Tool box

A tool box and entity technology, applied in the field of tool boxes, can solve the problems of high price and cost, insufficient strength, rigidity, heavy weight, etc., and achieve the effect of good usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will further describe the technology of the present invention in conjunction with the accompanying drawings of the embodiment, which will help the public to understand the technical content and effect of the case, but the description of the embodiment does not constitute a limitation to the technical solution. All transformations that are merely equivalent in form should be regarded as the scope of the technical solution of this case.

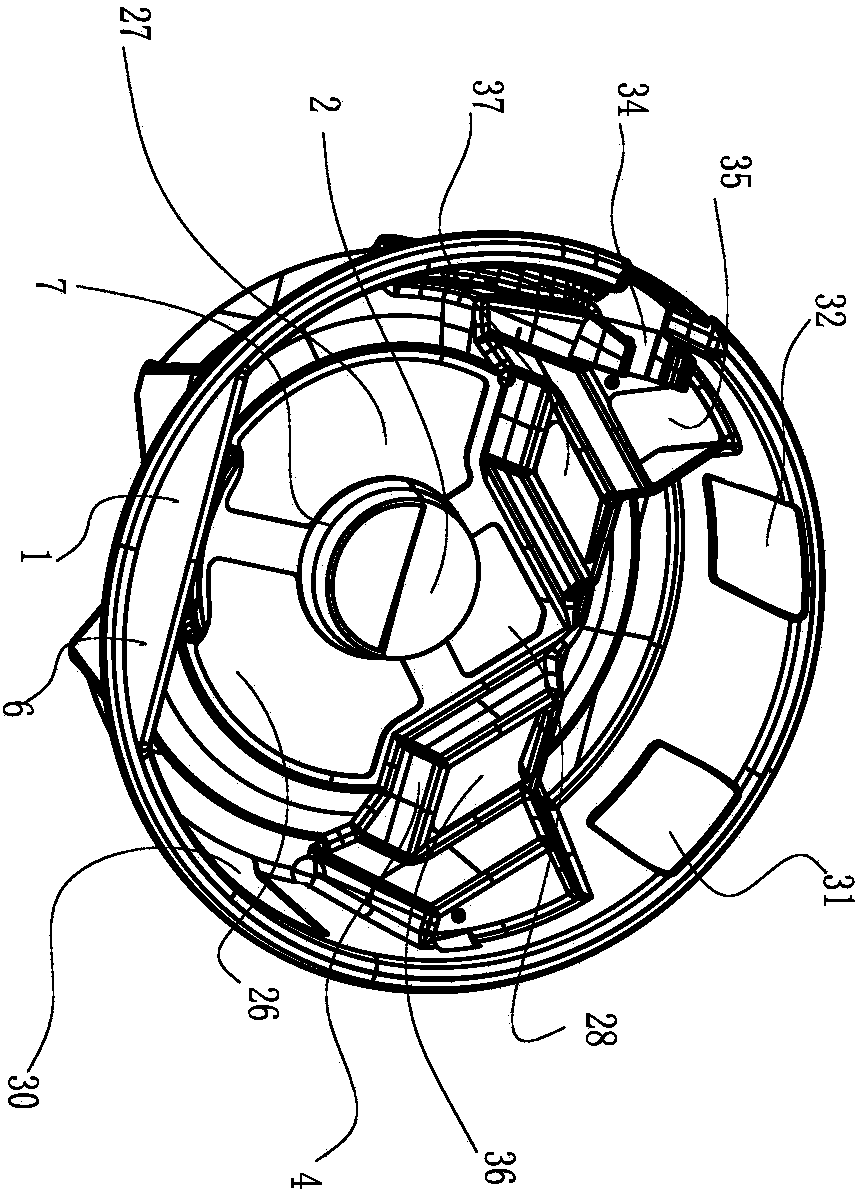

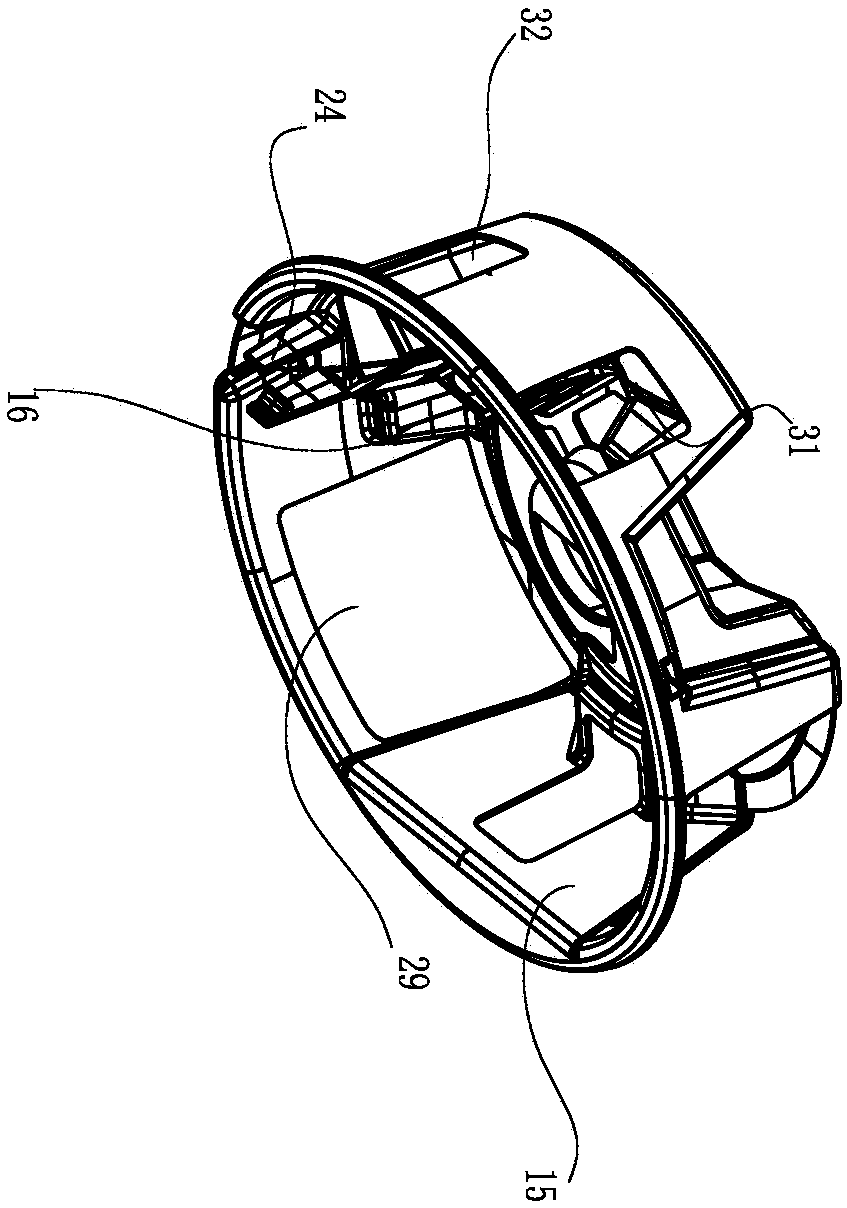

[0030]It can be seen from the attached drawings that the reinforced structures of the tool box, the economical holes set up to reduce costs, and the relevant geometric elements specially designed for the placement of each tool are reasonably arranged, which not only meets the requirements for positioning related tools in the tool box, It is also properly ensured that each tool and the tool box do not produce impact and noise during the combined vehicle movement; the frame of the tool box is provided with an upper frame entit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com