Resist stripper composition

A technology of resist stripping agent and composition, applied in the preparation of detergent composition, surface active detergent composition, detergent mixture composition, etc., can solve the problems of no peeling ability and long-term maintenance peeling ability and the like , to achieve the effect of improving productivity

Active Publication Date: 2019-11-22

DONGWOO FINE CHEM CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Korean Patent Laid-Open Application No. 2009-75516 discloses a color resist stripping solution composition for TFT (Thin Film Transistor) LCD, however, the composition does not have the effect of excellent stripping ability and long-term maintenance of stripping ability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

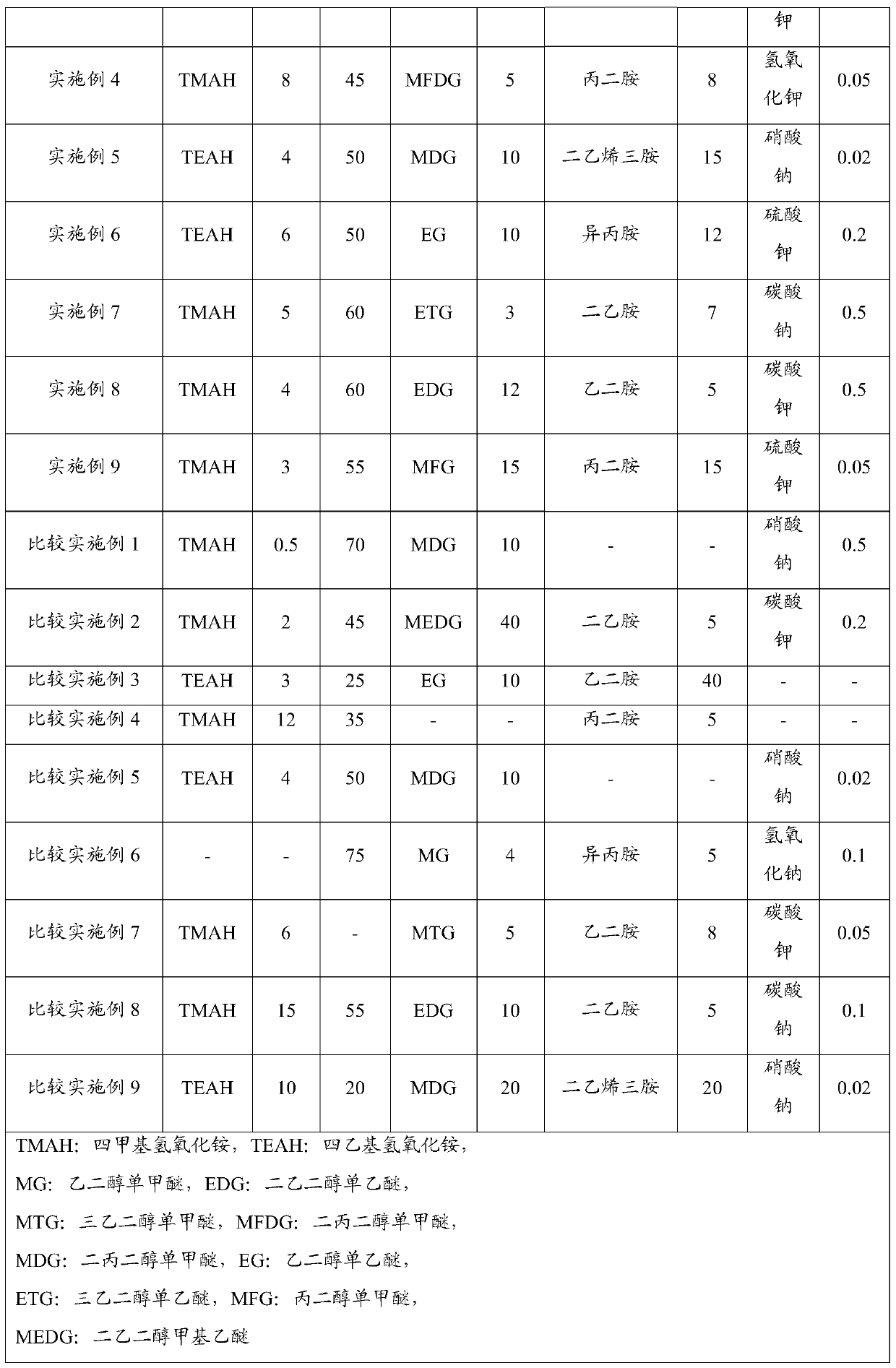

[0043] Examples and Comparative Examples

[0044] A resist stripper composition was prepared using the following components listed in Table 1 and their structural compositions (% by weight), adding water as the balance.

[0045] [Table 1]

[0046]

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A corrosion resistant agent and stripping agent composition disclosed by the present invention comprises: 1-10% by weight of organic ammonium hydroxide season, 40-80% by weight of dimethylsulfoxide, 1-25% by weight of organic solvent based on glycol ether, 1-25% by weight of alkylamine possessing 1-20 carbon atoms; 0.001-1% by weight of inorganic base or salt thereof; and the balance water. According to the corrosion resistant agent and stripping agent composition containing the above components, a colored filter corrosion resistant agent can be removed from a substrate by dissolution, so that a best stripping capability can be obtained, the colored filter plugging in a device can be reduced to the minimum level, a negative organic insulating film corrosion resistant agent, a positive organic insulating film corrosion resistant agent and the colored filter corrosion resistant agent can be stripped, and a bottom layer and various metal wirings are not damaged.

Description

technical field [0001] The present invention relates to a resist stripper composition. Background technique [0002] The color filter may be installed in a color imaging device having an image sensor such as a complementary metal oxide semiconductor (CMOS) or a charge coupled device (CCD) and actually used to generate a color image. In addition, color filters are widely used in applications of imaging devices such as plasma display panels (PDPs), liquid crystal displays (LCDs), field emission displays (FELs), light emitting devices (LEDs), and these application fields are rapidly expanding these days range. In particular, as the use of LCDs has been increasing in recent years, color filters are considered to be one of the most important devices in reproducing the color tone of LCDs. [0003] The color filter substrate includes: a black matrix that functions to shield light leakage between the red (R), green (G) and blue (B) patterns and each pixel while improving the dista...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/42

CPCC11D1/40C11D11/0047G03F7/0007G03F7/422G03F7/423G03F7/425

Inventor 尹嚆重金祐逸房淳洪

Owner DONGWOO FINE CHEM CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com