Four-link extended leveling control system

A control system, four-link technology, applied in attitude control and other directions, can solve problems such as reducing service life, scratching and collision, affecting appearance, etc., to achieve the effect of prolonging service life, increasing overturning moment, and stable and reliable control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

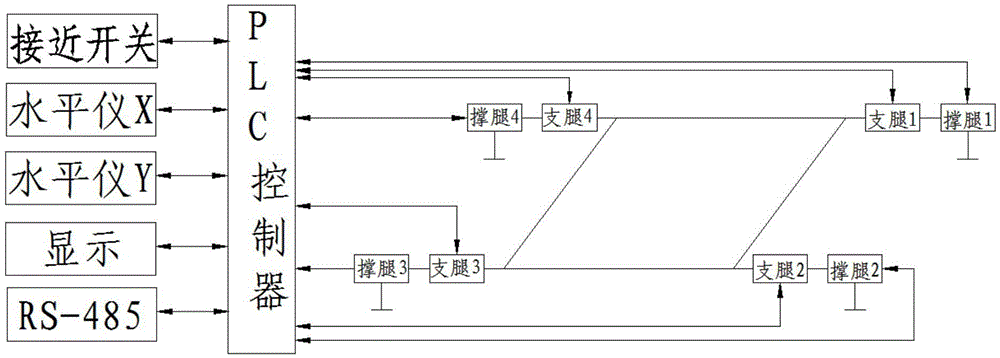

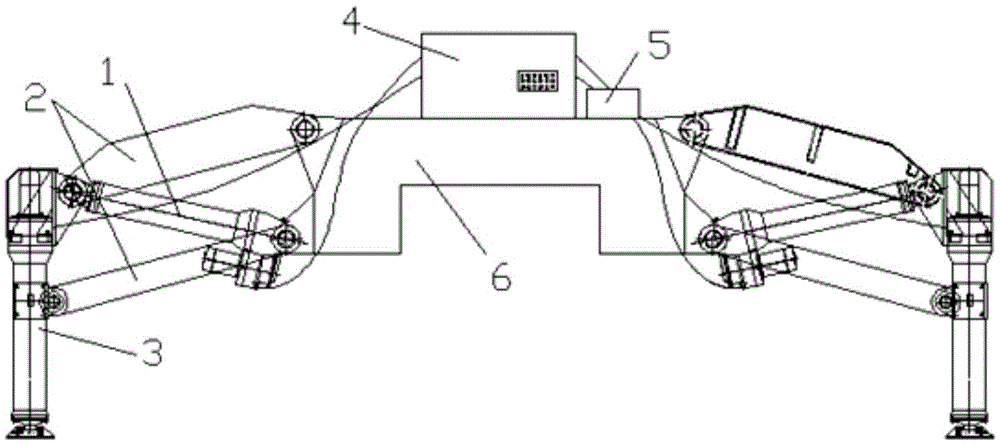

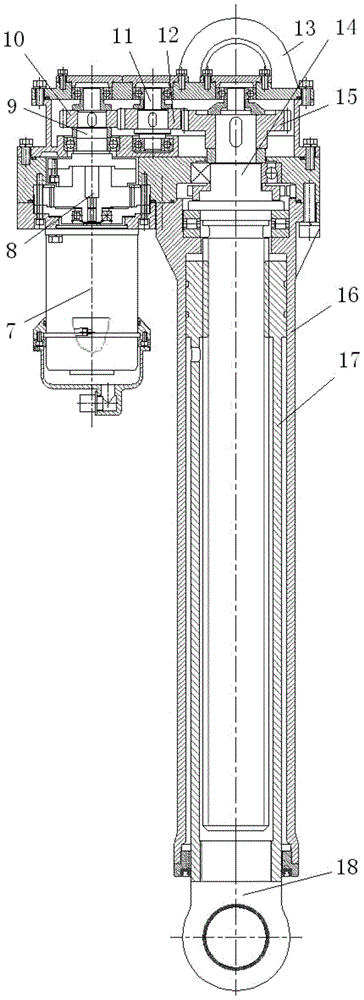

[0022] Such as Figure 1~4 As shown, the four-link extended leveling control system includes a working platform 6, four sets of legs 1 and four sets of legs 3, and each set of legs 3 connects with the working platform through two extension arms 2 and a set of legs 1. 6 are connected, and the supporting legs 1, 3 and the working platform 6 constitute a parallel four-bar linkage mechanism. The top surface of the working platform 6 is provided with a level sensor 5, a proximity switch and a control box 4, and the control box 4 is provided with A PLC controller connected to the level sensor 5 and the proximity switch, a display output device connected to the PLC controller and an RS-485 communication cable are provided on the control box, and motors are arranged in the legs 1 and 3. The motor is connected to the PLC controller through a cable, and the PLC controller controls the expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com