Wind tower flange ellipse overproof fire correction method

A correction method and flange technology, applied in wind power generation, wind engines, wind turbine components, etc., can solve the problems of flange ellipticity out-of-tolerance, reduce work efficiency, increase production costs, etc., to improve production efficiency, operation Convenience and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

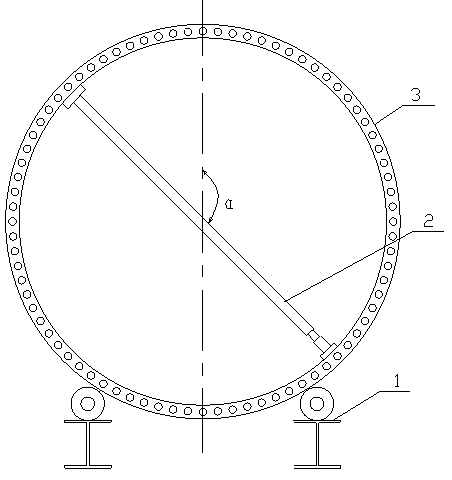

[0019] Such as figure 1 It shows a specific embodiment of a method for correcting a wind tower flange ellipse out-of-difference fire attack according to the present invention, which includes the following steps:

[0020] A. Place the wind tower section on the roller frame 1;

[0021] B. Measure the inner diameter of the flange with a laser rangefinder at every 5 holes at the fixed position of the flange 3 on the side of the wind tower tube section, and record the value;

[0022] C. Use profile support 2 to support the flange at the point where the inner diameter of the flange is the smallest, and stop when it is 5mm larger than the design value, and support the contact part between the support and the flange with a horse board;

[0023] D. At the point where the maximum recorded value is out of tolerance, rotate the straight brace to the position where one end of it forms an angle α with the vertical center line of the flange, and α is 135°, and then weld the inner and outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com