A multifunctional rotary tool assembly

A rotary tool and multi-functional technology, which is applied in the field of multi-functional rotary tool components, can solve the problems of low operation adaptability, large manpower consumption, single repetition, etc., achieve simple locking process, improve utilization rate, and solve synchronization errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiments.

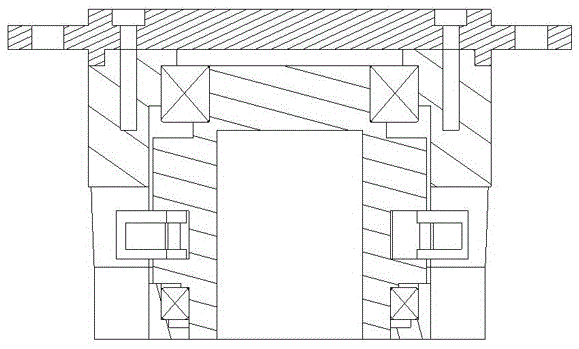

[0028] Such as figure 1 As shown, the present invention mainly includes two parts of a multi-function tool head 1 and a lock head 2, and the lock head 2 is used to be fixed on different rotary tools 3.

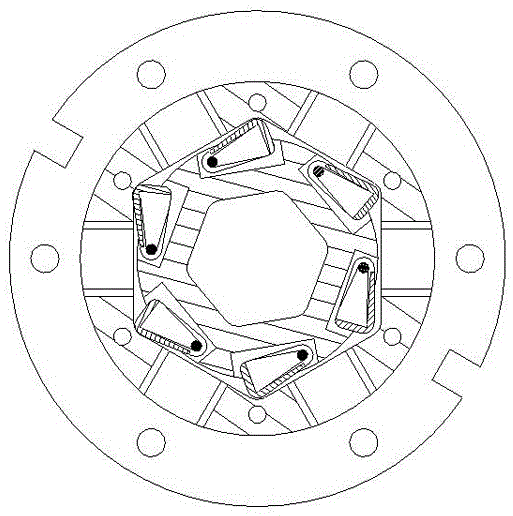

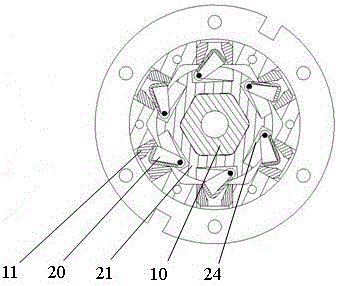

[0029] Such as figure 2 and image 3 As shown, the multifunctional tool head is equipped with a frame 6 on the outside, and the frame 6 is provided with a connection interface with the mechanical arm, and a camera and lighting device 8 is installed according to the demand, and the electrical part of the camera and lighting device 8 is installed in the electrical box 7 on the side of the frame 6 middle. The rear part of the multifunctional tool head is a motor box 5, the middle part is a gear box 4, and the front part is equipped with a lock key 10 along the axis. A number of lock buckles 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com