Automatic Plastic Mixer

A mixer and fully automatic technology, applied in the field of fully automatic plastic mixers, can solve the problems that the mixture of plastic pellets cannot be mixed evenly, the mixed plastic pellets are layered up and down, and there are hidden safety hazards for the staff, so as to achieve simple structure and low manufacturing cost. Low, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

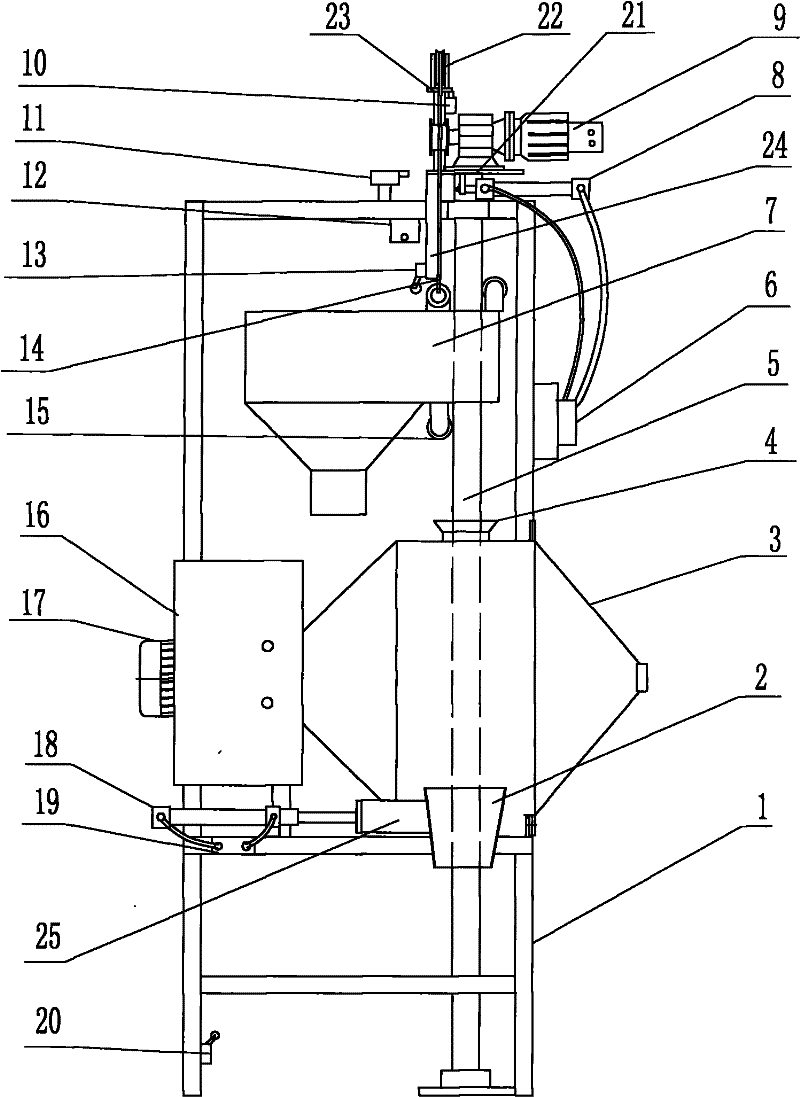

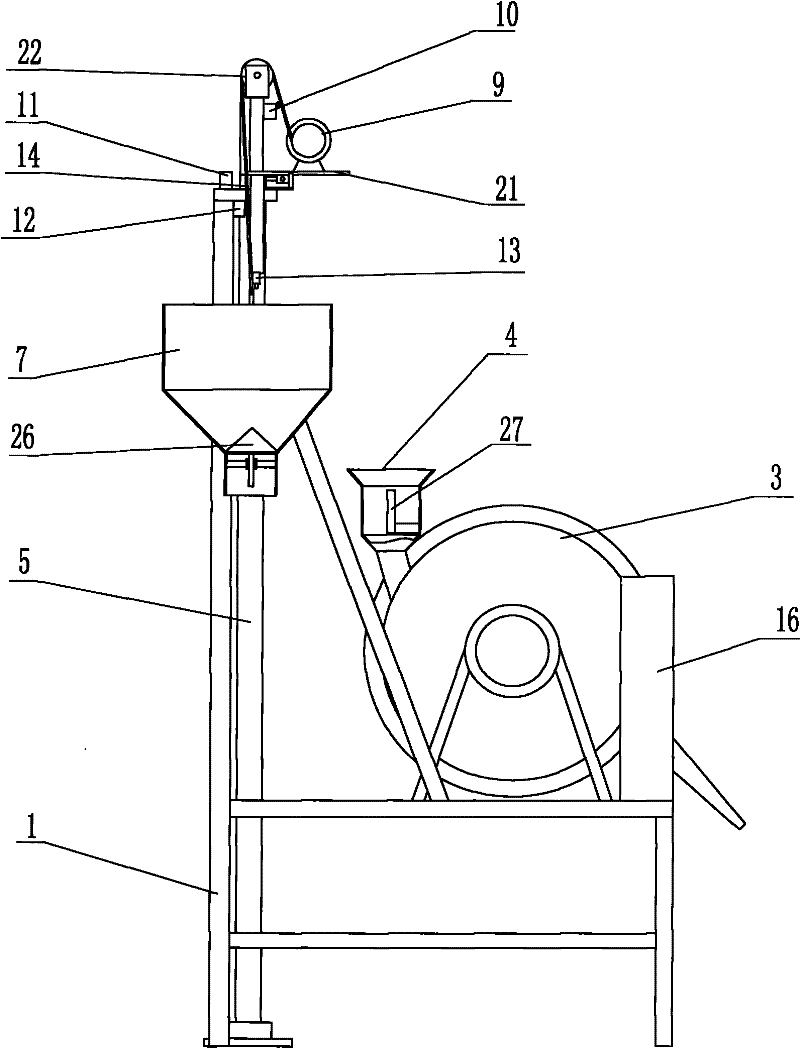

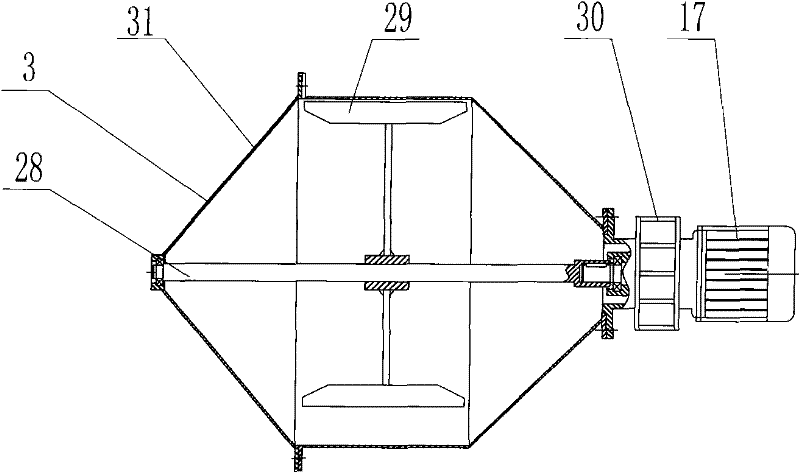

[0025] by attached figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of full-automatic plastic mixing machine, it comprises frame 1 lower platform fixed-mounted stirring device 3, electric control cabinet 16, pneumatic solenoid valve I19 and cylinder I18, pneumatic solenoid valve I19 connects cylinder I18 through air pipe, frame 1 Pneumatic solenoid valve II6 is installed on the right vertical girder, and pneumatic solenoid valve II6 is connected to cylinder II8 through the trachea, cylinder II8, right stroke switch 11 and left stroke switch 12 are installed on the upper beam, and floor stroke switch 20 is installed on the left bottom of frame 1; The lower end of the slide bar 5 is fixed on the foundation through the bearing seat, and the upper part is connected to the upper beam of the frame 1 through the bearing seat. Two rollers 15 are installed on the feeding hopper 7 to be flexibly connected with the rotating slide bar 5. The feeding hopper 7 is wound around by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com