Lifting mechanism

A lifting mechanism and sliding block technology, applied in the field of lifting mechanism, can solve the problems of limited space, high cost, high price, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

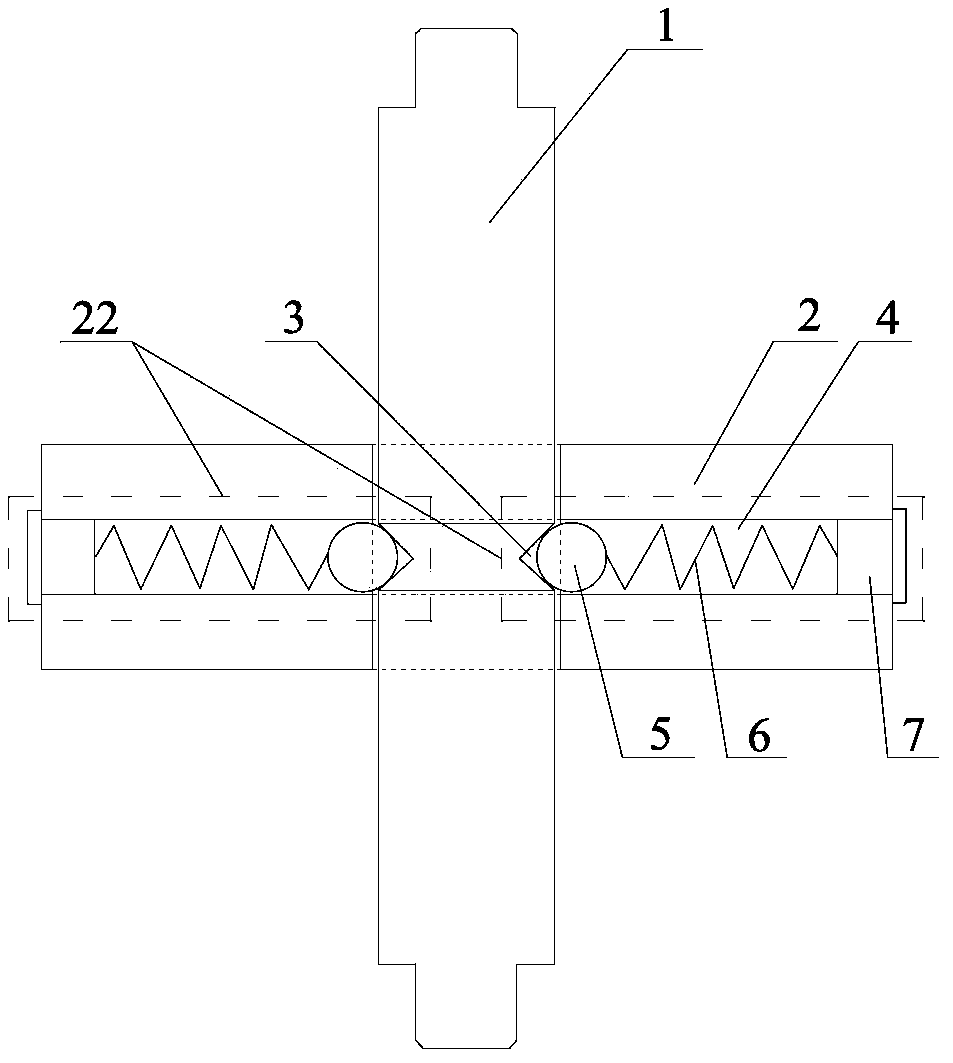

[0009] See attached figure 1 The lifting mechanism provided by the present invention includes a limit shaft 1, a slider 2 and at least two sets of positioning components 22. The slider 2 is sleeved on the limit shaft 1, and the positioning component 22 is arranged on the slider 2. There are multiple positioning intervals 3 in the vertical direction (only one positioning interval is drawn in this embodiment, in practice, multiple positioning intervals can be provided along the axial direction of the limit shaft 1), and the positioning assembly 22 can be snapped on The positioning section 3 enables the position of the slider 2 to be fixed after the lifting.

[0010] Wherein, as a specific implementation of the positioning section 3, the positioning section 3 can be a conical notch indented t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com