Sliding plate valve for dry-mixed mortar storage tank

A dry powder mortar and storage tank technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of short service life, difficulty in closing the gate, backlog, etc., and achieve the effect of labor-saving, reliable closing or opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

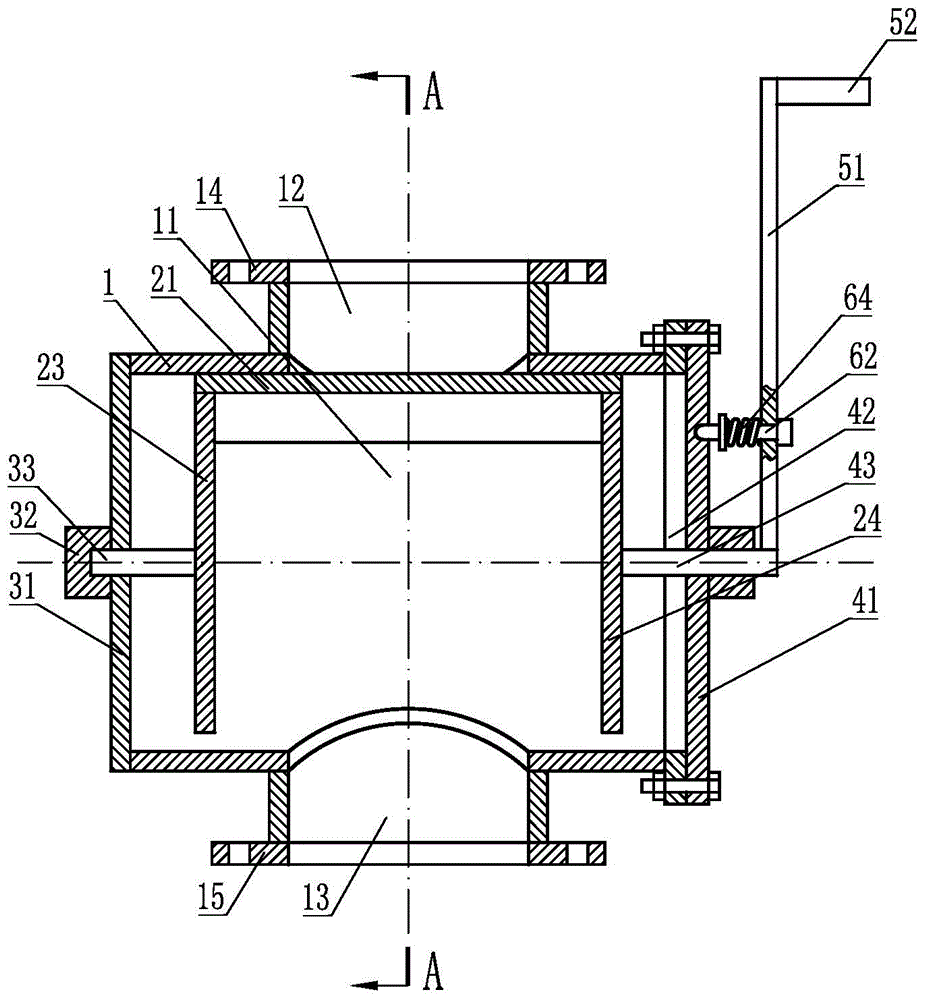

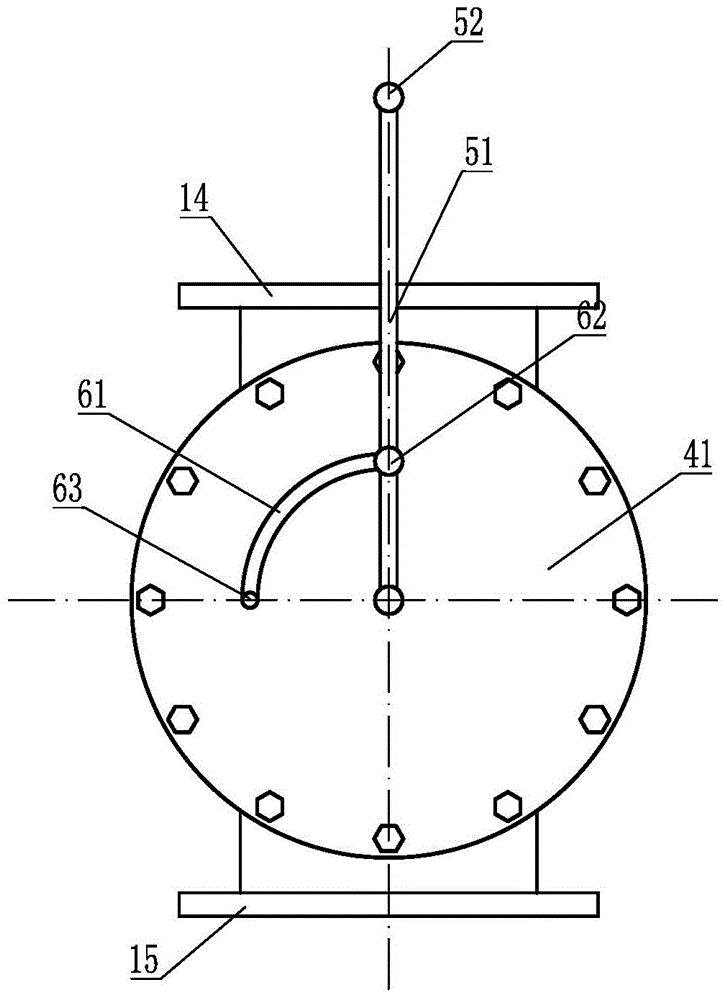

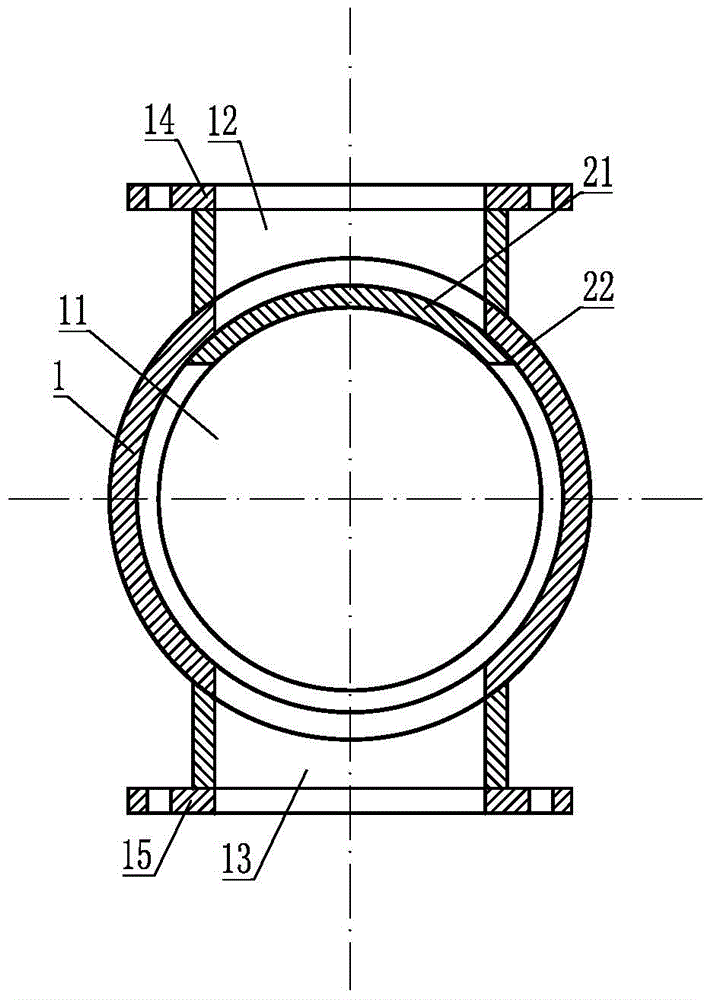

[0023] Such as figure 1 with figure 2 As shown, the slide valve for the dry powder mortar storage tank is installed on the discharge end of the dry powder mortar storage tank, and includes a valve seat 1. The valve seat 1 is provided with a cylindrical valve inner cavity 11, and the valve seat is provided with A feed channel 12 perpendicular to the valve inner cavity 11 and communicated with the valve inner cavity 11, and a discharge channel 12 perpendicular to the valve inner cavity 11 and communicated with the valve inner cavity 11 is provided on the valve seat passage 13, the valve seat is provided with a feed flange 14 and a discharge flange 15; the valve inner chamber 11 is equipped with an arc-shaped rotating slide plate 21 for blocking the feed passage 12, as image 3 with Figure 4 As shown, when the arc-shaped rotating slide plate 21 is closed, the edge of the extruded material is provided with a material cutting edge, such as Figure 5 As shown, when the slide va...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, the difference is: as Image 6 with Figure 7 As shown, when the arc-shaped rotating slide plate 21 is closed, a triangular tip 25 is provided on the edge of the extruded material, and a material cutting edge is provided on the edge of the triangular tip 25 .

[0027] When the slide valve is closed, the triangular tip 25 of the arc-shaped rotating slide plate 21 separates the material to both sides while dividing the material up and down, slowly blocking the feed channel 12, and the triangular tip 25 makes the arc rotate The resistance received by the sliding plate 21 when it rotates and closes is further reduced, so that the closing operation of the sliding plate valve is more labor-saving, and the situation that the arc-shaped rotating sliding plate 21 is stuck will not occur, and the service life of the sliding plate valve can be extended.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com