Stapler

A stapler and staple technology, which is applied in the directions of bookbinding, staple staple tools, manufacturing tools, etc., to achieve the effects of improving appearance, ensuring safety, and excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, typical embodiments of the present invention will be described using the drawings.

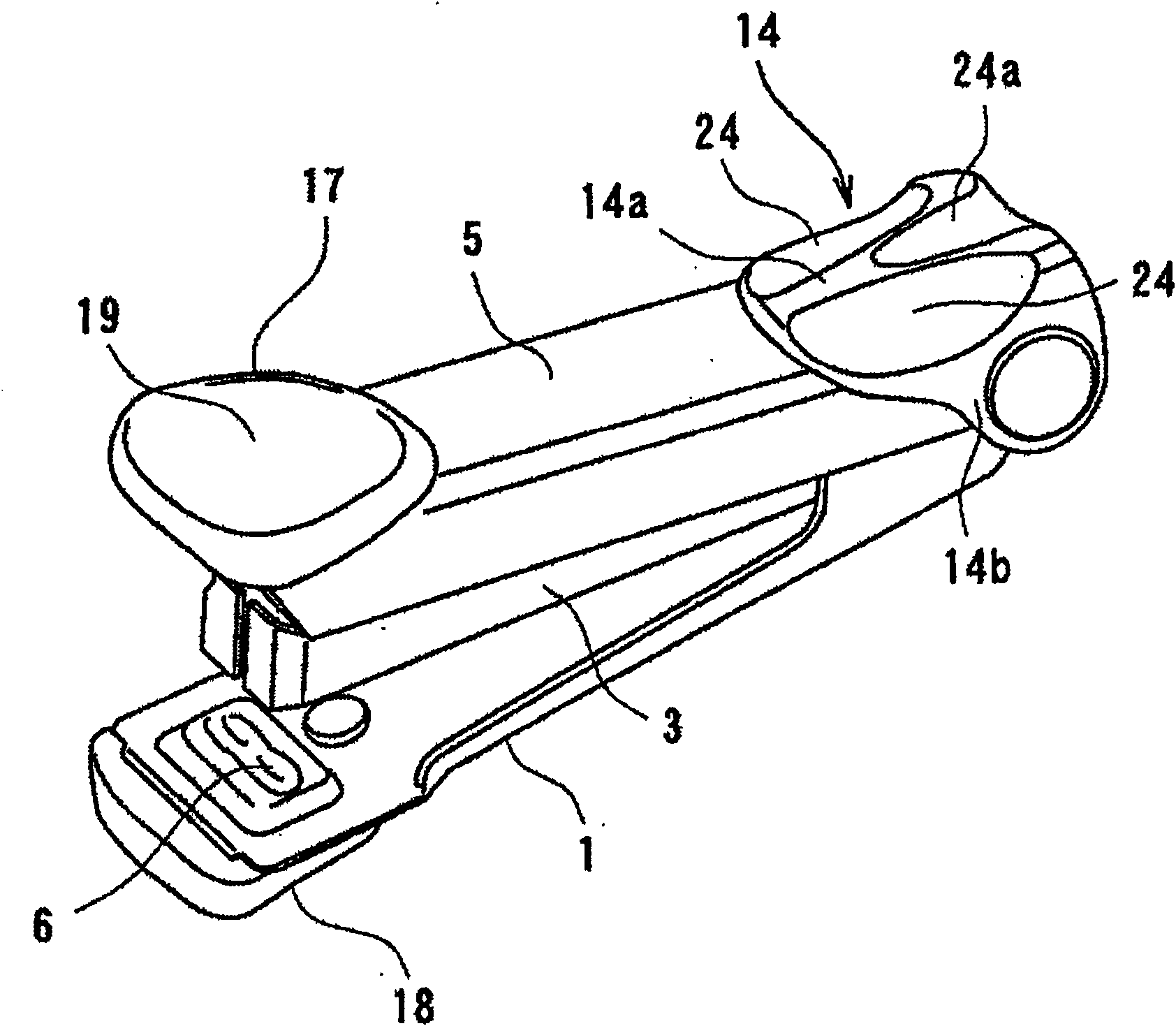

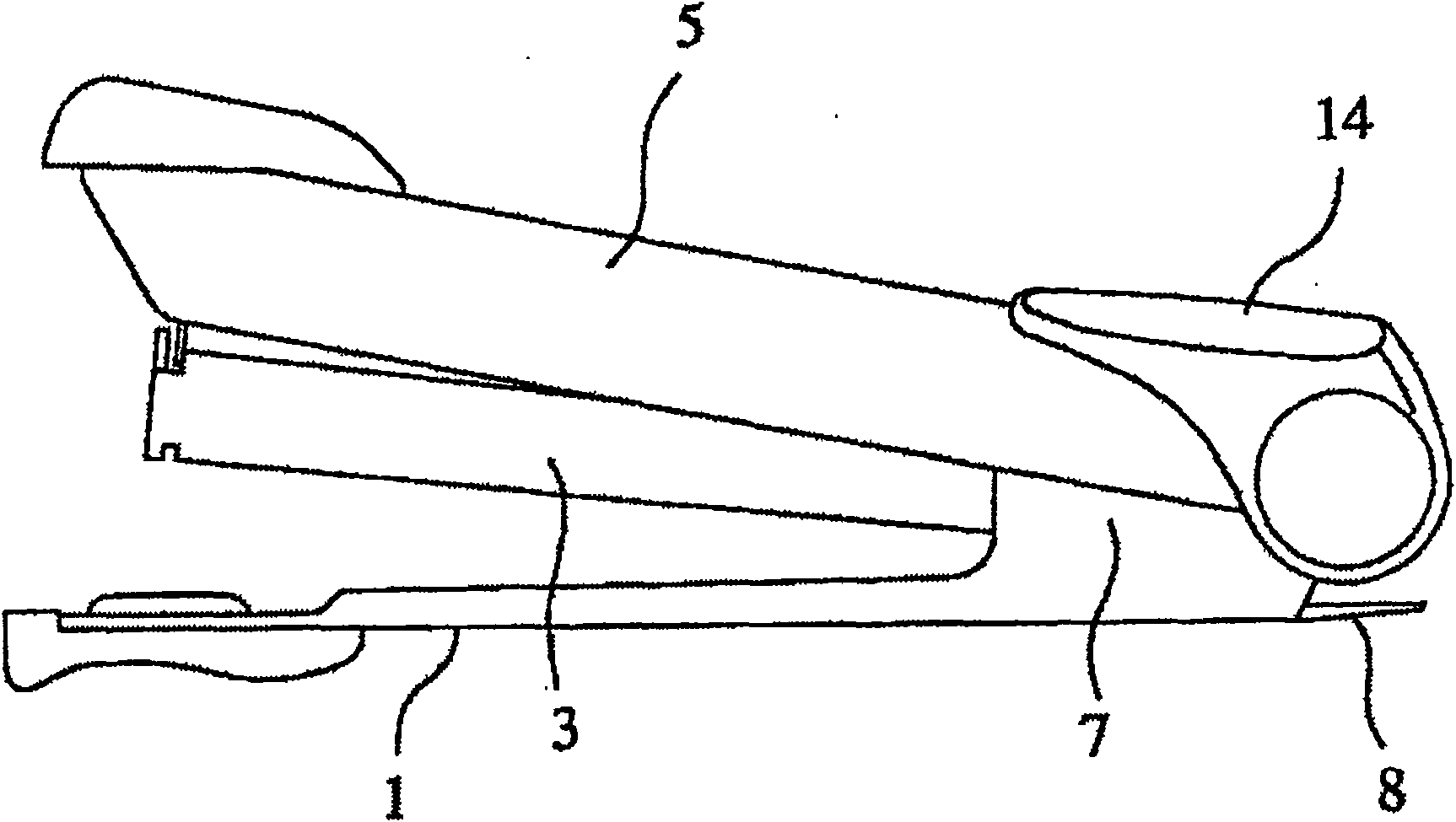

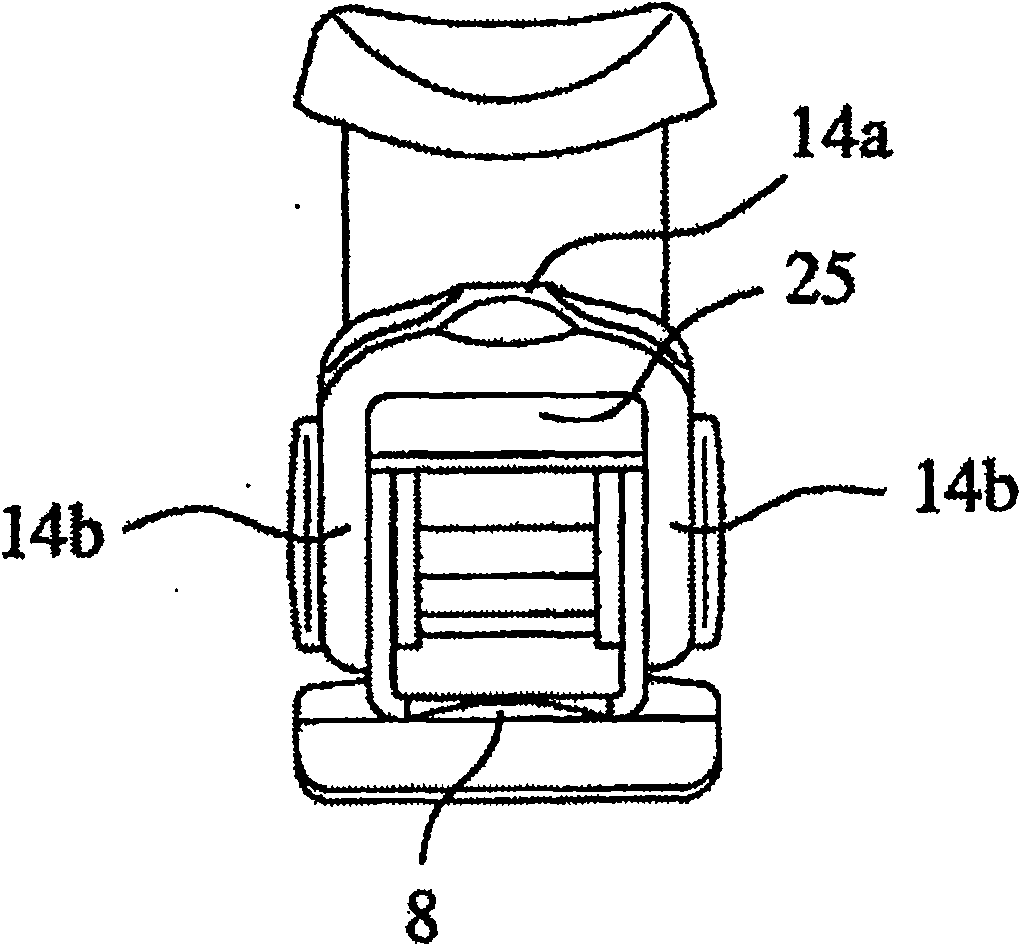

[0044] figure 1 It is the perspective view of the stapler of typical embodiment, and Fig. 2 (a) and Fig. 2 (b) are its side view and back view respectively, image 3 It is a sectional view showing the rough structure of the stapler. In this stapler, the nail box part 3 and the handle part 5 that accommodates a plurality of staples are rotatably supported by the support shaft 2 at the rear end of the base 1. The staples (not shown) in the box portion 3 face the driving plate 4 from which the staple paper is driven.

[0045] Clincher grooves 6 for bending legs of staples driven from the magazine unit 3 are formed at the front end of the base 1 . The support wall 7 is formed upright on the base. In addition, a thin plate-shaped staple remover 8 with a tapered front end protrudes from the rear end of the base 1 in order to remove the staples that bind the bound paper.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com