Automatic assembly device for watch winding stem assembly

An automatic assembly and arbor technology, applied in workpiece clamping devices, metal processing equipment, clocks and other directions, can solve the problems of high defective rate, easy to break or bending arbor, lack of protection of arbor and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

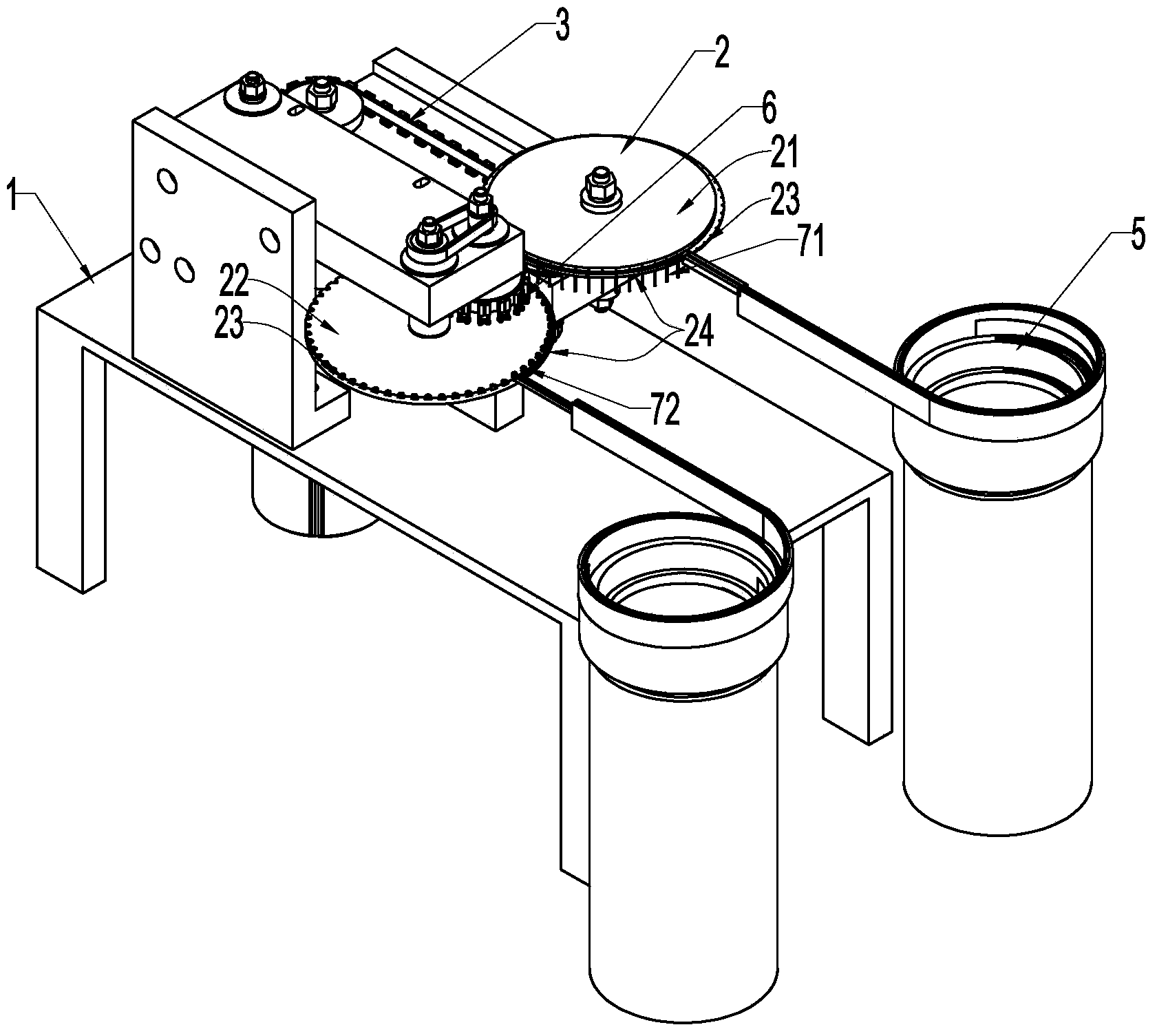

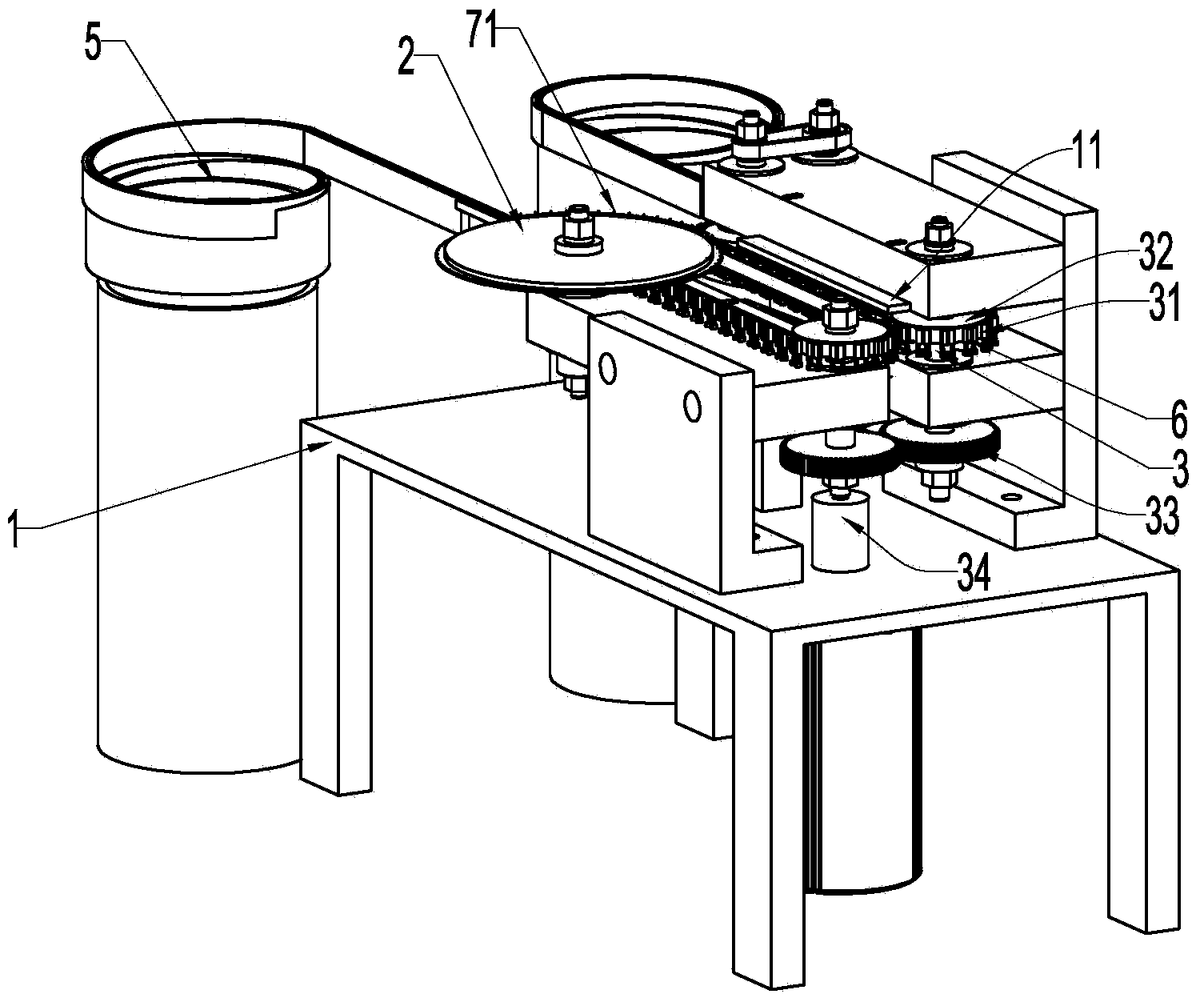

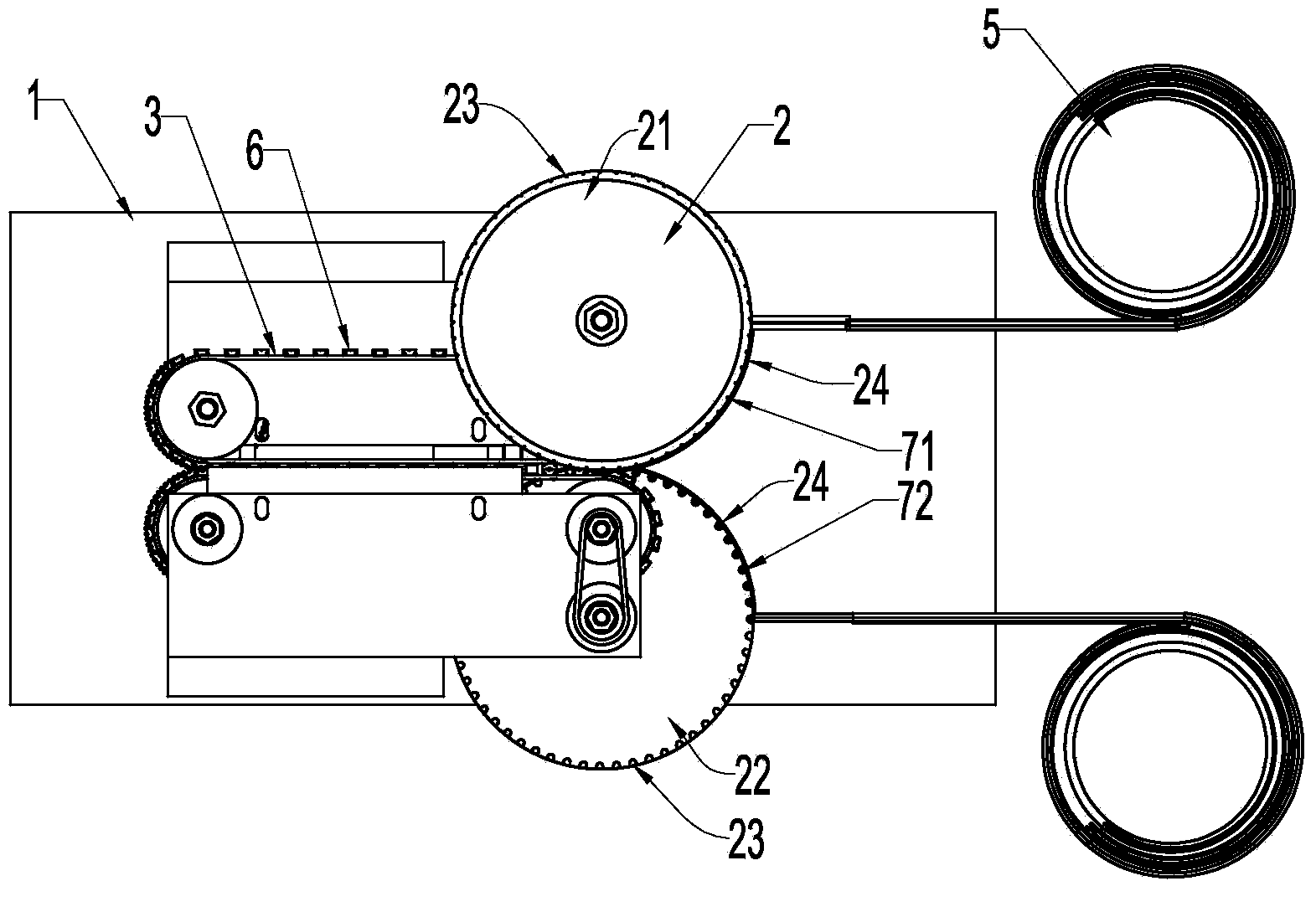

[0026] Such as figure 1 , figure 2 , Figure 6 and Figure 7 , the clamping mechanism 3 comprises two symmetrical clamping belts 31 arranged side by side and clamping assemblies 6 fixed on the clamping belts 31 at equal intervals, and a transmission wheel 32 that drives the two clamping belts 31 to run synchronously; The clamping assembly 6 includes an upper clamping block 61, a lower clamping block 62, a guide post 63 and a spring 64; the upper clamping block 61 has a small V-shaped groove 610 for clamping the arbor, and the lower clamping block 62 has a small V-shaped groove for clamping the handle cap. Large V-shaped groove 620; the lower clamping block 62 is slidably positioned on the upper clamping block 61 through the guide post 63, keeping the small V-shaped groove 610 and the large V-shaped groove 620 on the same axis, and maintaining alignment and vibration assembly; the spring 64 is sleeved on On the guide post 63, after the lower clamping block 62 loses suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com