A curtain wall panel dry-hanging installation fastener

A technology for installing fasteners and plates, applied in the direction of walls, building components, buildings, etc., can solve problems such as limited construction methods, difficult to remove, repair or replace, and affect progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

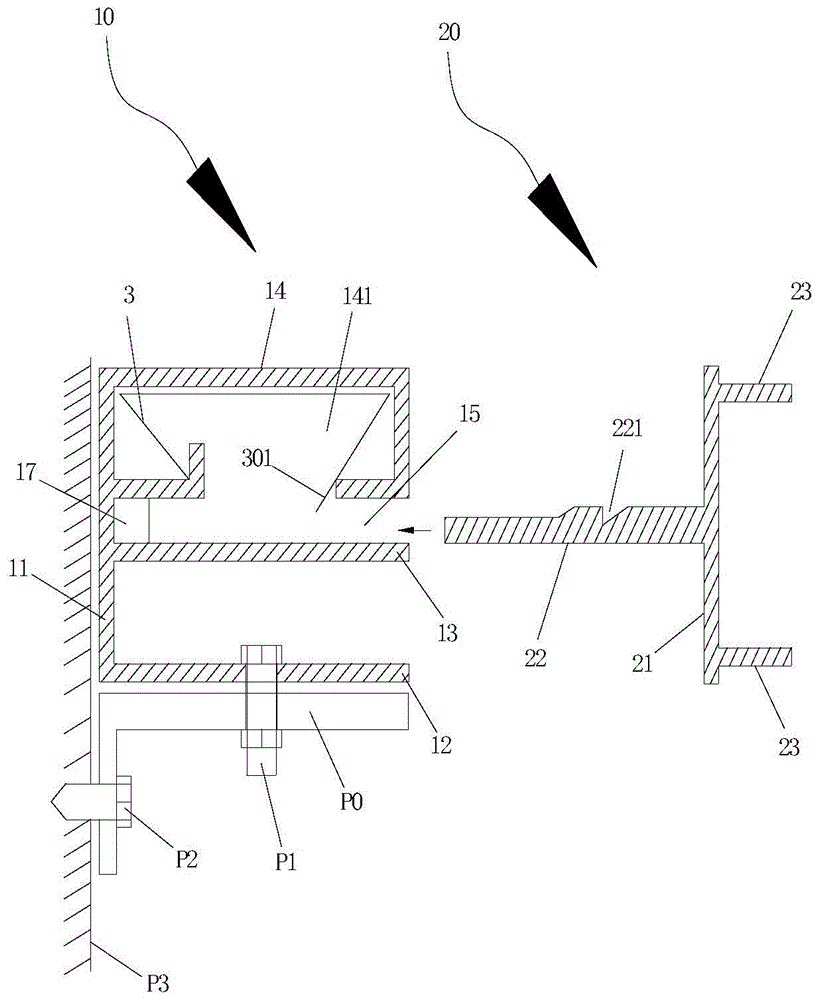

[0022] see figure 1 , the present embodiment is provided with a base 10, a hook 20 and a circlip 3, and the base 10 and the hook 20 are elongated integral profiles. figure 1 The middle mark P0 indicates the backbone.

[0023] Described base 10 is provided with bottom wall 11, left vertical wall 12, middle vertical wall 13 and right vertical wall 14; , A slot 15 is formed between the neutral wall 13 and the right wall 14 . The clip spring 3 is disposed in the clip spring installation groove 141 , and one end 301 of the open end of the clip spring 3 extends into the slot 15 . The left vertical wall 12 and the central vertical wall 13 are single straight walls, and the right vertical wall 14 is composed of two bent walls, and the circlip mounting groove 141 is formed between the two bent walls. The bottom of the slot 15 is provided with an elastic pad 17, and the elastic pad 17 is a rubber pad.

[0024] Described hook is provided with base wall 21, rear insertion wall 22 and ...

Embodiment 2

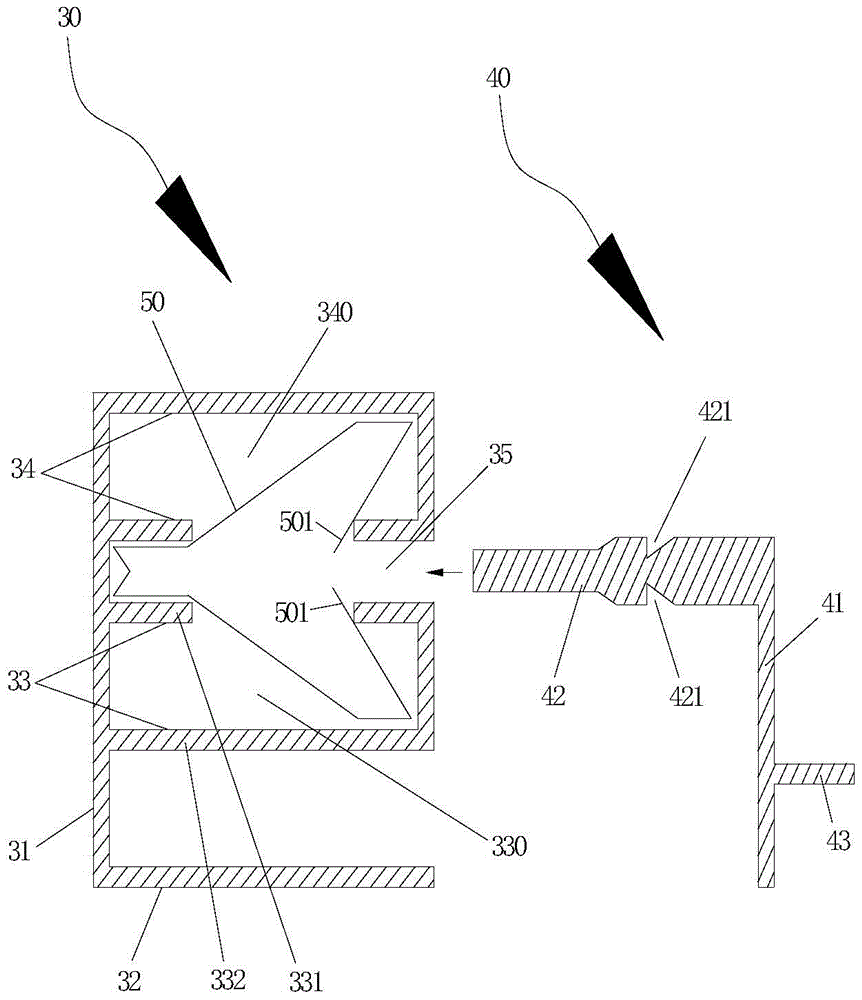

[0027] The present invention is provided with base 30 hook 40 and jumper 50, and base 30 and hook 40 are elongated integral profiles.

[0028] The base 30 is provided with a bottom wall 31 , a left vertical wall 32 , a central vertical wall 33 and a right vertical wall 34 . The left upright wall 32 , the middle upright wall 33 and the right upright wall 34 are all perpendicular to the bottom wall 31 , and the structures of the middle upright wall 33 and the right upright wall 34 are the same and set opposite to each other. The neutral wall 33 and the right vertical wall 34 are respectively provided with jumper mounting grooves 330 and 340, and a slot 35 is formed between the neutral wall 33 and the right vertical wall 34, and the slot 35 is also a jumper mounting groove. The snap ring 50 is disposed in the snap ring installation grooves 330 , 340 and the slot 35 , and the two ends of the open end of the snap ring 50 extend into the slot 35 . The left vertical wall 32 is a sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com