Bookbinding Machine

A stapler, cutting and lifting technology, applied in binding and other directions, can solve the problems of damage energy, enlargement, etc., and achieve the effect of reliable binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

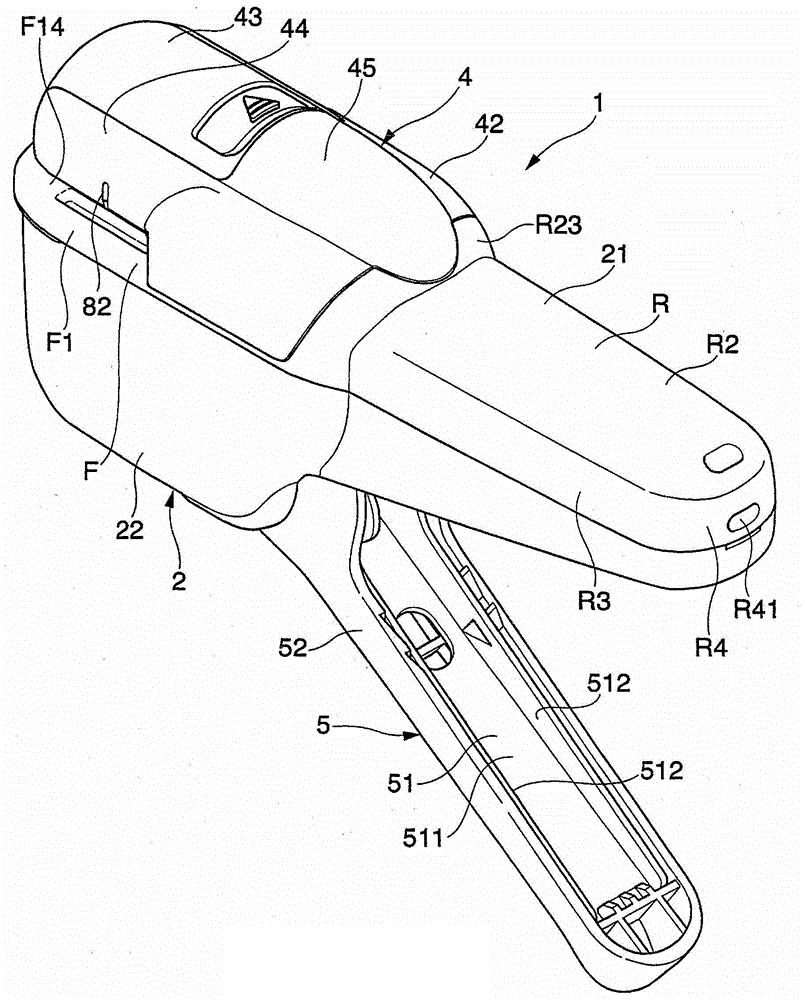

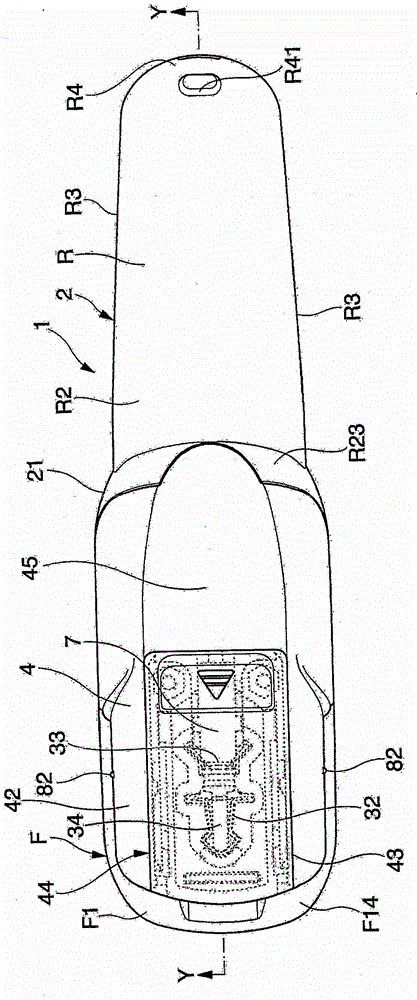

[0047] Refer to the side below Figure 1 to Figure 16 One embodiment of the present invention will be described.

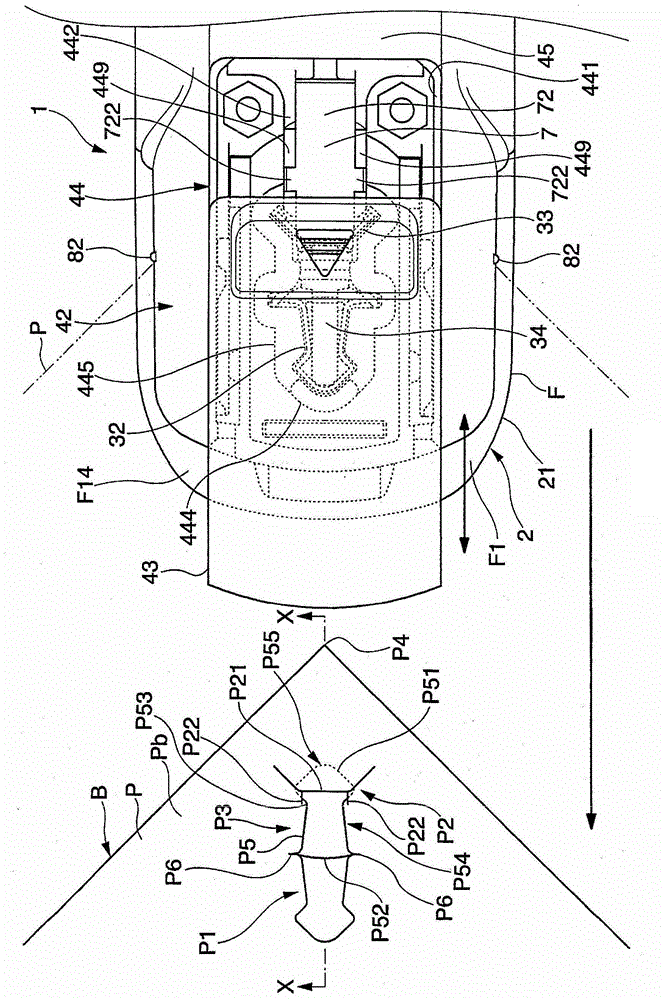

[0048] Such as Figure 1 to Figure 16As shown, the stapler 1 according to this embodiment can form a through hole P1 and a cut hole P2 on a plurality of sheets of paper P, and make the cut and raised piece P5 cut and pulled up from the through hole P1 pass through the cut hole. P2, the booklet B is produced by binding these sheets P to each other.

[0049] Such as image 3 as well as Figure 4 As shown, the above-mentioned booklet B is a bundle of a plurality of sheets P, and these sheets P are joined together at a joint portion P3 set at a corner P4. The joining portion P3 is composed of a through hole P1 formed on each paper P by a perforating knife 32 inserted from the side Pa of the paper P, and a pull-up cut hole P2 adjacent to the through hole P1. is formed on each of the above-mentioned paper sheets P; Then, the corners P4 of the plurality of sheets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com