Construction method for super vacuum dewatering well and well tube structure used in construction method

A construction method and technology of precipitation wells, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of reducing precipitation effect, vacuum degree attenuation, and unsatisfactory use and effect of precipitation technology, so as to reduce labor intensity , avoid vacuum degree attenuation, and improve the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

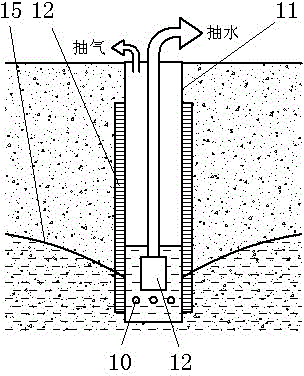

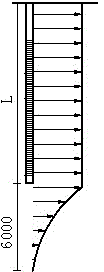

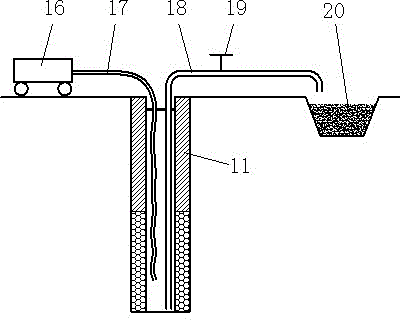

[0028] During specific construction, such as image 3 As shown, vacuum pump 16 and water pump 13 are used to extract the air and groundwater in the well pipe 11 at the same time, so that the inside of the well pipe 11 is kept sealed to form a stable and continuous negative pressure of high vacuum degree (greater than 0.08MPa) that is not affected by underground engineering construction. The vacuum makes the groundwater continuously and rapidly collect into the well under the action of negative pressure and vacuum. The principle of the present invention is as figure 1 As shown, due to being vacuumed in the well pipe 11, a higher negative pressure vacuum is always maintained at the bottom of the well pipe 11, so that the groundwater level line 15 is as figure 1 As shown in the curve, it accelerates the discharge of pore water in the soil. The present invention can be as follows before precipitation figure 2 The negative pressure shown in the depth range of L below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com