Scheduling method based on bottleneck procedure

A bottleneck process and product technology, applied in data processing applications, forecasting, instruments, etc., can solve the problem of manual production scheduling not being able to optimize production scheduling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

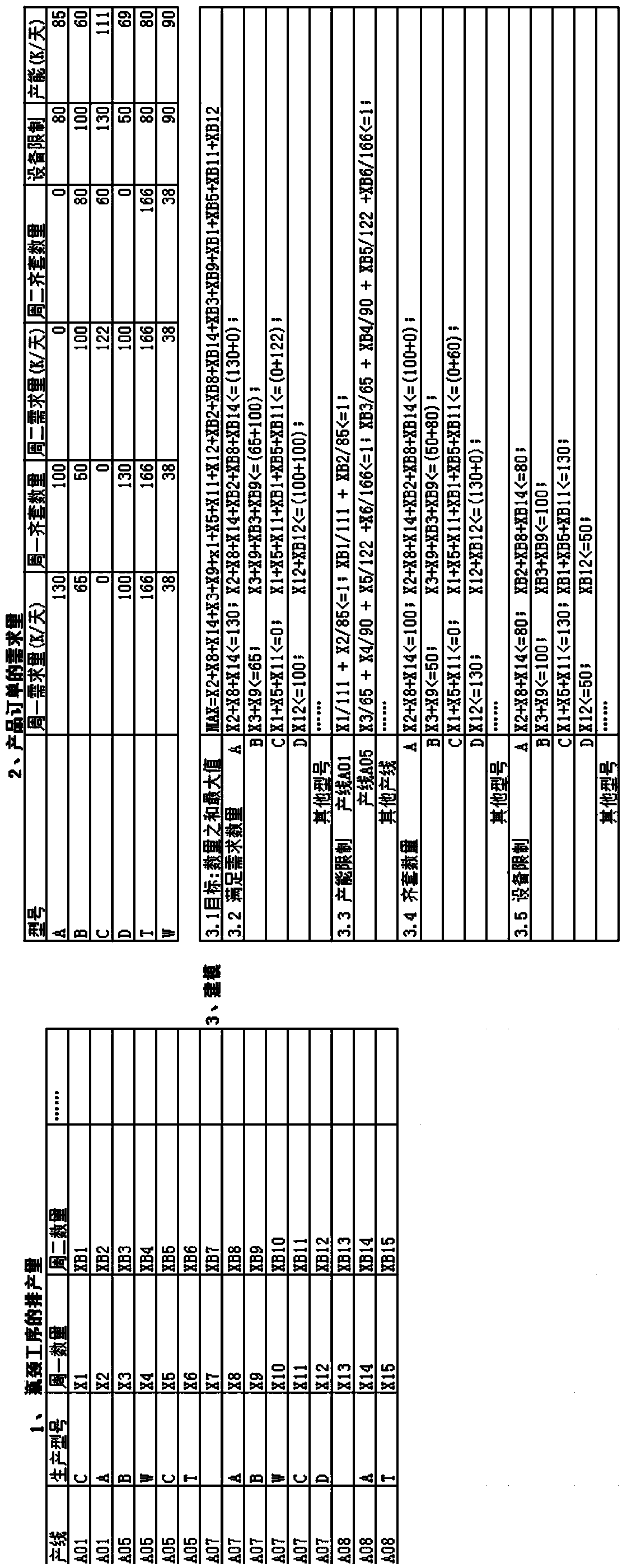

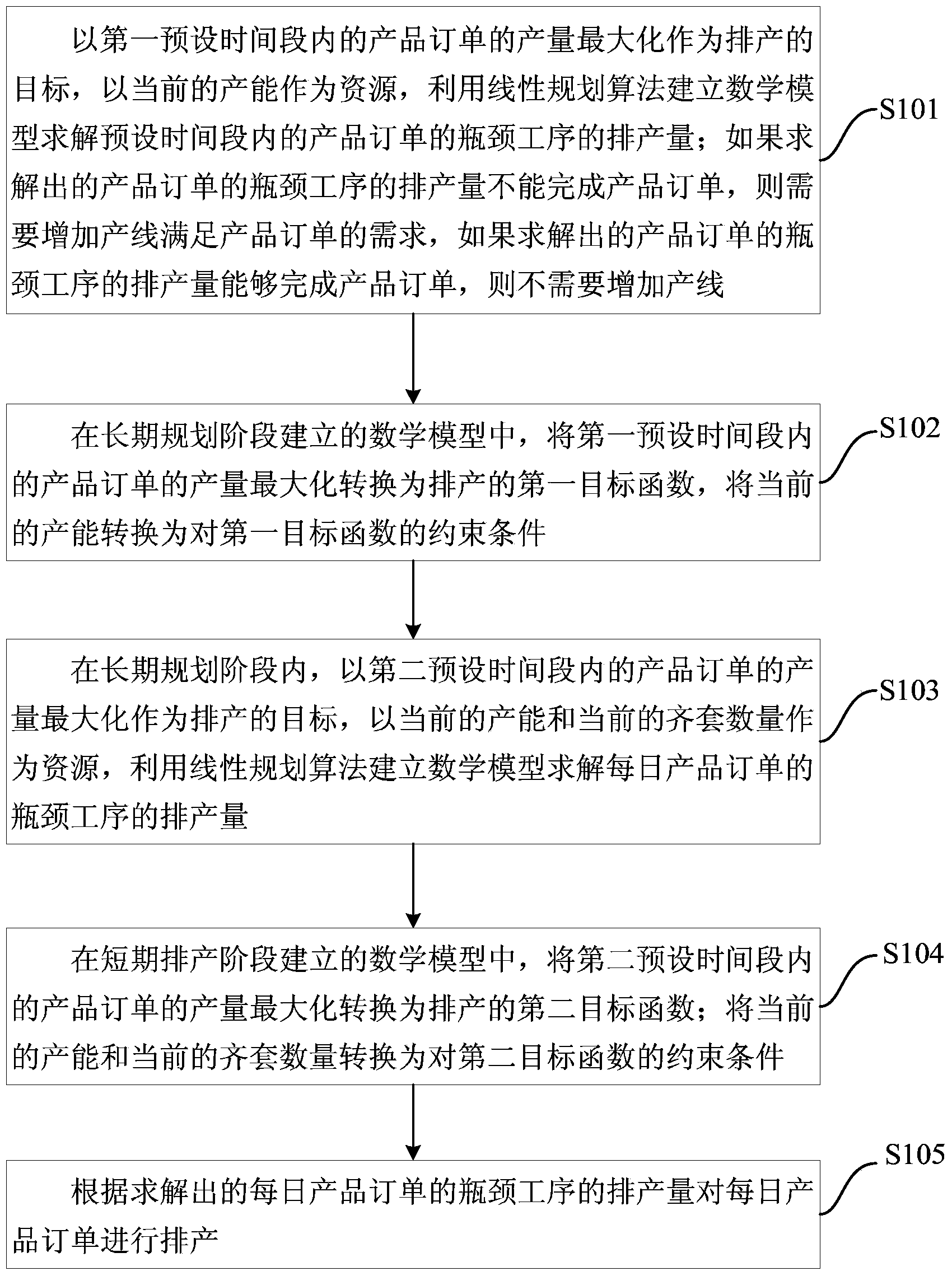

[0048] Use the linear programming algorithm to establish a mathematical model for the long-term planning stage, figure 2 Shows the mathematical model established for the long-term planning phase using the linear programming algorithm according to an embodiment of the present invention, such as figure 2 As shown, the first part is the output of the bottleneck process, in figure 2 Including four production lines are A01, A05, A07, A08, production line A01 assembles two types of parts A and C, production line A05 assembles four types of parts B, W, C, T, production line A07 assembles A , B, W, C, D five types of parts, production line A08 assembles A, T two types of parts, the following four types of A, B, C, D parts are used as examples to illustrate, other types of parts the same way.

[0049] figure 2 The second part is the demand quantity of the product order, which is the quantity of each type of parts in the product order that needs to be assembled within a preset ti...

Embodiment 2

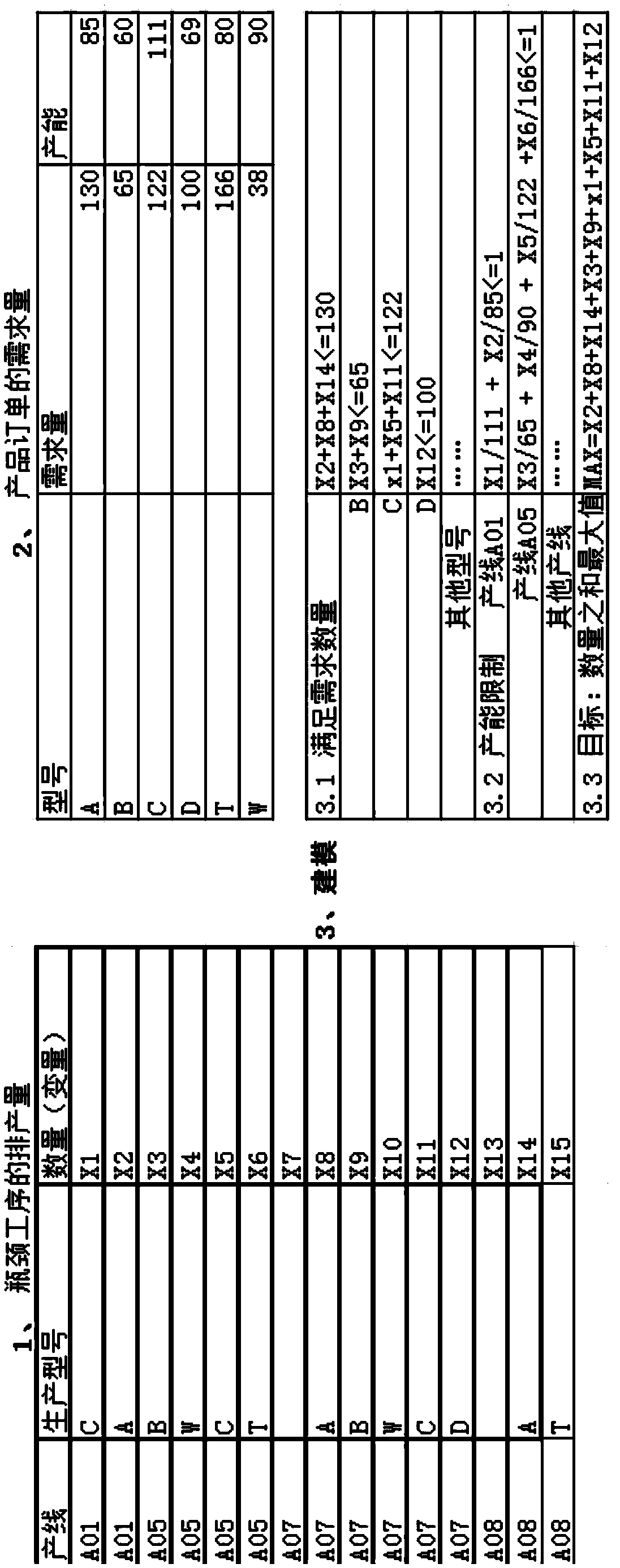

[0068] Since the orders of one month or one week will not change greatly, it can be used as the basis for accurate and all-process production scheduling, and the linear programming algorithm is used to establish a mathematical model for the short-term production scheduling stage. image 3 It shows the establishment of a mathematical model of the short-term production scheduling stage using a linear programming algorithm according to an embodiment of the present invention, such as image 3 As shown, the first part is the output of the bottleneck process of the daily product order, in image 3 Including four production lines are A01, A05, A07, A08, production line A01 assembles two types of parts A and C, production line A05 assembles four types of parts B, W, C, T, production line A07 assembles A , B, W, C, D five types of parts, production line A08 assembles A, T two types of parts, the following four types of A, B, C, D parts are used as examples to illustrate, other types of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com