Squeeze casting die and casting method for straight toothed spur gears

A technology of extrusion casting and gears, which is applied to the extrusion casting mold of spur-toothed cylindrical metal gears and its casting field, can solve the problems of affecting the performance of gears, low material utilization rate, and shrinkage defects of workpieces, and achieves improved cutting performance, High utilization rate of materials and the effect of eradicating dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for extrusion casting of cylindrical spur metal gear toothed blanks, comprising the following steps

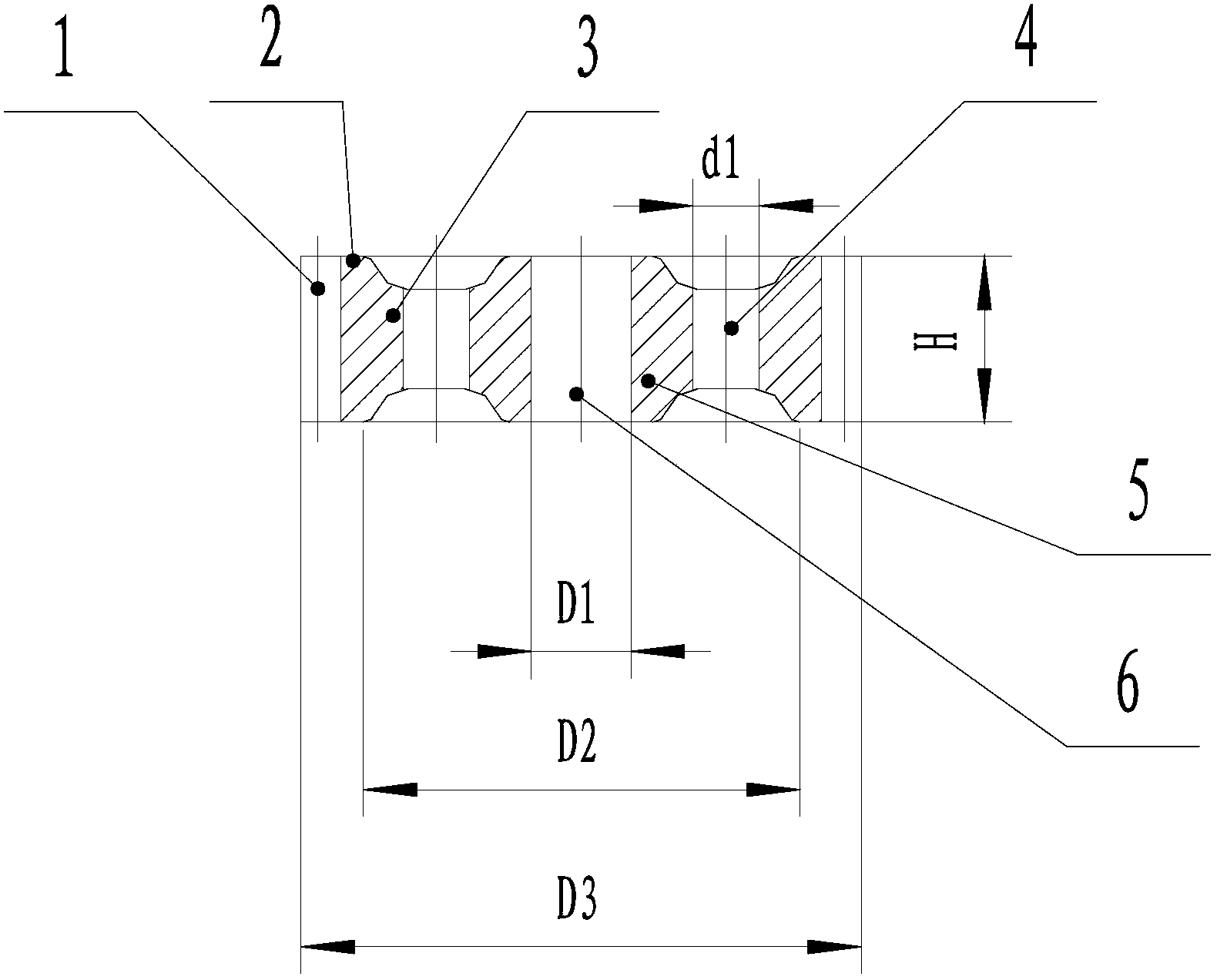

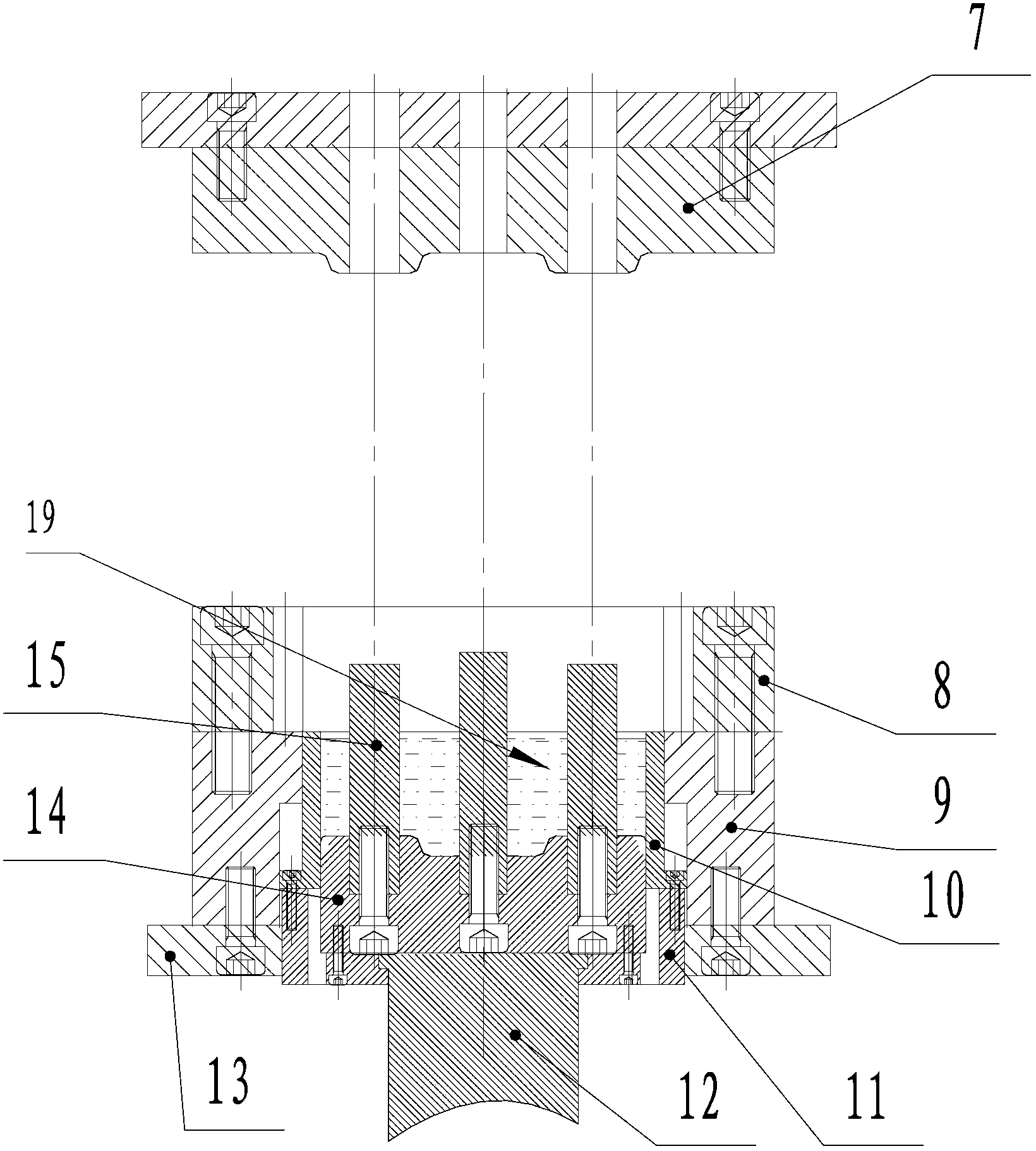

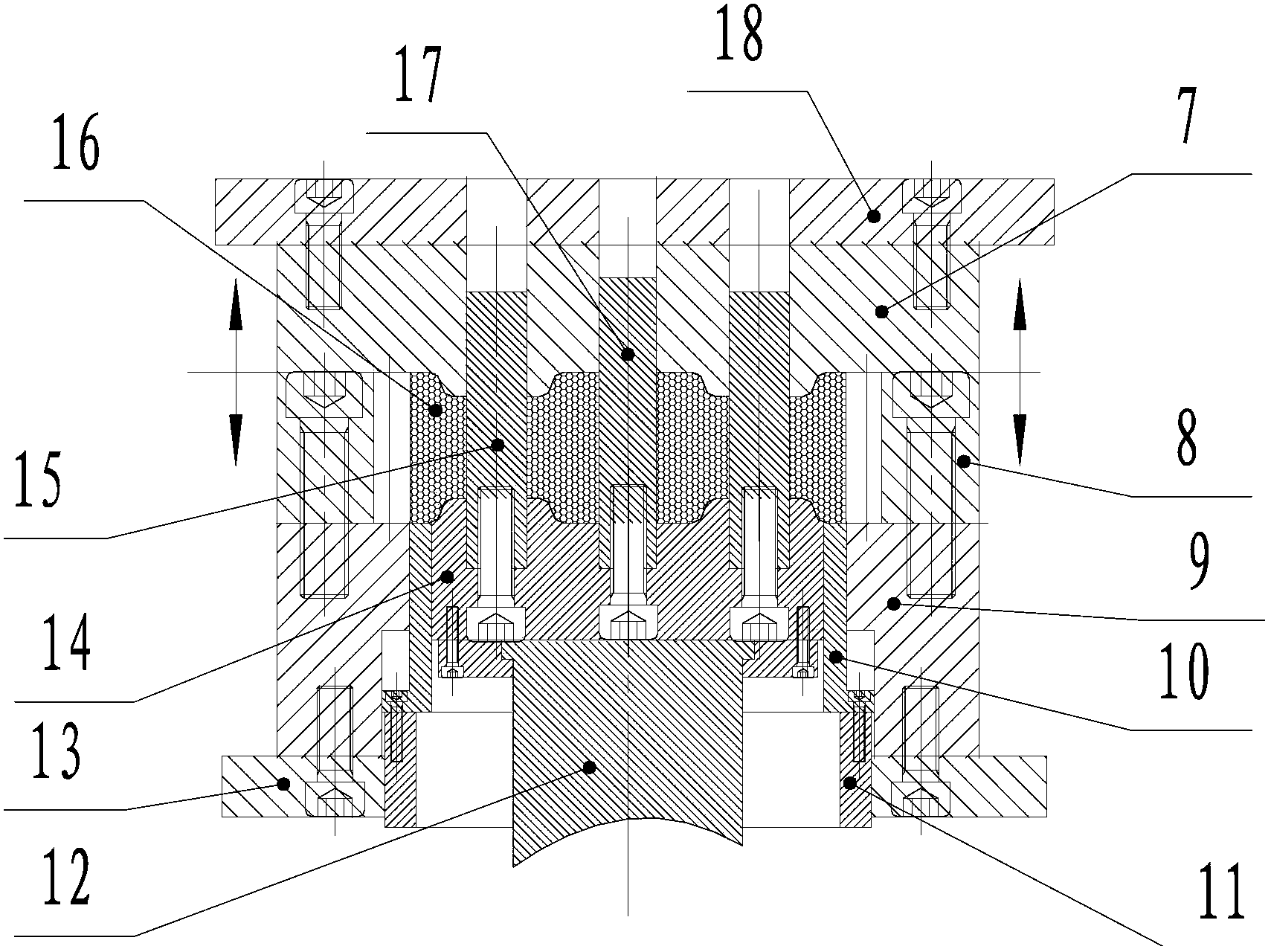

[0065] Step 1 Adjust the die: start the liquid forging machine, move the bottom die ring 10 until the upper end surface of the bottom die ring 10 is flush with the upper end face of the lower die 9, and make the bottom die 14 enter the bottom die ring 10 to the upper end face of the bottom die 14 The highest point is H from the upper end surface of the bottom mold ring 10, so that the lower end surface of the upper mold 7 is 1.2×Hmm from the upper end surface of the middle mold 8;

[0066] Step 2: Pouring the gear molten metal 19, pouring the smelted gear molten metal 19 into the pouring cavity formed by the inner surface of the bottom mold ring 10 and the upper end surface of the bottom mold 14, and stopping at 1 mm from the upper end surface of the bottom mold ring 10;

[0067] Step 3: Clamp the mold, the liquid forging motor plate drives the upper mold 7 to ...

Embodiment 2

[0072] A method for extrusion casting of cylindrical spur metal gear toothed blanks, comprising the following steps

[0073] Step 1 Adjust the die: start the liquid forging machine, move the bottom die ring 10 until the upper end surface of the bottom die ring 10 is flush with the upper end face of the lower die 9, and make the bottom die 14 enter the bottom die ring 10 to the upper end face of the bottom die 14 The highest point is (1.1)×H from the upper end surface of the bottom mold ring 10, so that the lower end surface of the upper mold 7 is 500mm from the upper end surface of the middle mold 8;

[0074] Step 2: Pouring the gear molten metal 19, pouring the smelted gear molten metal 19 into the pouring cavity formed by the inner surface of the bottom mold ring 10 and the upper end surface of the bottom mold 14, and stopping at a distance of 10 mm from the upper end surface of the bottom mold ring 10;

[0075] Step 3: Clamp the mold, the liquid forging motor plate drives t...

Embodiment 3

[0080] A method for extrusion casting of cylindrical spur metal gear toothed blanks, comprising the following steps

[0081] Step 1 Adjust the die: start the liquid forging machine, move the bottom die ring 10 until the upper end surface of the bottom die ring 10 is flush with the upper end face of the lower die 9, and make the bottom die 14 enter the bottom die ring 10 to the upper end face of the bottom die 14 The highest point is (1.2)×H from the upper end surface of the bottom mold ring 10, so that the lower end surface of the upper mold 7 is 1000mm from the upper end surface of the middle mold 8;

[0082] Step 2: Pouring the gear molten metal 19, pouring the smelted gear molten metal 19 into the casting cavity formed by the inner surface of the bottom mold ring 10 and the upper end surface of the bottom mold 14, and stopping at 20 mm from the upper end surface of the bottom mold ring 10;

[0083] Step 3: Close the mold, the liquid forging motorized plate drives the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com