Anti-dust device for cement tank

A technology for dust-proof device and cement tank, which is applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems that the dust-absorbing device is not easy to clean, pollute the air and construction environment, and affect the dust-absorbing effect, and achieve simple structure and protection. Construction environment, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

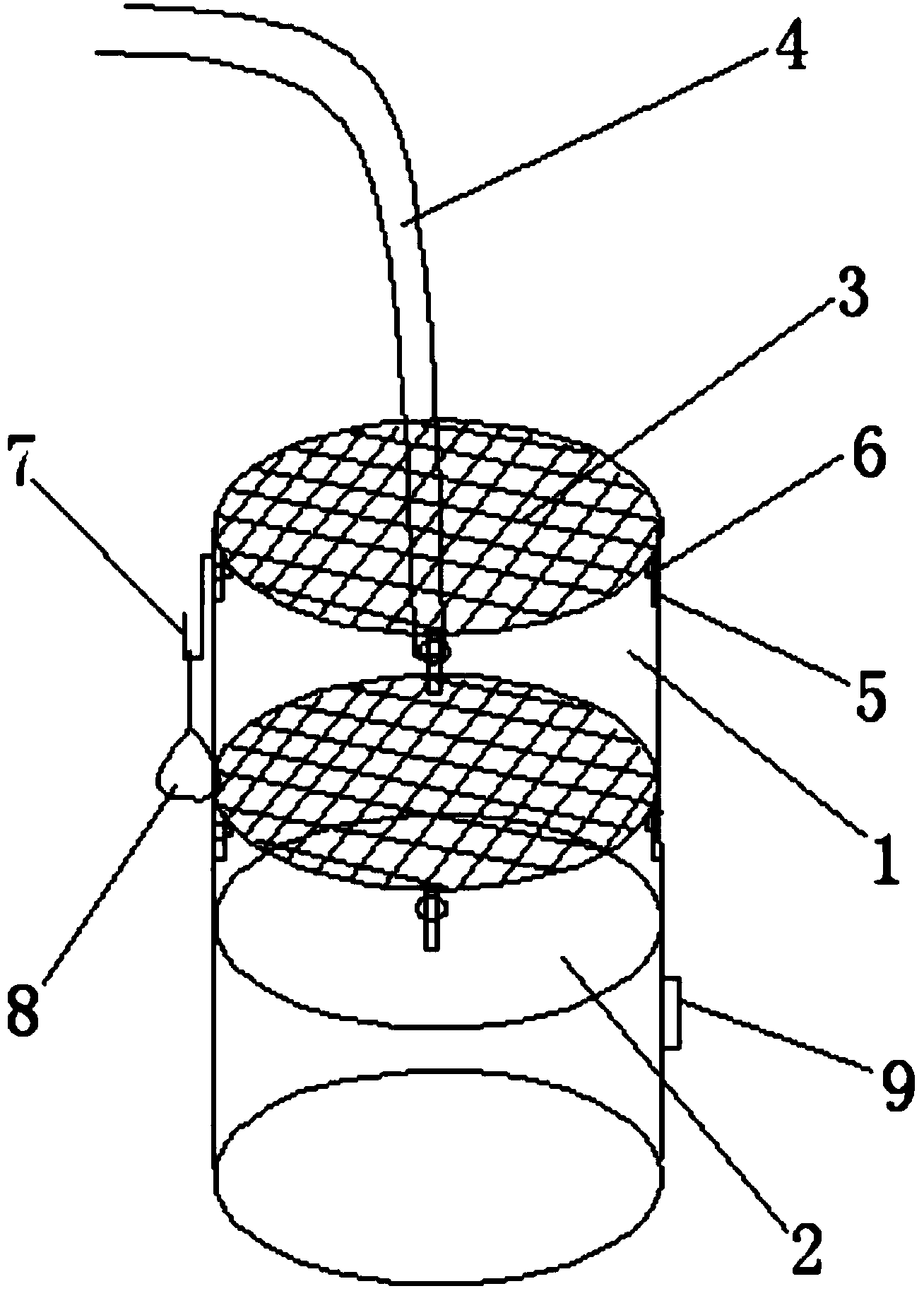

[0012] Such as figure 1 As shown, the present invention provides a cement tank dust-proof device, comprising a cylindrical barrel body, a circular dust-proof net is arranged above the water surface inside the barrel body, and there are two dust-proof nets, which are respectively arranged on the upper part of the barrel body and central. Four fixing pins are evenly and symmetrically distributed on the edge of the dust-proof net, and a fixing ring matched with the fixing pins is arranged inside the bucket body, and the dust-proof net and the bucket body are fixed to each other through the fixing pins and the fixing rings. A water outlet is arranged on the side of the lower part of the bucket body, and a water outlet cover is arranged on the water outlet. A hook is arranged on the upper side of the barrel, and a kettle is arranged on the hook. When the cement comes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com