A high-precision and high-efficiency monolithic two-degree-of-freedom microgripper for optical fiber assembly

A degree of freedom, micro-clamp technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of complex MEMS optical switches, serious assembly problems, component damage, etc., to achieve convenient and high-precision positioning, eliminating the assembly process, function Rich and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

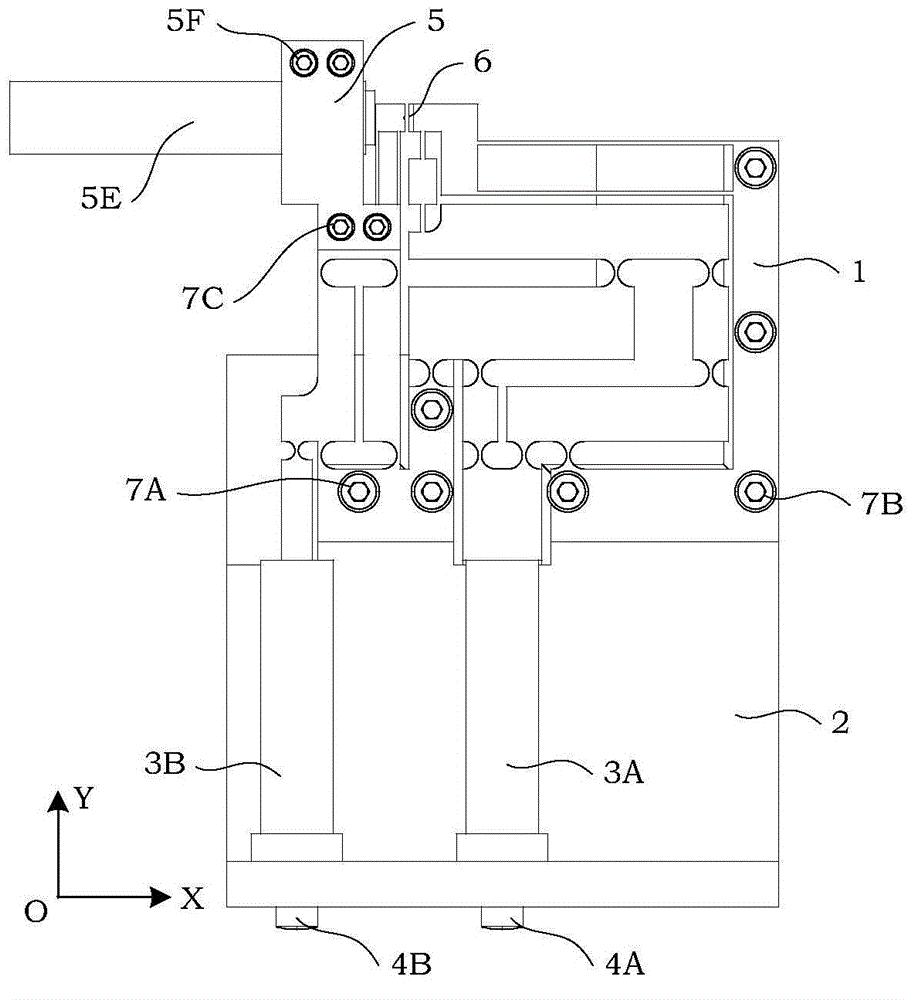

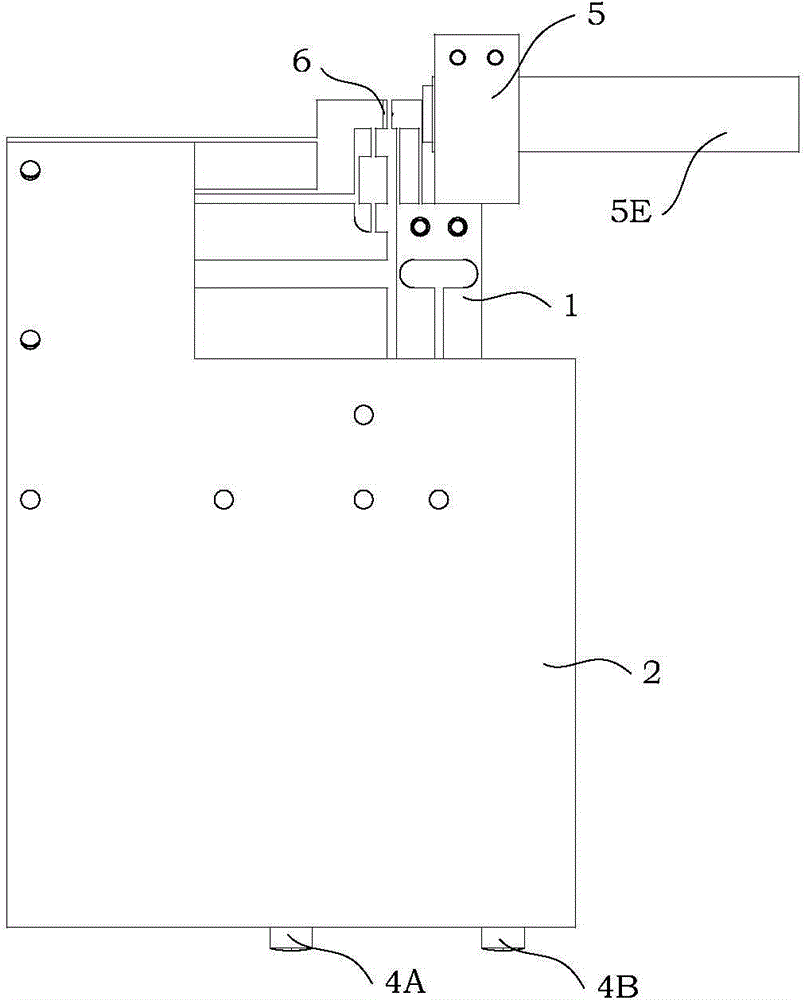

[0049] see figure 1 , Figure 1A , Figure 1B and Figure 1C As shown, a high-precision and high-efficiency monolithic two-degree-of-freedom micro gripper designed by the present invention for optical fiber assembly includes a capacitive sensor 5A, a piezoelectric ceramic driver 3A , B piezoelectric ceramic driver 3B, motion transmission mechanism 1, base 2, sensor mount 5, glass patch 6, pre-tightening bolts and fixing bolts.

[0050] Piezo driver

[0051] see figure 1 , Figure 1B and Figure 1C As shown, the A piezoelectric ceramic driver 3A is installed between the first input board 1A of the motion transmission mechanism 1 and the second panel 2B of the base 2, and the A piezoelectric ceramic driver 3A and the second panel 2B of the base 2 A B block 3D is placed between them.

[0052] see figure 1 , Figure 1B and Figure 1C As shown, the B p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com