Occlusion depth gauge

A measuring tool and in-depth technology, applied in the field of measuring tools, can solve the problems of increasing labor intensity, low efficiency, cumbersome steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

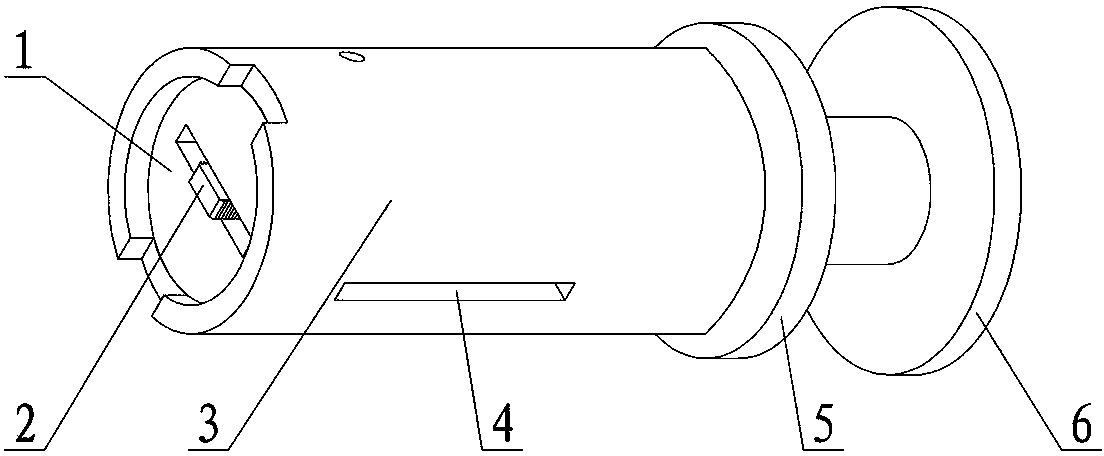

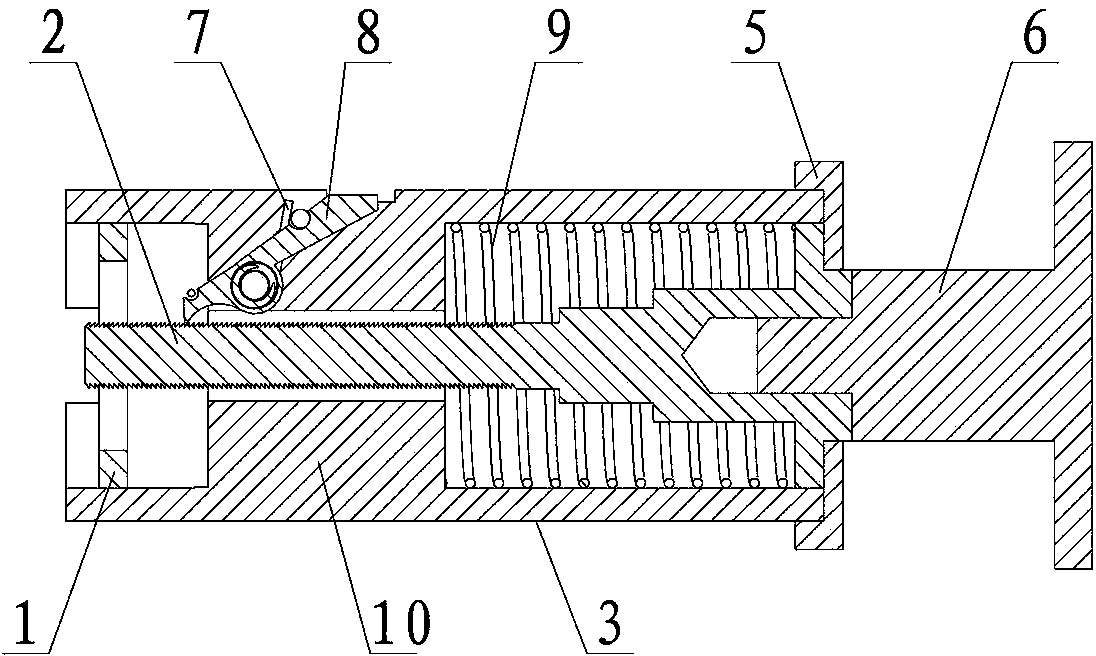

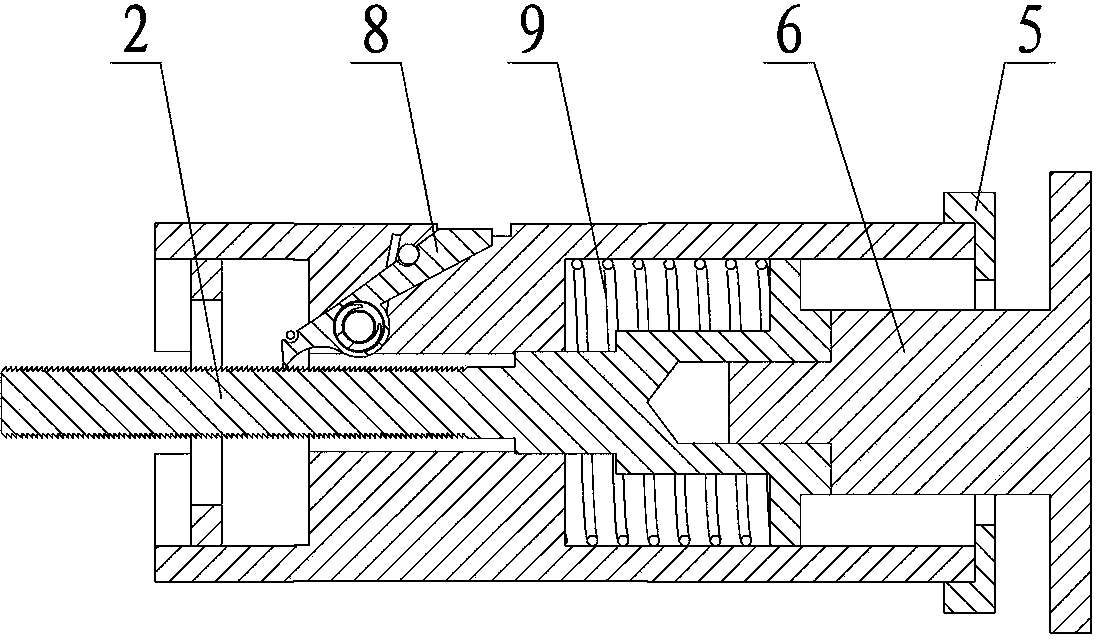

[0017] The embodiment of occlusal depth gauge of the present invention: as Figure 1-5 As shown, it includes a positioning cylinder 3 and a measuring stick 2. The positioning cylinder 3 is a cylindrical structure adapted to be inserted into the contact arm 11. Its right end is detachably fixed with an annular end cover 5. The measuring stick 2 is rotated from right to left. Inserted in the positioning cylinder 3, its left section is a scale section 21, and the front and rear side walls of the scale section 21 are marked with size scales. The outer edge of the end cap 5 protrudes from the outer peripheral surface of the positioning cylinder 3, so that when the positioning cylinder 3 is fitted and inserted in the contact arm 11, the end cap 5 is located in the plum blossom contact 12, and its protruding part plays a role of limiting to the left. At the same time, the left end surface of the protruding part of the outer edge of the end cover is the positioning datum plane; the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com