Connecting structure and connecting method for expansion joint water-stop belt of hydraulic concrete member

A technology of hydraulic concrete and connection method, which is applied in water conservancy projects, sea area projects, construction, etc., can solve the problems of high material and labor costs, time-consuming and labor-intensive problems, increase the ability to adapt to changes in joints, reduce stress concentration, and improve The effect of water pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

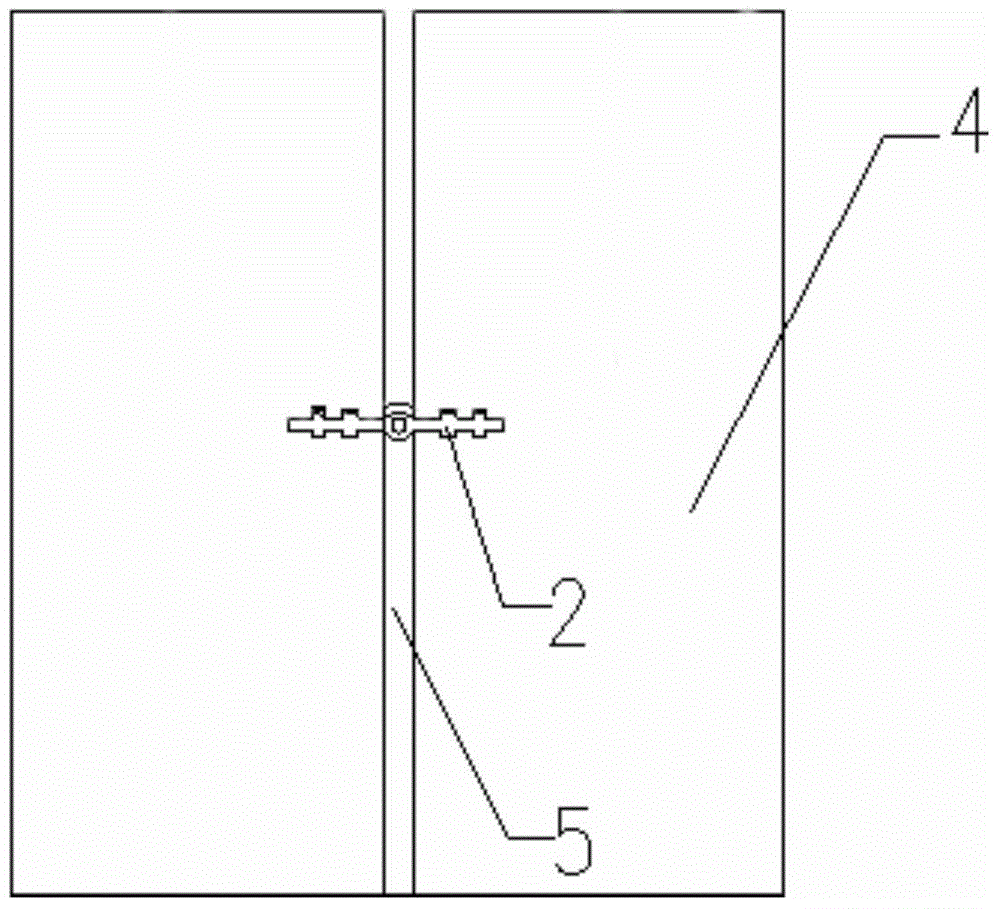

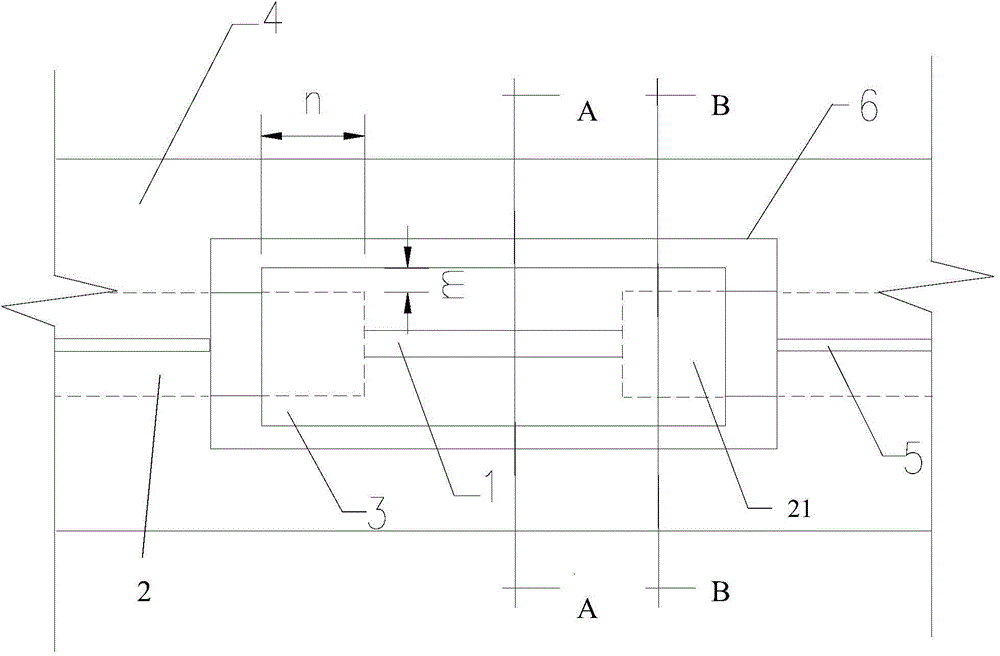

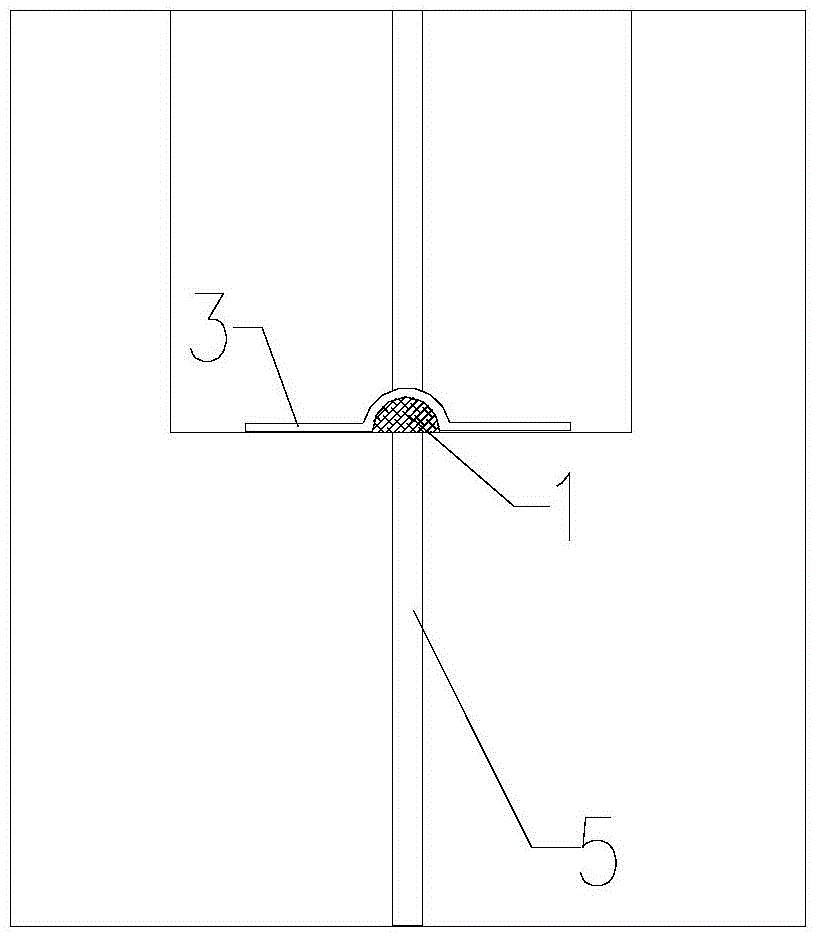

[0042] like Figure 2-Figure 4 As shown, when the water stop 2 pre-buried in the concrete on both sides of the expansion joint 5 in the hydraulic concrete member 4 is partially damaged, the concrete from the damaged part to the outer surface is chiseled first to form a rectangular groove 6, so that the stop The end 21 of the water belt 2 is exposed (or by cutting off the damaged part to form a relatively neat end 21 on both sides, which is a well-known method here, so it will not be described in detail), and at the same time pay attention to protect the remaining undamaged water stop 2, so as to avoid Damaged by concrete ballast. The expansion joint 5 between the ends 21 of the two waterstops 2 is filled with a sealing filling layer 1 composed of a flexible caulking material (see figure 2 and image 3 ), wherein the height of the sealing filling layer 1 may slightly protrude from the groove surfaces on both sides of the expansion joint 5 , and it is preferable to close the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com