A manual noodle machine

A noodle machine, manual technology, applied in the direction of dough extruder, etc., can solve the problems of non-adjustable noodle hardness and laborious operation, and achieve the effect of simple structure, convenient installation, disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

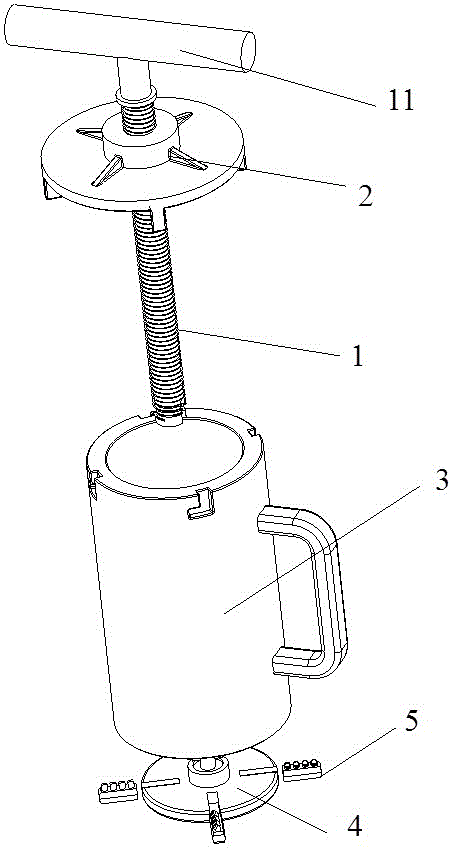

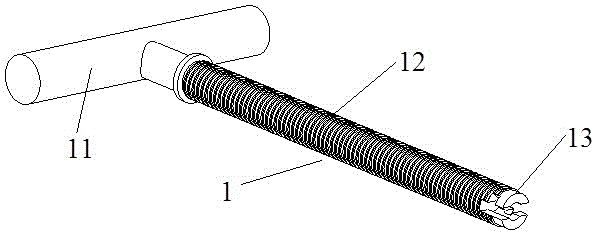

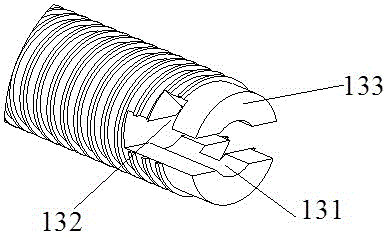

[0039] see figure 1 and Figure 8 , is the embodiment of a kind of manual noodle machine of the present invention, and it comprises screw mechanism 1, material barrel upper cover 2, material barrel 3 and cutter head mechanism, material barrel upper cover 2 is provided with threaded hole 22, and screw mechanism 1 passes threaded hole 22 is engaged with the cutterhead mechanism, and a square-tooth screw mechanism that transmits large torque can be selected. When the screw mechanism 1 works, the torque is transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com