eliminate Temperature Drift

A static level, temperature drift technology, applied in the direction of hydrostatic pressure and the like, can solve the problems of weakening the influence of temperature drift measurement accuracy, high algorithm complexity, and difficulty in implementation, achieving ingenious structural design and avoiding large-angle offsets. , the effect of increasing the draft cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

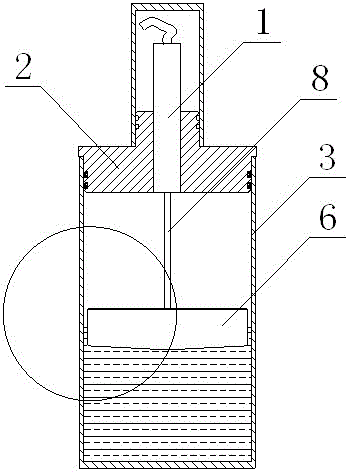

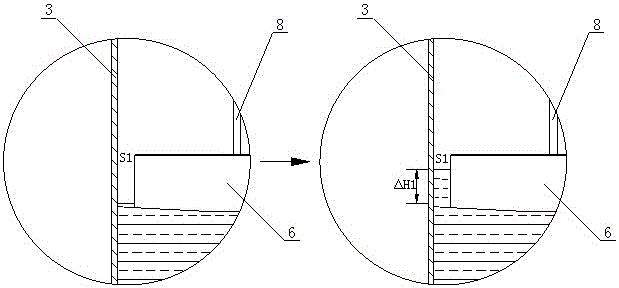

Image

Examples

Embodiment 1

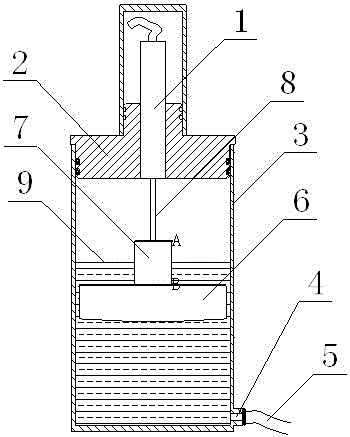

[0033] Embodiment one: if image 3 As shown, the limit assembly 6 is installed below the float 7, below the liquid surface 9, the liquid surface 9 is immersed in the limit assembly 6 and not immersed in the float 7, that is, to ensure that the liquid surface 9 is at the points A and B of the float 7 between.

Embodiment 2

[0034] Embodiment two: if Figure 4 As shown, the limit assembly 6 is installed above the float 7 and above the liquid level 9 to ensure that the liquid level 9 is between points A and B of the float 7 .

Embodiment 3

[0035] Embodiment three: as Figure 5 As shown, the limit assembly 6 is installed on the float 7 through the connecting piece b10 to ensure that the liquid level 9 is between the points A and B of the float 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com