Spiral type spring vibration screening equipment

A vibratory screening and spiral technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low separation rate of circular screen holes, low material passing rate, rigid screen surface organization and structure, etc., to improve One pass rate, reduction of multiple vibrations, separation effect and flow stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

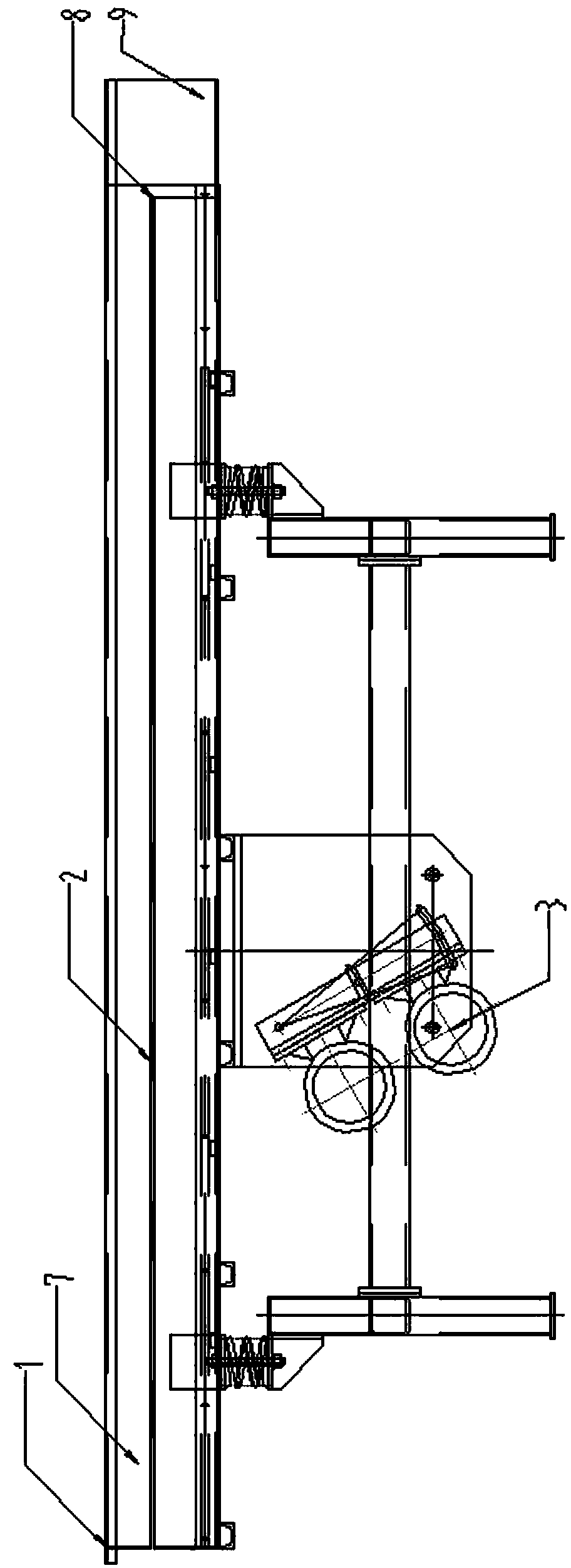

[0018] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings, wherein the "upper" and "lower" positional relationships described in this specification correspond to the upper and lower positional relationships shown in the accompanying drawings. The right side of the figure corresponds to the "front" side described in the description, and the left side in the drawings is the "rear" side described in the description.

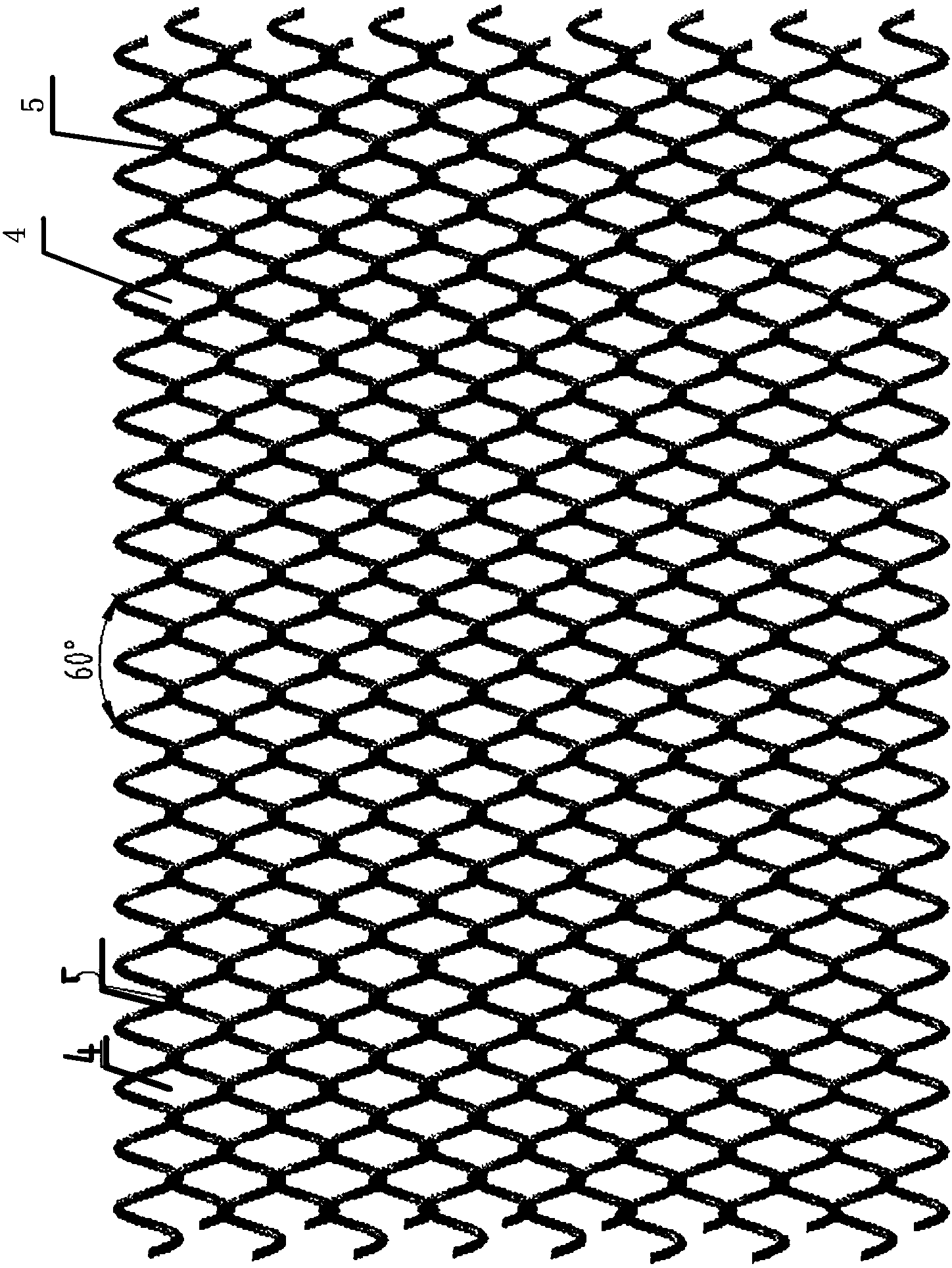

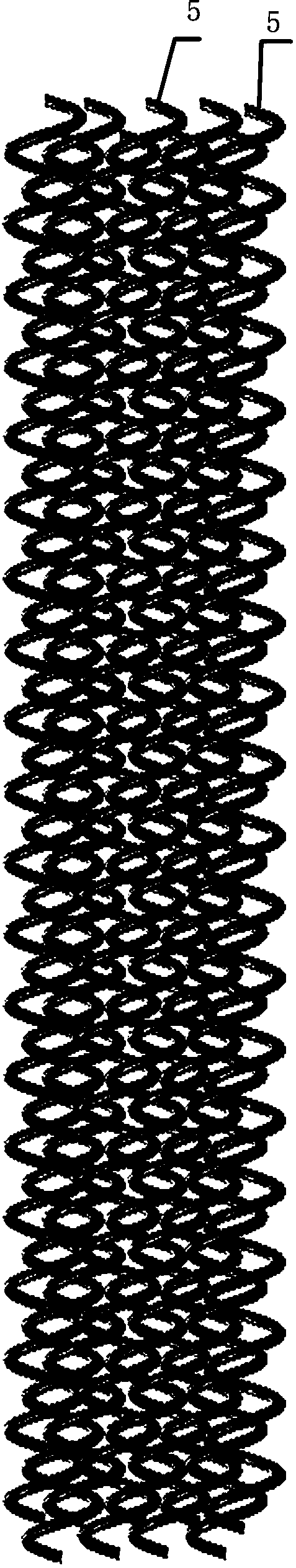

[0019] The present invention utilizes a sieve formed by spiral steel wires hooking each other to be used as a shredded tobacco sheet separation device. The spiral steel wire vibrating screen includes a spiral steel wire sieve for screening materials and has a certain vibration frequency The tank body, one or more layers of spiral steel wire screens are arranged in the middle of the tank body, and the spiral steel wire screens are two or more adjacent spiral steel wires 30 of different diameters. ° ~ 60° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com