Shielding device for automatically checking pressure resistance and leakage safety of poisoning cabin

An automatic inspection and shielding device technology, applied in the direction of detecting the presence of fluid at the leak point, measuring devices, testing of machine/structural components, etc., can solve problems such as inspection of no gas leakage, cabin rupture, cabin leakage, etc. , to achieve the effect of solving the automatic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

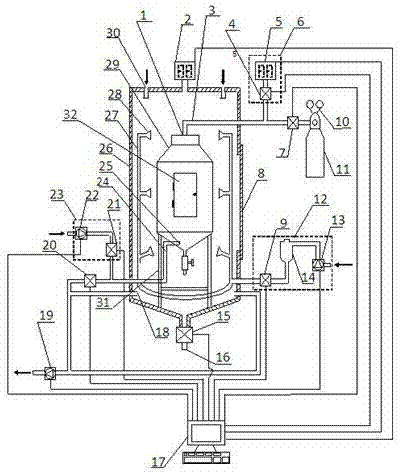

[0017]When using the shielding device that automatically checks the pressure resistance and leakage safety of the poisoned cabin body, at first prepare experimental animals and experimental equipment and articles, fill up the soap liquid tank 12 with soap that can foam, and close the middle side of the shielded cabin body 26 Shield door 8 on the position and the sealing switch cabin door 32 of poison cabin body 29 fronts; Connect the power supply of computer controller 17, close poison valve 7, liquid inlet valve 9, water discharge valve 15 with computer controller 17 control And detoxification valve 20, computer controller 17 controls and starts negative pressure blower 19, and negative pressure blower 19 is directly connected with the negative pressure suction port 18 of shielding cabin body 26 by sealed pipeline, and the suction of negative pressure blower 19 makes shielding cabinet 26 Negative pressure is generated inside, so that the outside world is isolated from the shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com