Huge-curtain LED screen

A technology of LED screen and giant screen, applied in the field of giant screen LED screen, can solve the problem of slow disassembly and assembly speed of LED screen, and achieve the effect of shortening assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

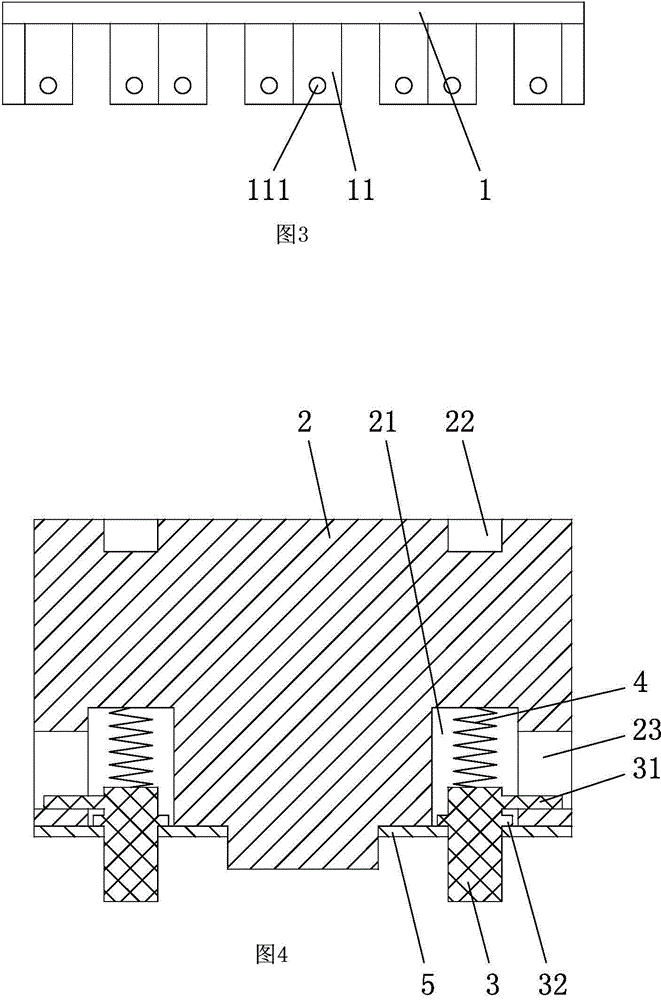

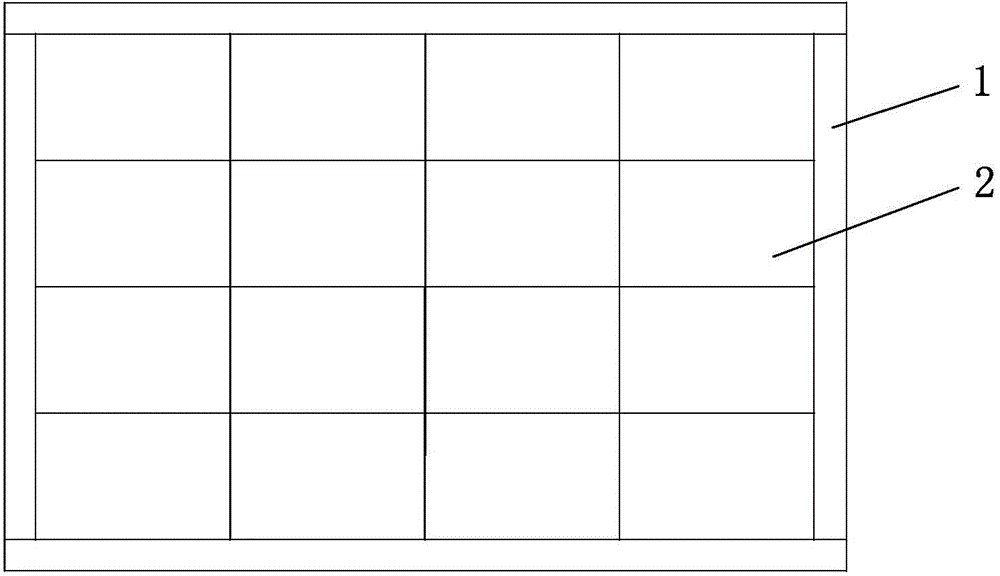

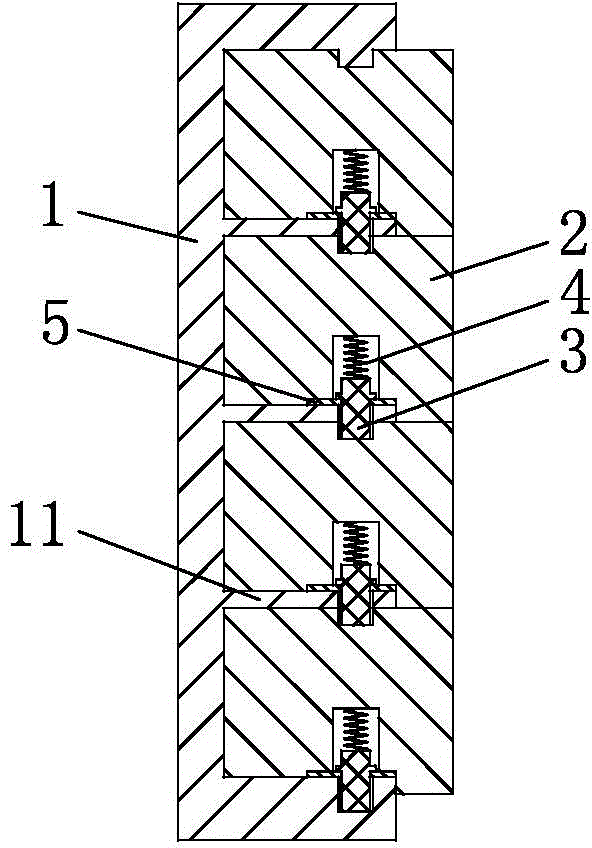

[0017] refer to figure 1 , image 3 and Figure 4 , a giant screen LED screen, including a frame 1 and several LED screens 2 arranged on the frame 1, a positioning plate 11 is provided on the frame 1, a positioning hole 111 is provided on the positioning plate 11, and a mounting groove is provided on the LED screen 2 21. The locking groove 22 and the cover plate 5, the axis of the installation groove 21 and the axis of the locking groove 22 are located on the same straight line, the cover plate 5 can cover the opening of the installation groove 21, and the cover plate 5 passes through the fastener It is fixed on the LED screen 2, and the cover plate 5 is provided with a through hole.

[0018] refer to figure 2 , image 3 and Figure 4 , the mounting groove 21 is provided with an axially movable limit rod 3, the limit rod 3 is provided with an operating rod 31 and an annular rib 32, the annular rib 32 is located below the operating rod 31, and the operating rod 31 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com