Improved double-sided small circular knitting machine

A small circular knitting machine, an improved technology, is applied to circular knitting machines with separate action needles for weft knitting, textile and paper making, weft knitting, etc. Achieve the effect of improving performance and service life, improving weaving efficiency and quality, and improving weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

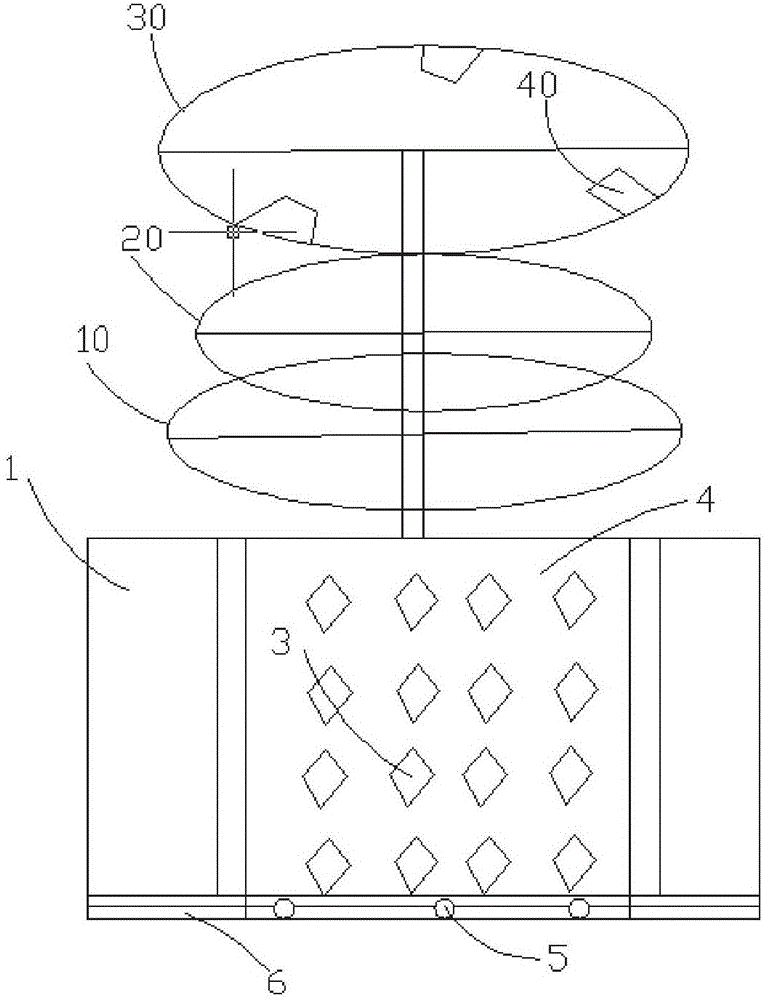

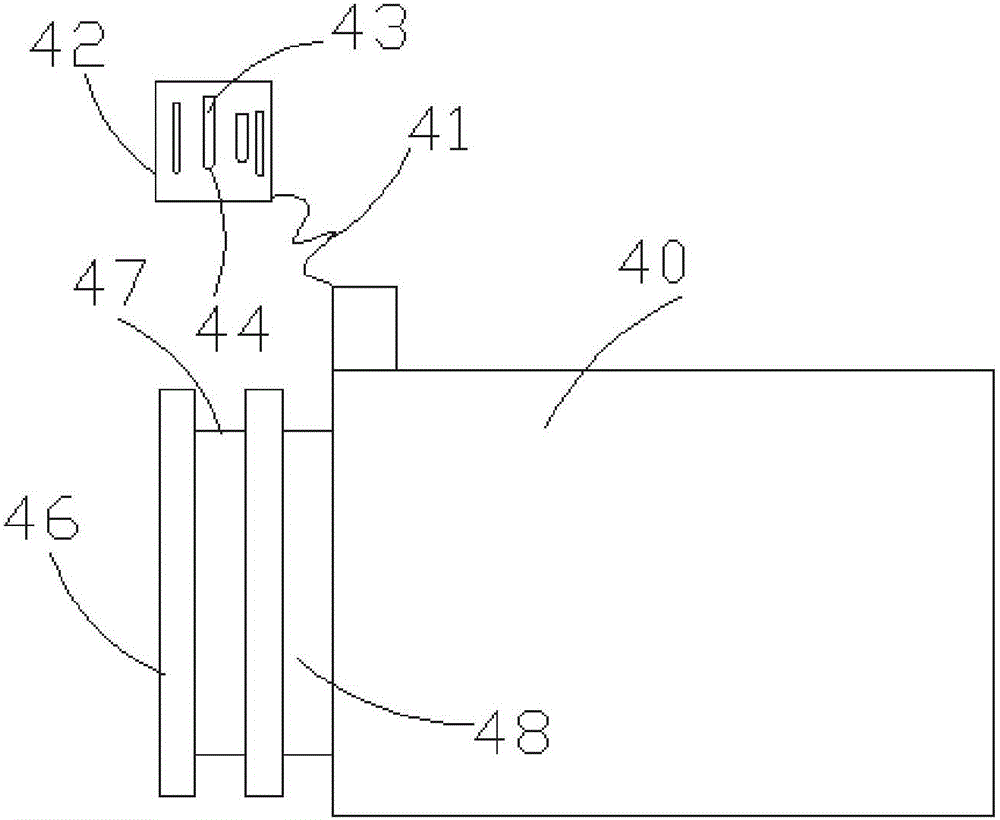

[0018] Such as figure 1 and figure 2 As shown, the present invention relates to an improved double-sided small circular knitting machine, which is characterized in that: it includes a frame, forming support columns 1 arranged in a triangular distribution at the bottom of the frame, and forming an installation reinforcement platform 2 between the support columns 1 , an arc-shaped safety guardrail 4 with ventilation holes 3 is arranged outside the support column 1, and a pulley 5 is provided at the bottom of the arc-shaped safety guardrail 4, and the pulley 5 is slidably arranged on a slide installed on the frame base. In the rail 6, the arc-shaped safety guardrail 4 can move left and right; the first installation circle 10 and the second installation circle 20 are formed on the frame, and the third installation circle 30 is formed on the second installation circle 20, wherein the first installation circle 30 The diameter of the three installation rings 30 is greater than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com