Networking method for DC side network operation of dual power supply rectification system

A technology of rectification system and networked operation, applied in the direction of parallel operation of DC power supply, can solve problems such as non-allowance, and achieve the effect of improving reliability, improving system reliability, and simplifying system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

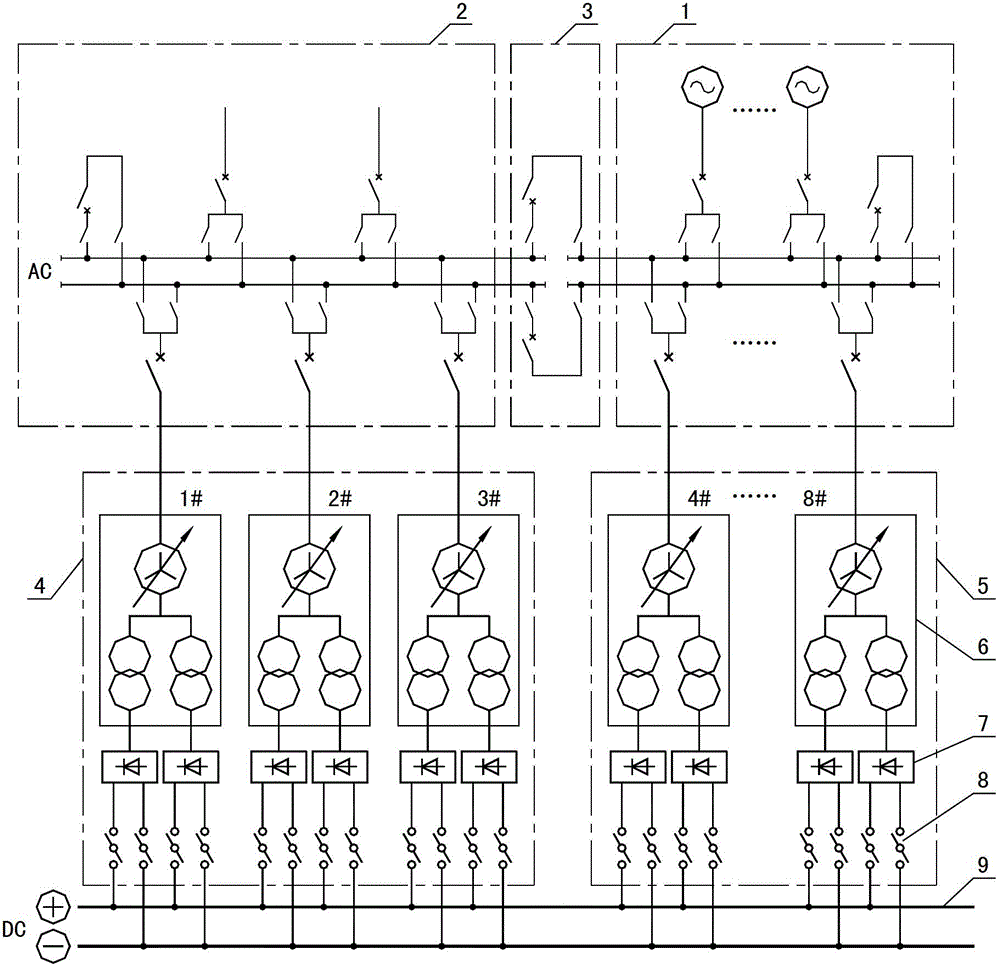

[0021] Below with the accompanying drawings figure 1 The present invention is further described.

[0022] A networking method for networked operation of the DC side of a rectifier system powered by a dual power supply. The rectifier unit 5, the voltage regulating rectifier transformer group 6; the power distribution device 1 powered by the power supply of the power plant is connected to the power distribution device 2 of the system power supply through the AC power contact switch 3;

[0023] The first and second rectifier units 4 and 5 are composed of a plurality of voltage regulating rectifier transformer groups 6, rectifiers 7, and DC isolating switches 8; the first and second rectifier units 4 and 5 are connected to a DC bus 9 together .

[0024] The first rectifier unit is composed of three or more rectifiers; the second rectifier unit is composed of five or more rectifiers.

[0025] The output terminals of the voltage regulation and rectification transformer group 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com