Electric shock prevention fixing device for isolation baffles of high-voltage switch cabinet

A high-voltage switchgear and isolation baffle technology, applied in the direction of guards/shutters to prevent contact with contacts, can solve problems such as personal accidents, achieve strong operability, prevent personal electric shock accidents, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

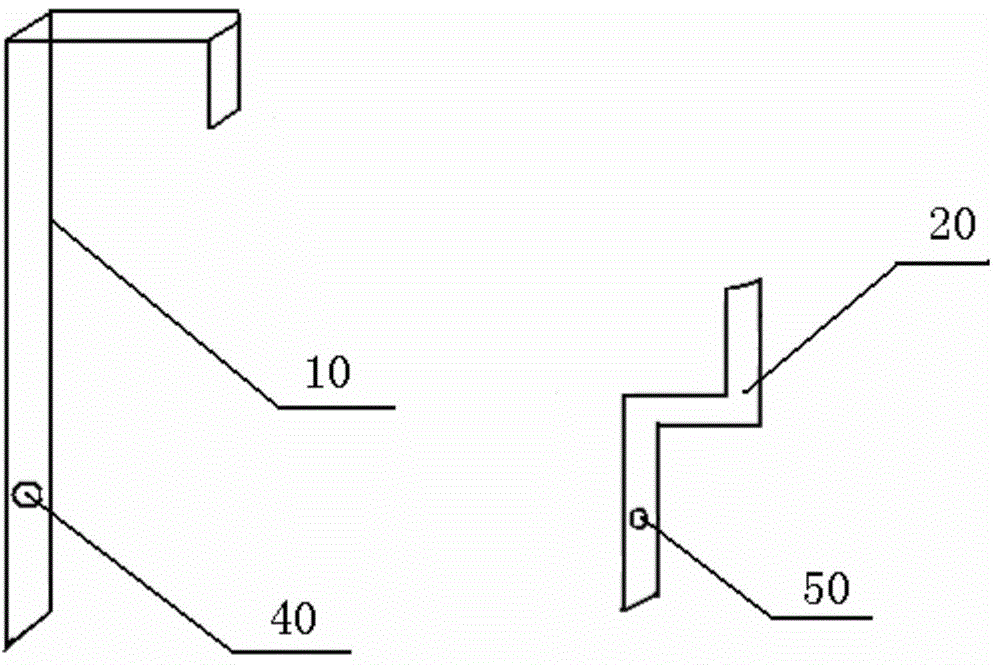

[0014] Such as Figure 1 to Figure 2 As shown, the electric shock-proof fixing device for the isolation baffle of the high-voltage switchgear of the present invention includes an upper part 10 of the clip, a lower part 20 of the clip and a lock pin 30. The lower part of the upper part 10 of the clip is provided with a first through hole 40, A second through hole 50 is provided at the bottom of the clip lower part 20 , and the locking pin 30 passes through the first through hole 40 and the second through hole 50 to fix the clip upper part 10 and the clip lower part 20 .

[0015] The shape of the upper part 10 of the clip is an inverted "L" shape, and the shape of the lower part 20 of the clip is " ” shape; the lock pin 30 can be in the form of a padlock. The upper part 10 of the clip and the lower part 20 of the clip are made of strip-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com