Glass tube coating device

A technology of coating device and glass tube, which is applied to the device and coating of surface coating liquid, can solve the problems of inapplicability to large-scale automatic production, low degree of automation, and low efficiency, and achieve large-scale automatic production, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

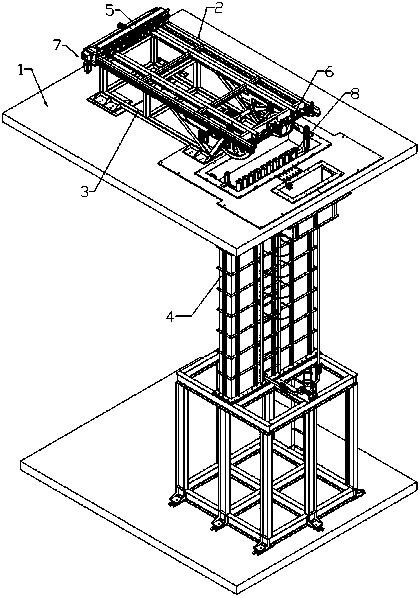

[0027] 参照附图,本发明提出一种玻璃管镀膜装置,包括机架1,所述机架1上设有:

[0028] 玻璃放置架2;

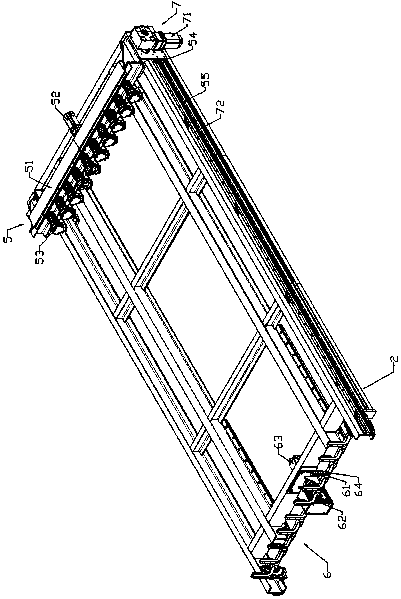

[0029] 锁紧机构5,可滑动的设置在玻璃放置架2上,将玻璃管牢固固定;

[0030] 翻转机构3,带动整个玻璃放置架2翻转90°;

[0031] 提升机构7,带动锁紧机构5在玻璃放置架2上移动;

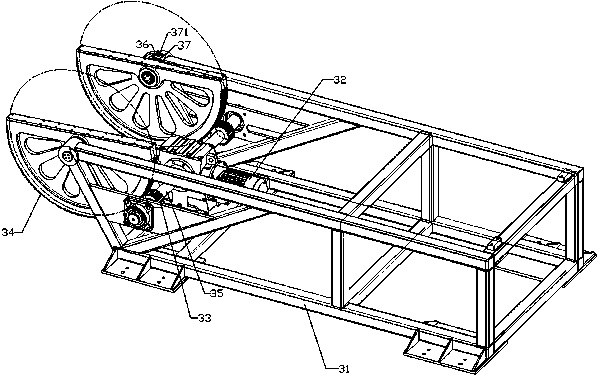

[0032] Specifically, the turning mechanism 3 includes a bracket 31, a turning motor 32, a driving gear 33 and a driven gear 34, the driving gear 33 and the driven gear 34 mesh with each other, the driven gear 34 is a semicircular gear, and the semicircular The center of circle of the shaped gear is hinged with the support 31, the right-angled side is fixed with the glass placement frame 2, the turning motor 32 is fixed on the support 31, the turning motor 32 drives the driving gear 33 to rotate, drives the driven gear 34 to rotate, and further drives the glass placement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com