Colorless cementing material and preparation method thereof

A technology of cementing material and rubber oil, which is applied in the field of colorless cementing material and its preparation, can solve the problems of high cost of decolorization of petroleum asphalt, unfavorable promotion of colored cementing material, and uncontrollable quality of cementing material, and achieves excellent water damage resistance and is beneficial to Promotion, excellent effect of high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

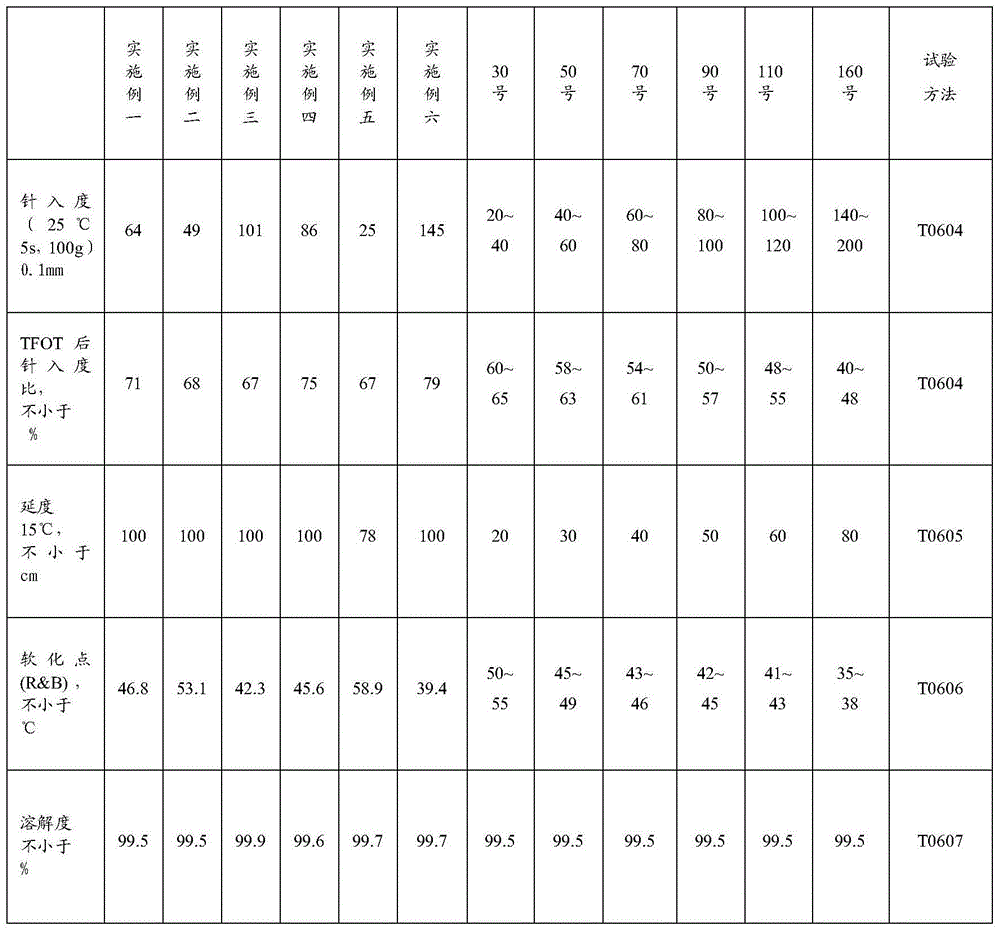

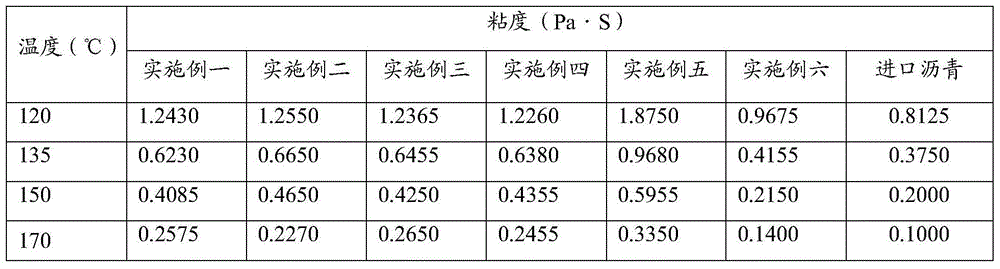

Examples

Embodiment 1

[0027] A kind of colorless binder, comprising 60kg rubber oil, 37kg carbon five petroleum resin, 3kg ethylene-vinyl acetate copolymer, is prepared according to the following steps:

[0028] Step 1: Inject 60kg of rubber oil into the reactor and heat up to 145°C-155°C;

[0029] Step 2, add 37kg of C5 petroleum resin to the reaction kettle with a screw conveyor, keep the temperature at 145°C-155°C, and stir until the reactants are completely melted;

[0030] Step 3: put 3kg of ethylene-vinyl acetate copolymer into the reaction kettle, stir, and swell for 5-7 hours; mix the components with each other to form a uniform mixture, and obtain the finished product of colorless cement.

[0031] When in use, the colorless cement is transported to the mixing building through the cleaned asphalt pump and pipeline to complete the production task.

Embodiment 2

[0033] A kind of colorless binder, comprising 58kg rubber oil, 39kg carbon five petroleum resin, 3kg ethylene-vinyl acetate copolymer, is prepared according to the following steps:

[0034] Step 1: Inject 58kg of rubber oil into the reactor and raise the temperature to 145°C-155°C;

[0035] Step 2, add 39kg of C5 petroleum resin to the reaction kettle with a screw conveyor, keep the temperature at 145°C-155°C, and stir until the reactants are completely melted;

[0036] Step 3: Put 3 kg of ethylene-vinyl acetate copolymer into the reaction kettle, stir, and swell for 5-7 hours; mix the components with each other to form a uniform mixture, and obtain a colorless cement product.

[0037] When in use, the colorless cement is transported to the mixing building through the cleaned asphalt pump and pipeline to complete the production task.

Embodiment 3

[0039] A kind of colorless binder, comprising 65kg rubber oil, 32kg carbon five petroleum resin, 3kg ethylene-vinyl acetate copolymer, is prepared according to the following steps:

[0040] Step 1: Inject 65kg of rubber oil into the reactor and heat up to 145°C-155°C;

[0041] Step 2, add 32kg of C5 petroleum resin to the reaction kettle with a screw conveyor, keep the temperature at 145°C-155°C, and stir until the reactants are completely melted;

[0042] Step 3: Put 3 kg of ethylene-vinyl acetate copolymer into the reaction kettle, stir, and swell for 5-7 hours; mix the components with each other to form a uniform mixture, and obtain a colorless cement product.

[0043] When in use, the colorless cement is transported to the mixing building through the cleaned asphalt pump and pipeline to complete the production task.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com