End-enhanced steel-reinforced concrete superposed beam

A technology of end reinforcement and concrete, applied in the direction of joists, girders, truss beams, etc., can solve the problems of poor torsional performance, durability and fire resistance, large demand for shaped steel reinforcements, and high construction costs, so as to improve the bearing capacity capacity, reduce production costs, and avoid waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now further illustrate the implementation process of the present invention in conjunction with accompanying drawing.

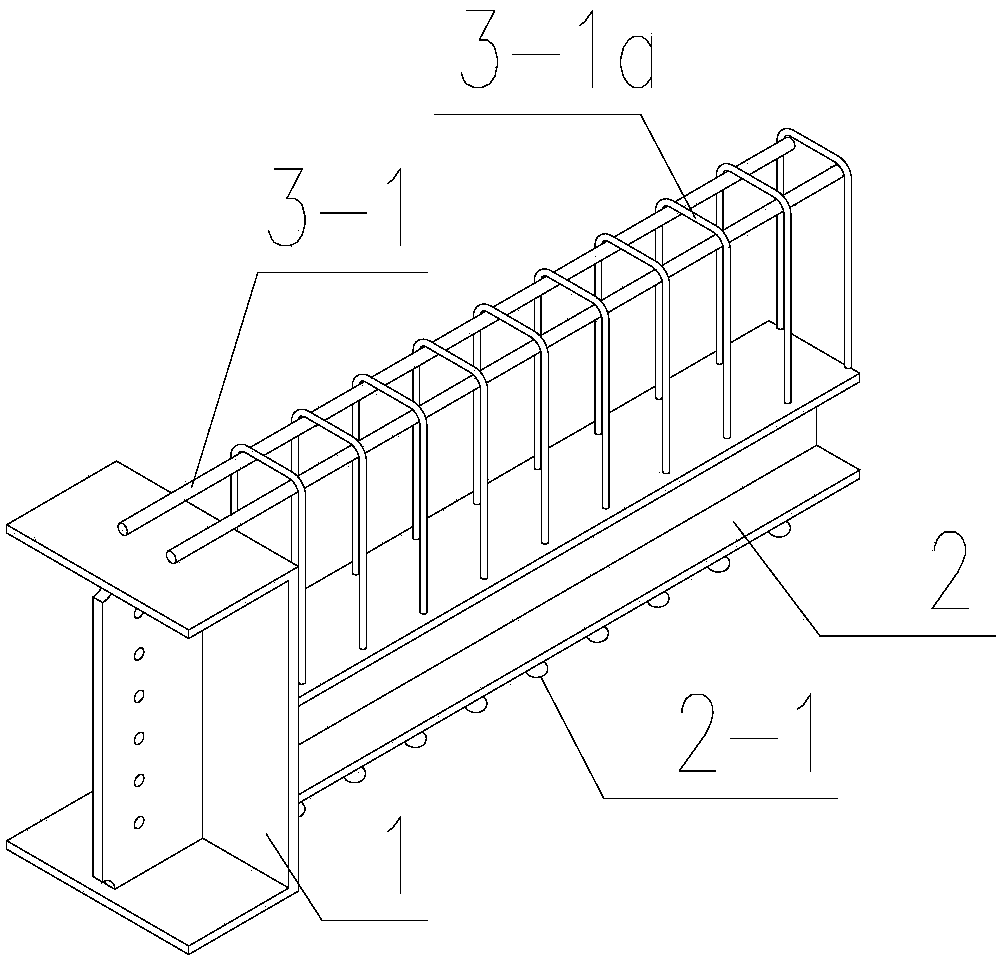

[0018] The present invention is an end-reinforced steel-reinforced concrete composite beam, which is composed of a prefabricated steel frame, a prefabricated concrete steel frame lower beam and a cast-in-place concrete steel frame upper beam. The H-shaped steel 2 is composed of steel bars and reinforcement cage system 3. The end-shaped steel connectors 1 are respectively connected to the outer ends of the two ends of the H-shaped steel 2, and the longitudinal overhanging steel bars 3-1 are welded on the top of the shaped steel connectors 1 through the end. The П-shaped steel bar 3-1a welded at intervals on the upper flange of H-shaped steel 2 is hooped to form the steel cage at the end of the shaped steel frame; The upper and lower sides of the plate are symmetrically connected to the full-length longitudinal reinforcement 3-2 of the beam body, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com