Snow melting agent spreading device

A snow melting agent and hopper technology, which is applied in the field of road pavement maintenance equipment, can solve the problems of road snow and ice, low efficiency, waste of snow melting agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

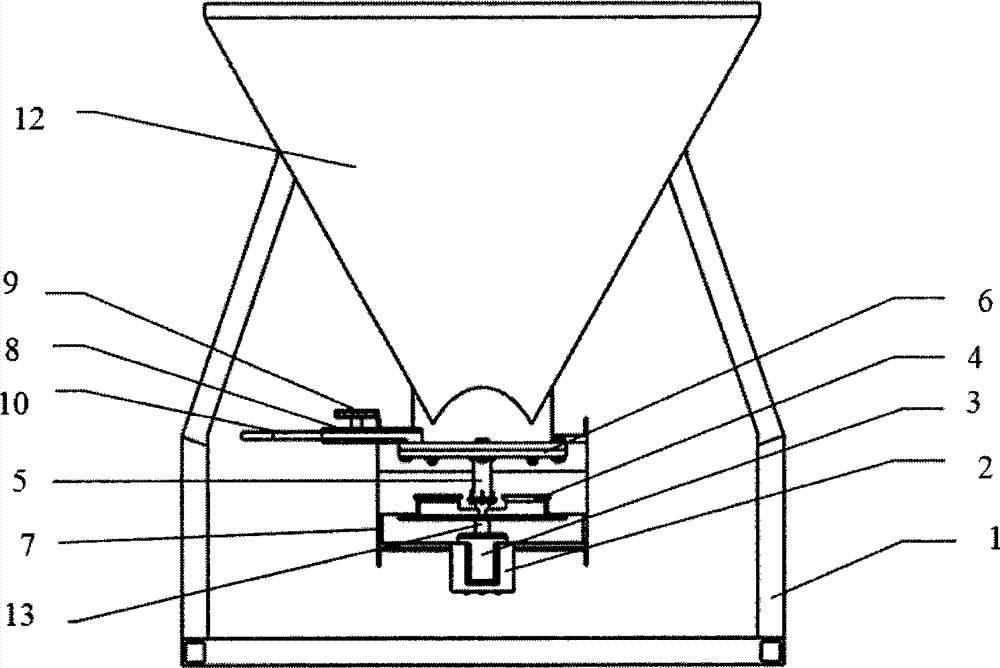

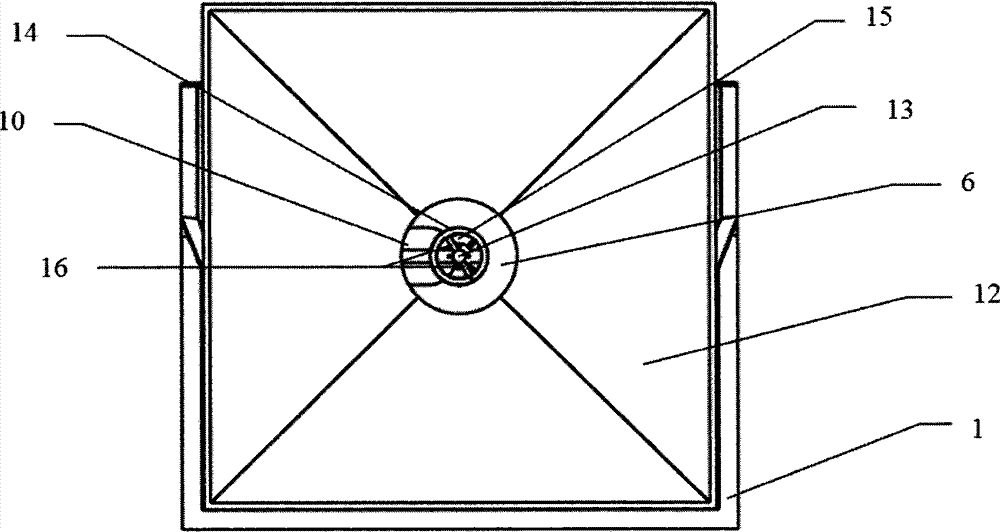

[0016] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] As shown in Figures 1-5, the equipment of the present invention has a total support frame 1, a hopper 12 is installed on the top of the total support frame 1, and a discharge port 15 is arranged below the hopper 12. Below is the motor 3, the motor 3 is fixed on the motor support frame 2 with bolts, the motor support frame 2 is fixed on the hopper 12 with bolts, and the output shaft 13 of the motor is sequentially fixed upwards with a throwing turntable 4 and a coil spring 14, and the coil spring 14 is placed Directly above the discharge port 15, above the throwing turntable 4 is the bearing and the bearing outer cylinder 5, a baffle guide rail 8 is provided on one side of the hopper, the baffle plate 10 is inserted in the baffle guide rail 8, and the upper panel of the baffle guide rail 8 is marked with Positioning hole, the plum blosso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com