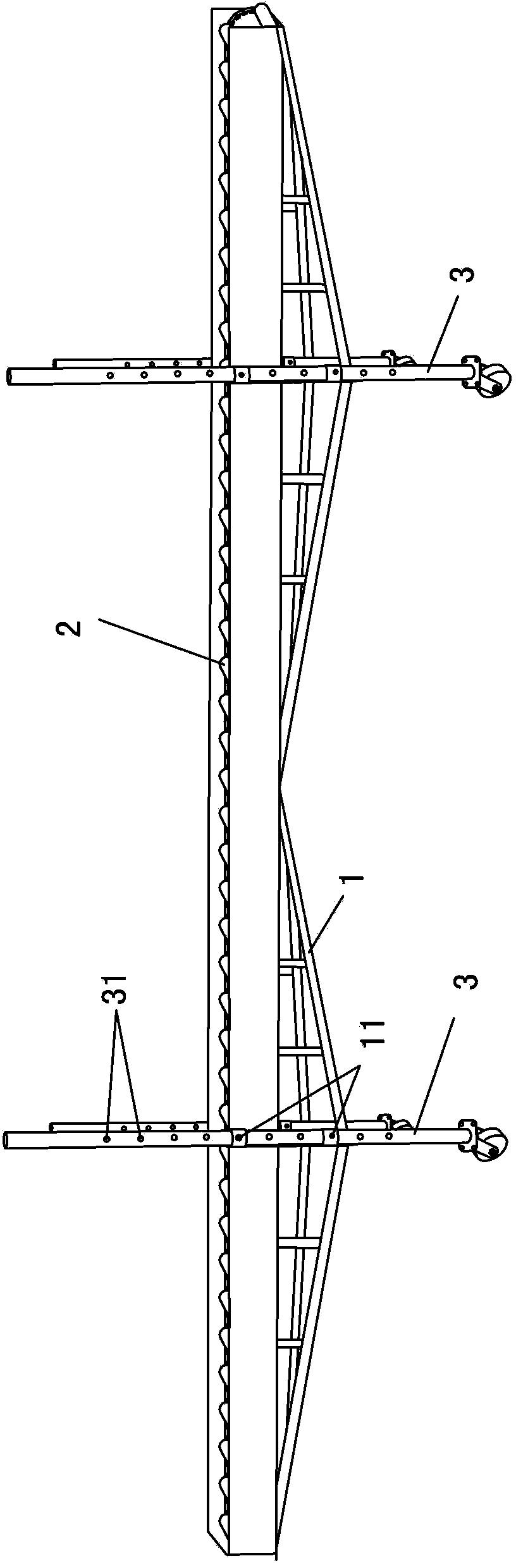

Dual-segment lifting type conveying mechanism

A technology of lifting mechanism and transmission mechanism, which is applied in the direction of transportation, packaging, roller table, etc., can solve the problems of endangering personal safety and property safety, time-consuming and labor-intensive adjustment process, and dangerous transmission track 2, etc., and achieves convenient operation, convenient maintenance, and support The effect of teleportation orbit stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

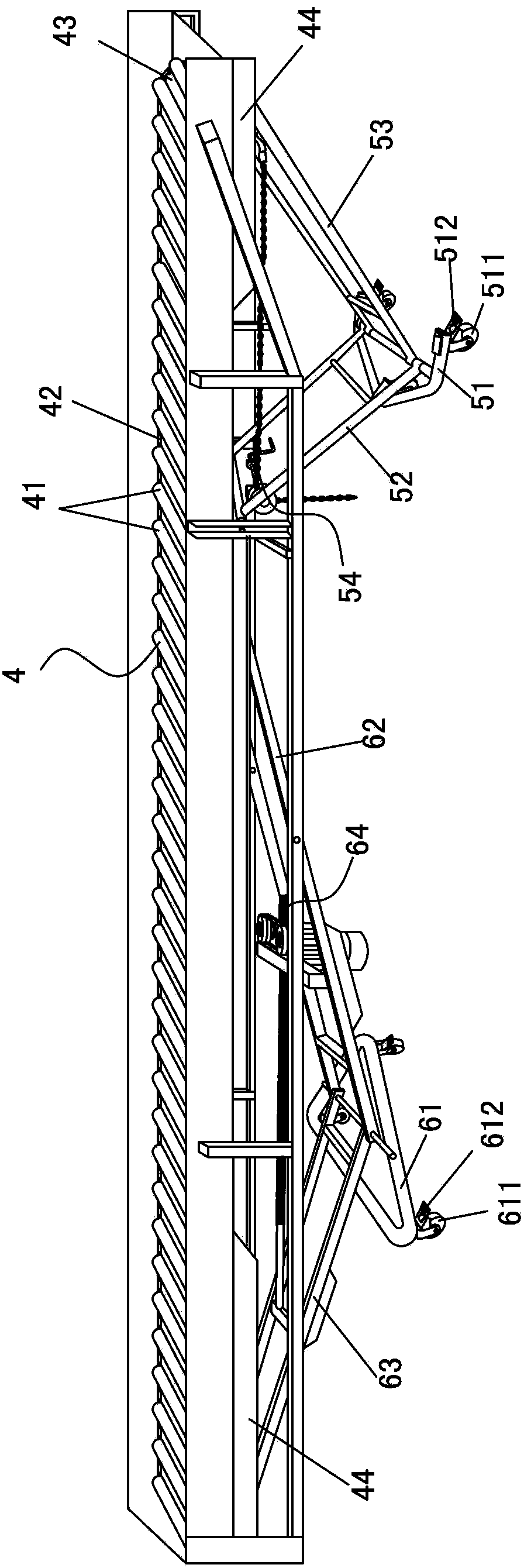

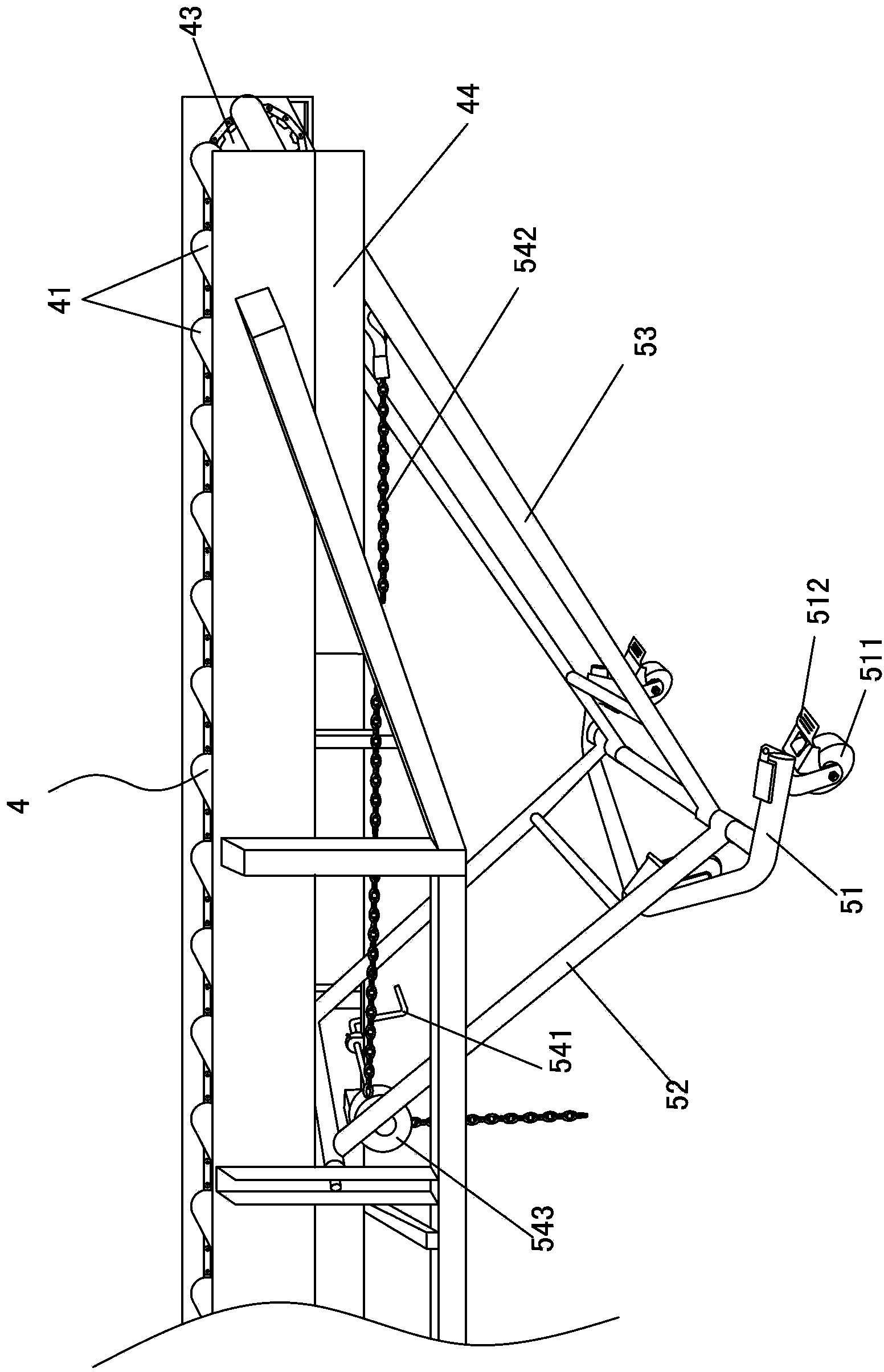

[0025] Examples, see Figure 2 to Figure 5 As shown, a kind of double-stage lifting conveying mechanism of the present invention comprises conveying track 4 and the first lifting mechanism 5 and the second lifting mechanism 6 that are installed below conveying track 4; Said first lifting mechanism 5 comprises a first base 51. Two first legs 52, 53 and a first driving device 54, the second lifting mechanism 6 includes a second base 61, two second legs 62, 63 and a second driving device 64; the first lifting mechanism 5 The bottom ends of the two first legs 52, 53 are respectively hinged on the first base 51, the top of one of the first legs 52 of the first elevating mechanism 5 is hinged on the bottom surface of the conveying track 4, and the other first leg The top of 53 can be horizontally slidably connected to the bottom surface of one end of the transmission track 4, and the first driving device 54 is connected between the tops of the two first legs 52, 53 of the first elev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com