a seal lock

A technology of imprinting and locking shell, applied in the field of anti-theft locks, can solve the problems of preventing the desire to buy and the cost of construction, and achieve the effects of low cost, simple production process, and strong anti-technical opening ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

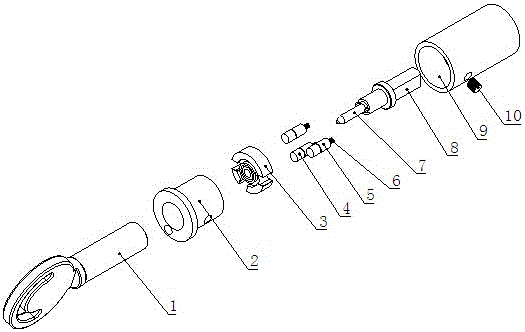

[0030] Embodiment 1: with reference to attached Figure 1-5. An imprint lock, characterized in that it includes a lock case 9, a lock case cover 2, a dial 3, a bolt post 8, an upper lock bead 4, a lower lock bead 5, a compression spring 6, a key 1, and one end of the lock case 9 is provided with a There is a large groove, the lock case cover 2 is packed into the lock case 9 large grooves, the lock case cover 2 and the lock case 9 are fixed with the fixing pin 10, and the dial 3 is placed in the space formed between the lock case cover 2 and the lock case 9 Cavity, number plate 3 two end surfaces are respectively against the bottom surface of lock housing cover 2 and lock housing 9 large grooves; the center of lock housing 9 large grooves has a middle groove, and the center of the middle groove has a through hole, and the lock housing 9 is equipped with Bolt column 8, the bolt column 8 is against the bottom surface of the middle groove, the rotating shaft end of the bolt colum...

Embodiment 2

[0036] Embodiment 2: with reference to attached Figure 6 . An imprint lock, characterized in that it includes a key 1, a lock case cover 2, a dial 3, an upper lock bead 4, a lower lock bead 5, a magnetic bead, a bolt post 8, a lock case 9, and a large groove in the lock case 9 There are 3 small grooves arranged around the bottom surface and the middle groove, and each small groove is equipped with a magnetic bead and a lower lock bead 5. The magnetic bead and the lower lock bead 5 are permanent magnet materials. Repulsive force, the magnetic beads are against the bottom of the small groove. Three through holes are provided on the 3 end faces of the dial, and the positions and numbers of the through holes are

[0037] The amount corresponds to the position and quantity of the lower locking beads 5, and an upper locking bead 4 is placed in each through hole, and the height of the upper locking beads 4 is smaller than the thickness of the dial 3; Enter the through hole of the...

Embodiment 3

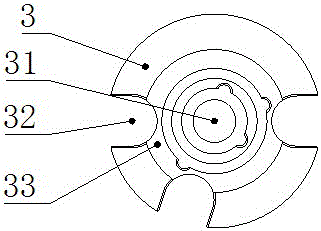

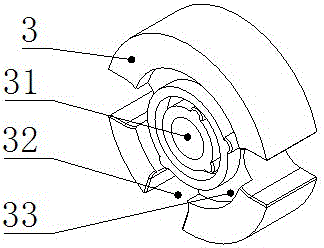

[0038] Embodiment 3: with reference to attached Figure 7 . An imprint lock, which is characterized in that it includes a key 1, a lock case cover 2, a dial 3, an upper lock bead 4, a lower lock bead 5, a compression spring 6, a bolt post 8, and a lock case 9, and the dial 3 is provided with a concave The groove can also be called the key groove 33, and the surface of the key groove 33 faces the end surface of the key and is provided with a combination of protrusions and recesses that cooperate with each other. The protruding part on the surface of the dial key groove is in the shape of an apple pattern, and the key is correspondingly provided with a recess for inserting the protruding part on the surface of the dial key groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com