A compact micro gas turbine

A micro gas turbine, compact technology, applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of long distance, large volume, large air flow pressure loss, etc., and achieve high efficiency, small volume, and shorten the effect of axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

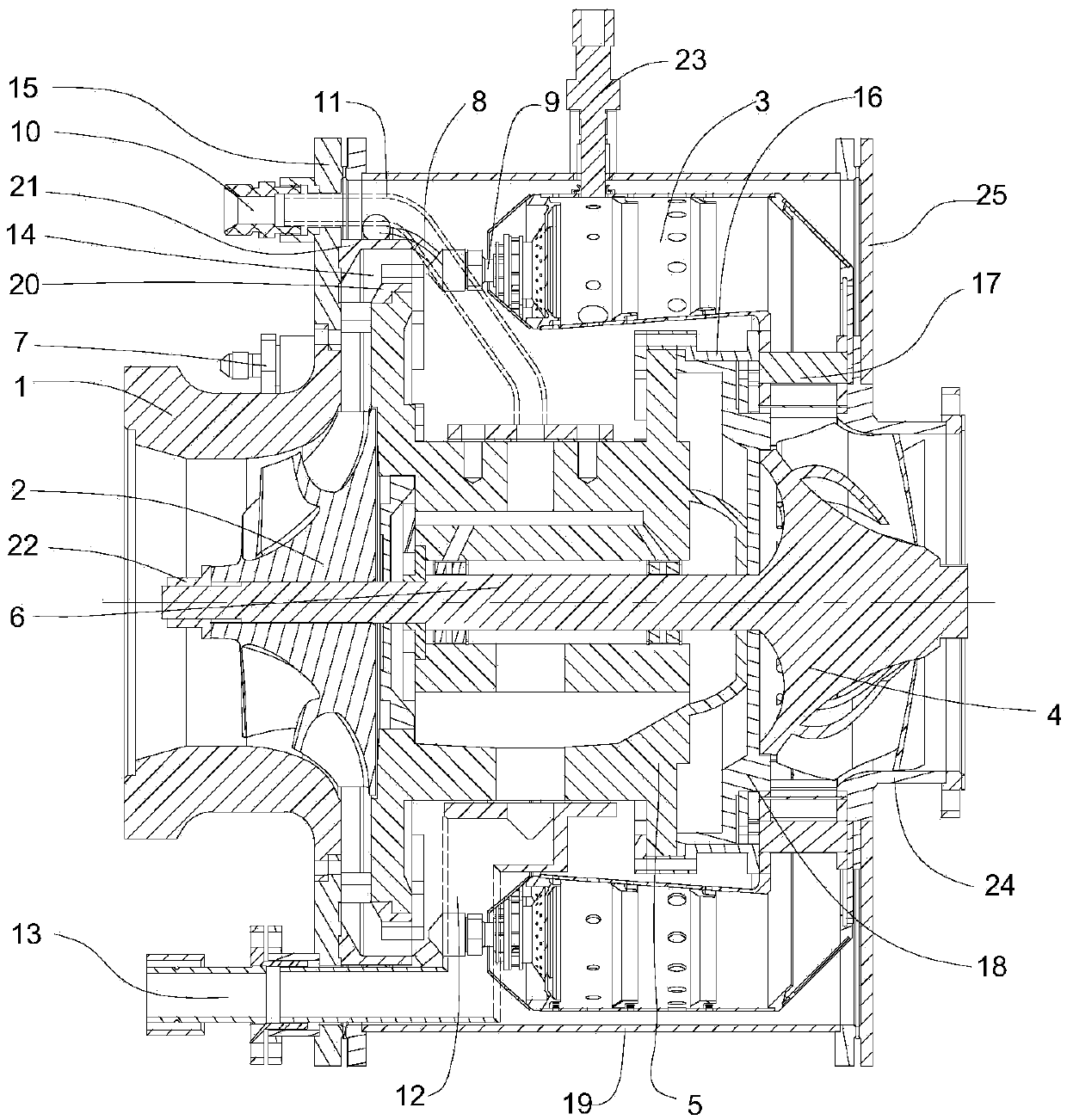

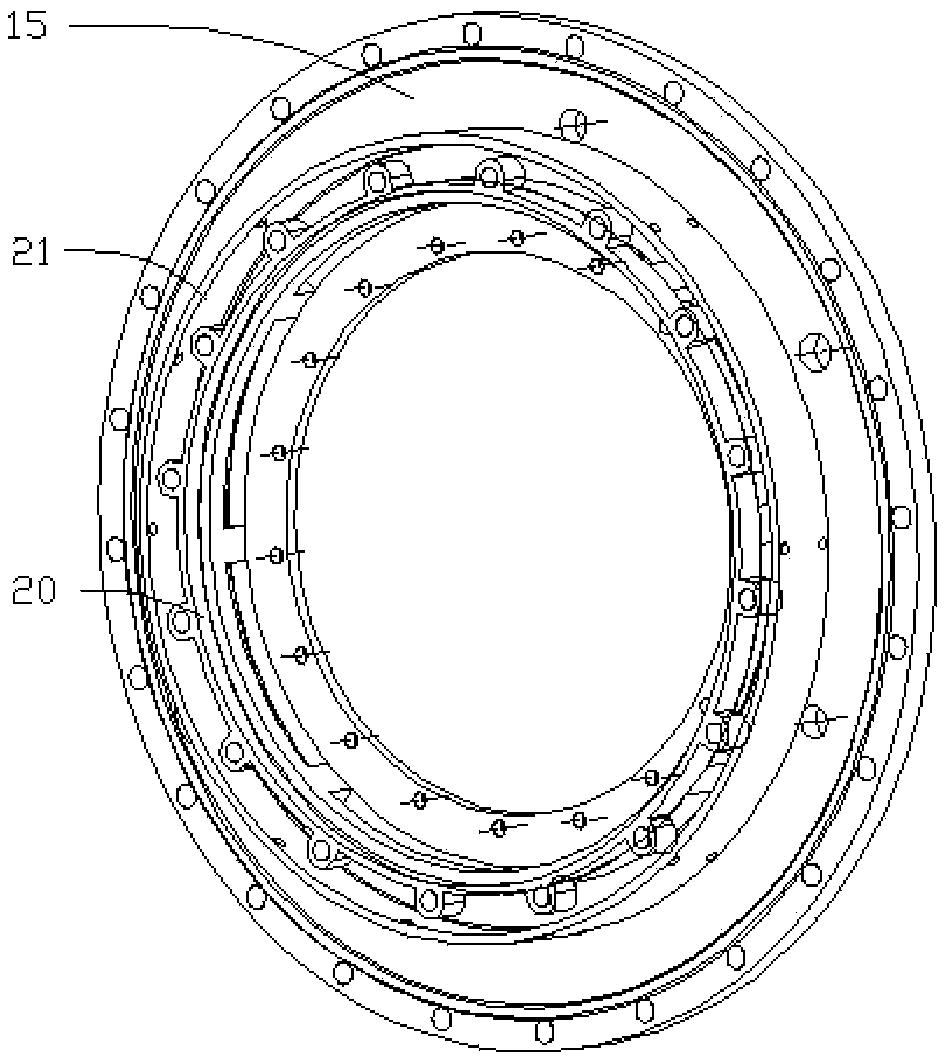

[0021] A micro gas turbine of this embodiment comprises a compressor 2, a combustion chamber 3, a turbine 4, a shaft installation body 5, a shaft 6, and a casing 19; the compressor 2 is a single-stage centrifugal compressor; the combustion chamber 3 is a full annular combustion chamber; turbine 4 is a single-stage centripetal turbine; as figure 1 As shown, the air inlet 1 is connected with the front flange 15 by screws, and installed at the front end of the compressor 2, the air enters the compressor through the air inlet 1; the diffuser inner ring 20 and the diffuser outer ring 21 are welded on the front on flange 15 (eg figure 2 As shown), the inner ring 20 of the diffuser has a bolt hole, and the inner ring 20 of the diffuser fits with the outer diameter of the front end of the shafting installation body 5, and the shafting installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com