A fireproof board production line

A fire-proof board and production line technology, applied in ceramic molding workshops, object stacking, ceramic molding machines, etc., can solve the problems of large space occupation, affecting work efficiency, and low production efficiency, so as to improve quality, improve production quality, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

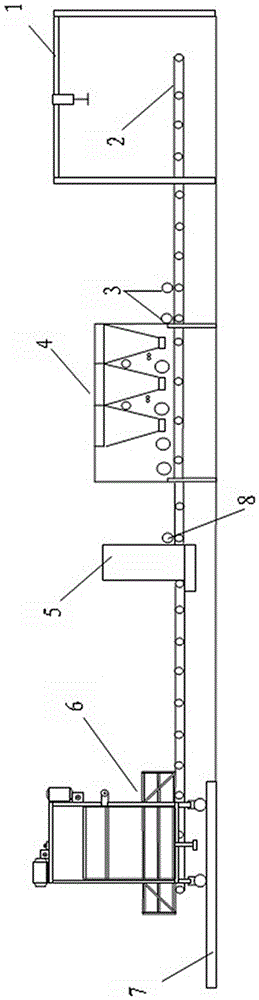

[0020] Such as figure 1 As shown, along the running direction of the material row conveyor belt 2, there are successively provided a hanging rack 1, a board releasing host 4, a shearing machine 5, a palletizer 6, and a feeding table 7 from front to back, corresponding to the material row entering the board The position of the main engine is provided with a first upper pressure roller 3 above the material row conveyor belt, corresponding to the position where the material row enters the shearing machine, and a second upper pressure roller 8 is arranged above the material row conveyor belt.

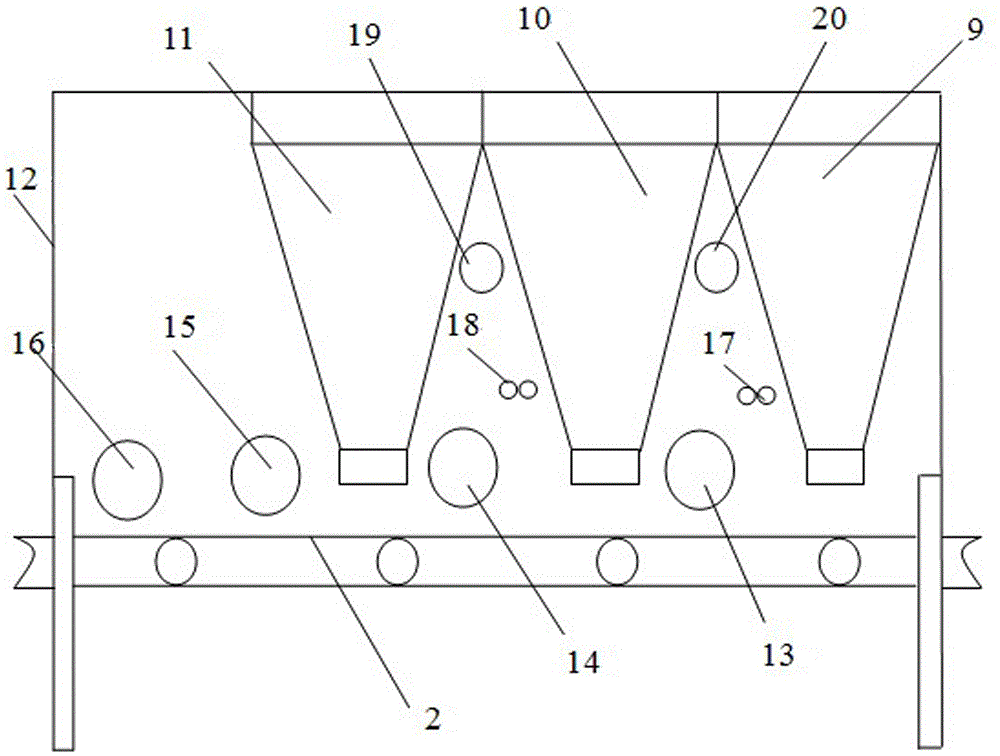

[0021] Such as figure 2 As shown, the structure of the plate releasing machine is that a hopper and a pressure roller shaft are arranged above the material row conveyor belt 2, and the shaft seats of the hopper and the pressure roller shaft are all fixed with the frame 12, along the running direction of the material row conveyor belt, from the front The first hopper 9, the second hopper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com