Fully automatic five-in-one lithium battery forming machine

A lithium battery, fully automatic technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of single and incomplete equipment functions, low product quality, low work efficiency, etc., and achieve reduction The effect of operator demand, improvement of product quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

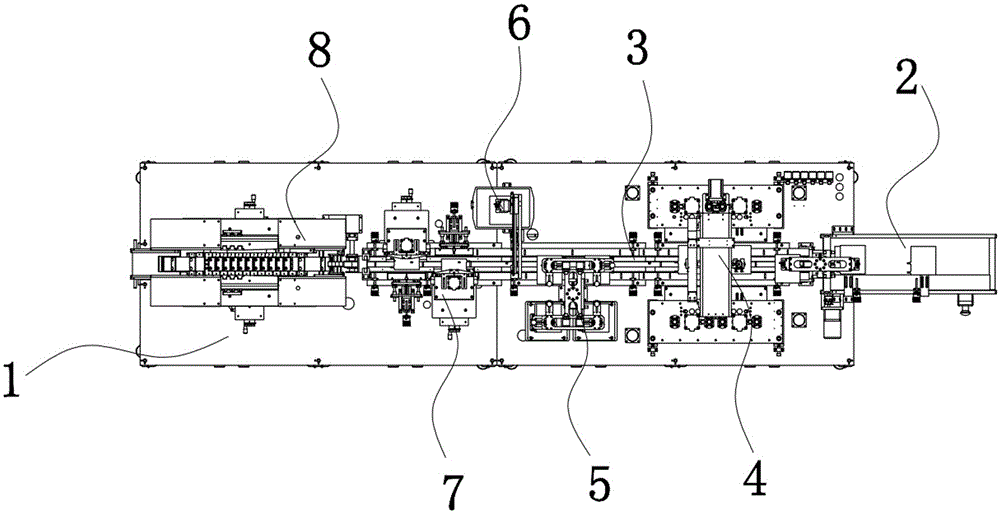

[0025] refer to figure 1 . The fully automatic five-in-one lithium battery forming machine includes a workbench 1 on which a feeding mechanism 2 is connected. There are fine packaging mechanism 4, testing mechanism 5, defective product rejecting mechanism 6, and single trimming mechanism 7. The end of the material conveying mechanism 3 is also connected with a folding and ironing mechanism 8. The support 1 is also composed of several columns. frame, on which the control system is also connected.

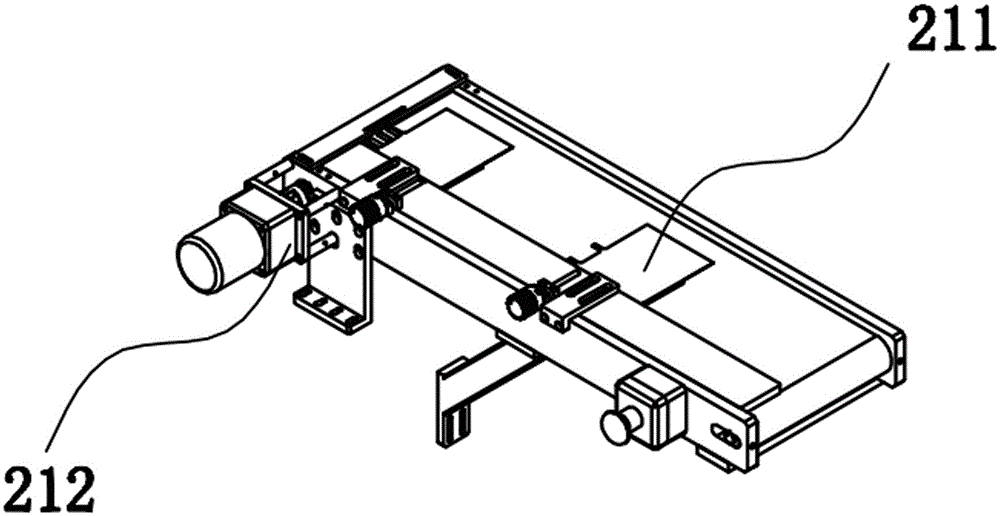

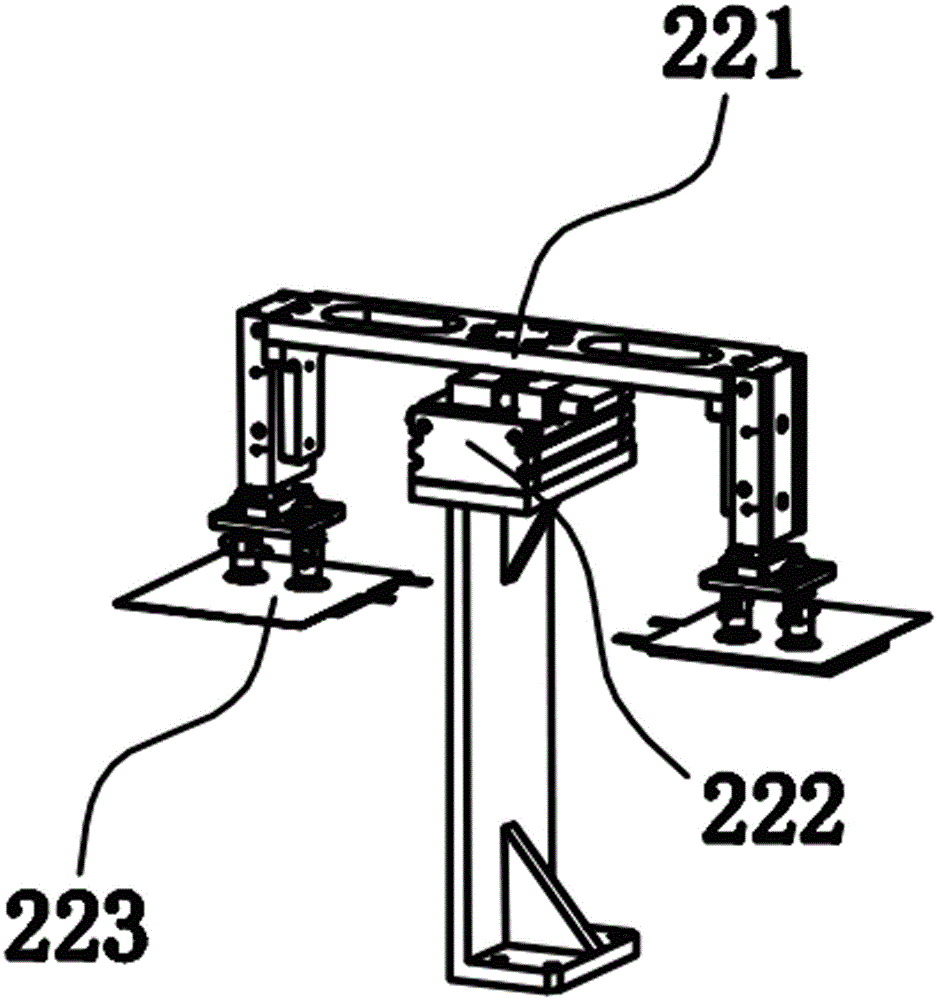

[0026] Such as figure 2 As shown, the feeding mechanism 2 includes a feeding pull belt, the charging pull belt is provided with a battery positioning plate 211, and one end of the feeding pulling belt is connected to a variable speed motor 212 to drive the feeding pulling belt to rotate. The end of the above-mentioned feeding drawstring is also provided with a feeding manipulator; image 3 As shown, the feeding manipulator is driven by the driving device 222 to swing the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com