Y-type cast-in-place concrete column formwork system and construction method thereof

A technology of concrete columns and column formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems that cannot be solved, high engineering cost, occupation, etc., and solve the problem of curve chamfering Problems, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

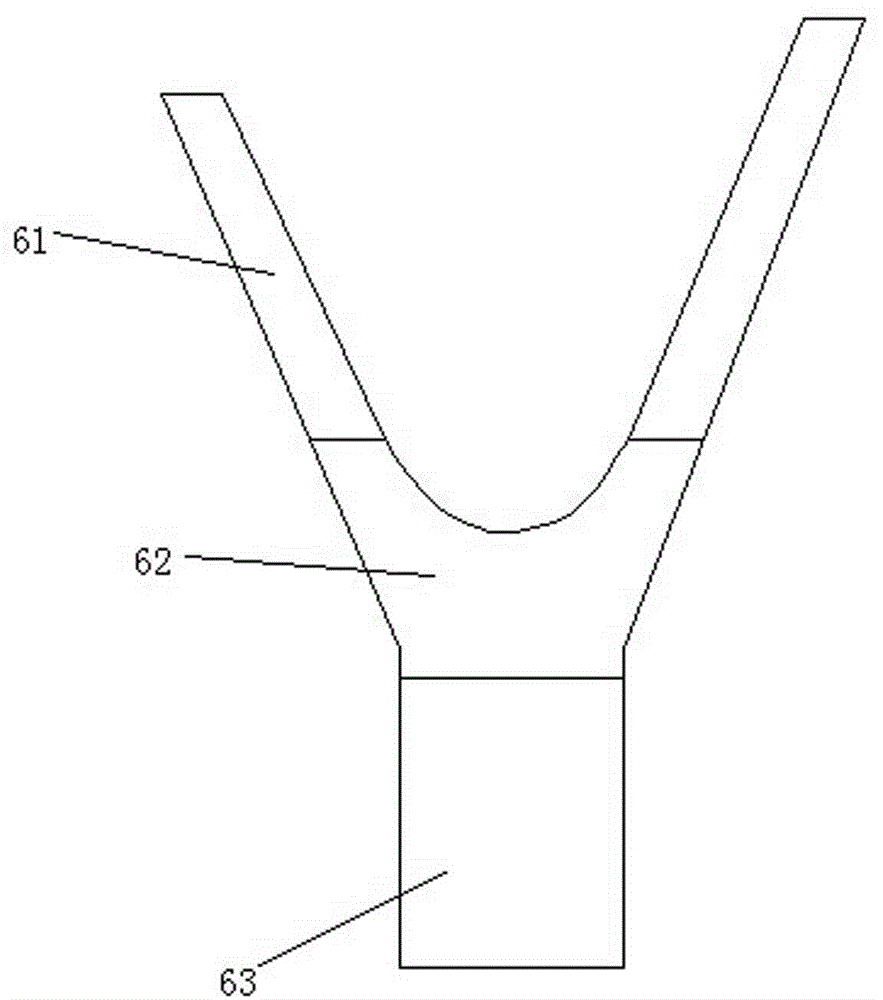

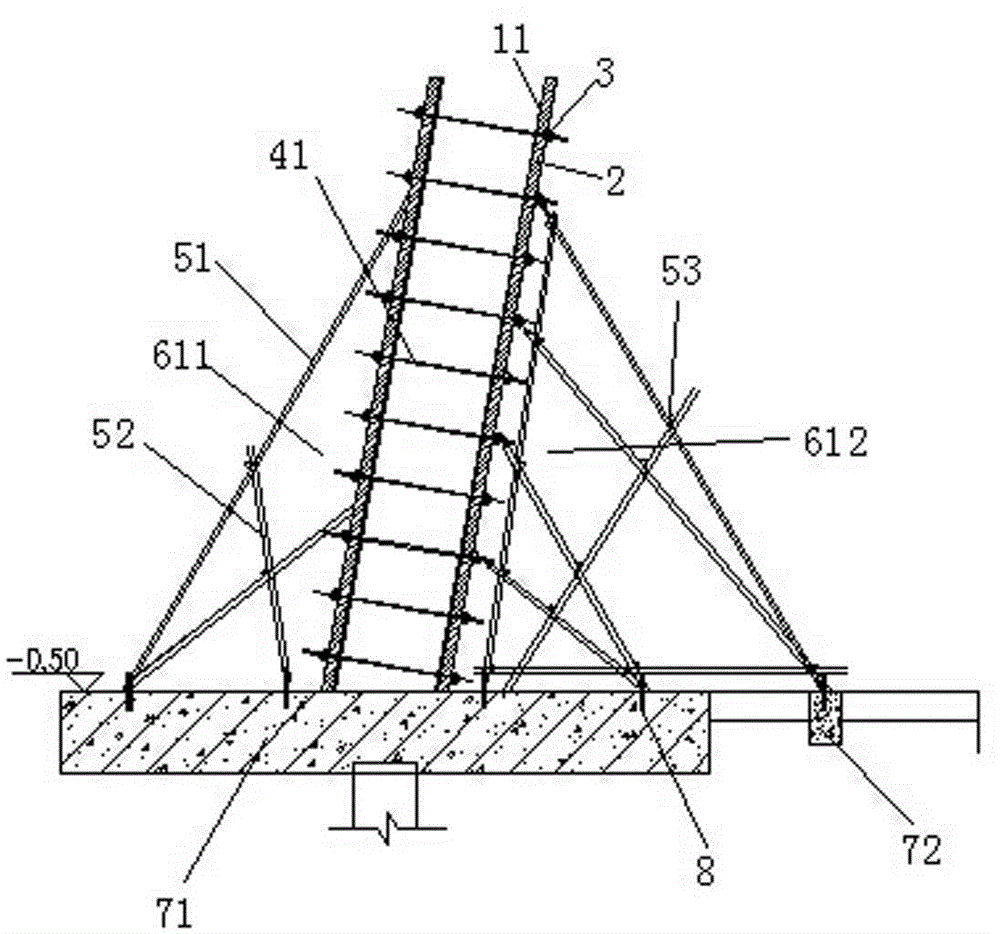

[0032] The Y-shaped column is an important structural support component of the stadium, and it is also the main manifestation of the stadium's architectural effect. There are 14 Y-shaped columns in the stadium, and the Y-shaped columns are all raised from the foundation cap at an elevation of -0.500m, and at an elevation of 6.300m The Y-shaped column is divided into two sub-pillars. The elevation of the column top varies from 17.921m to 29.060m. The vertical thickness of the column section is 1m, and the width decreases from 4.8m to 1.3m. The vertical direction is at an angle of 10°, inclined to the outside of the stadium, and twisted around the center of the stadium, facing the center of the stadium, and divided into two functional areas in the east and west of the stadium in an arc shape. The edges of the corrugated corners are all rounded with a radius of 100mm.

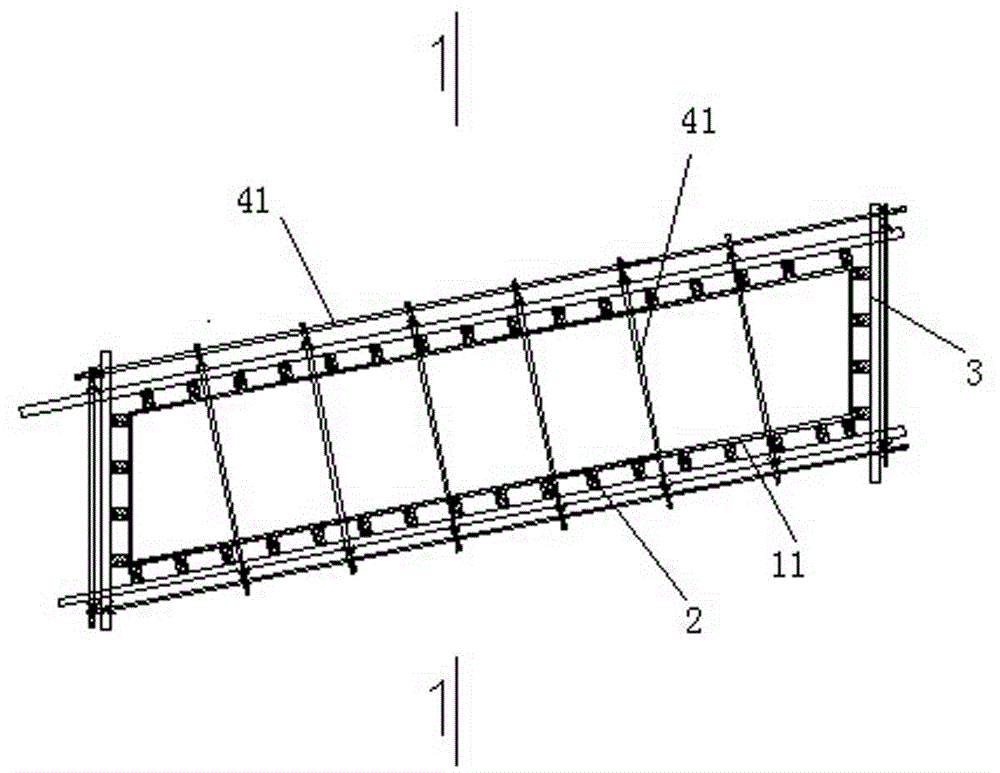

[0033] The Y-shaped cast-in-place concrete column formwork system consists of a column root formwork system, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com