Black silane primers for improving the adhesion of adhesive tapes on glass surfaces

A primer and silane technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as being unsuitable for improving the adhesion of pressure-sensitive adhesive tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

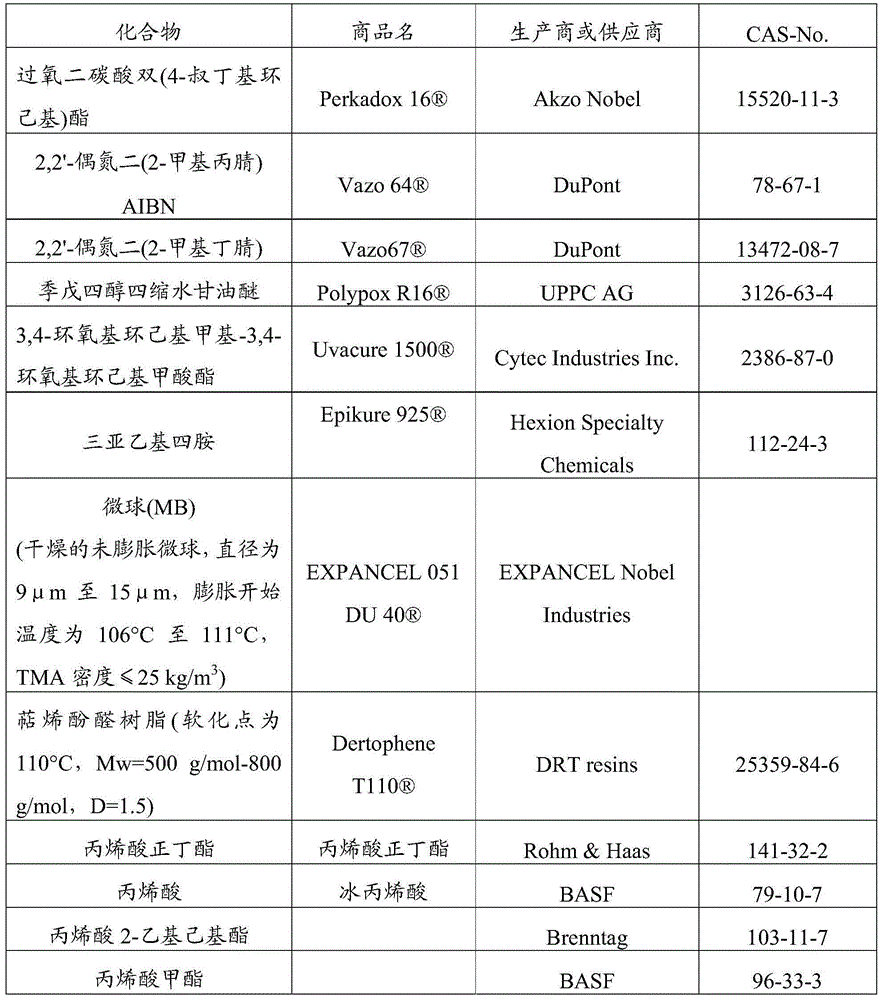

[0170] Composition of primer:

[0171]

[0172] The primer was tested with a test adhesive tape in the following manner, where the following results were obtained:

[0173]

[0174] K = cohesive rupture rate of the adhesive tape (the percentage refers to the cohesive part), and the non-cohesive part is the adhesive part.

[0175] A 5 μm thick layer of this primer on glass was opaque. The light transmittance in the wavelength range of 300 nm to 650 nm is 0%.

Embodiment 2

[0177] Composition of primer:

[0178]

[0179] The primer was tested using a test adhesive tape in the following manner, wherein the following results were obtained:

[0180]

[0181]

[0182] K = cohesive rupture rate of the adhesive tape (the percentage refers to the cohesive part), and the non-cohesive part is the adhesive part.

[0183] A 10 μm thick layer of this primer on glass was opaque. The light transmittance in the wavelength range of 300 nm to 650 nm is 0%.

Embodiment 3

[0185] Composition of primer:

[0186]

[0187] The primer was tested using a test adhesive tape in the following manner, wherein the following results were obtained:

[0188]

[0189] K = cohesive rupture rate of the adhesive tape (the percentage refers to the cohesive part), and the non-cohesive part is the adhesive part.

[0190] A 5 μm thick layer of this primer on glass was opaque. The light transmittance in the wavelength range of 300 nm to 650 nm is 0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com