Sealing device

A technology for sealing devices and holes, which is applied to the sealing of engines, engine components, machines/engines, etc., which can solve the problems of damaged sealing functions, the detachment of the sealing device 200, and the reduction of the force of fitting and fixing, so as to achieve simple structure, The effect of suppressing the separation of the sealing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

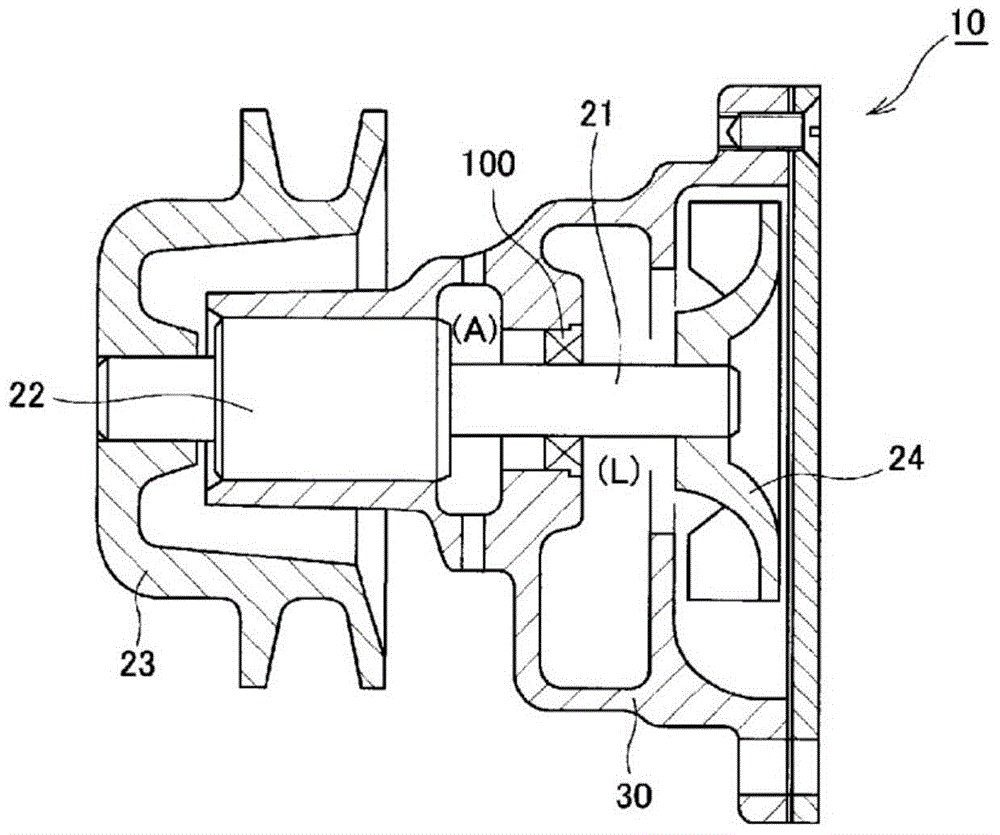

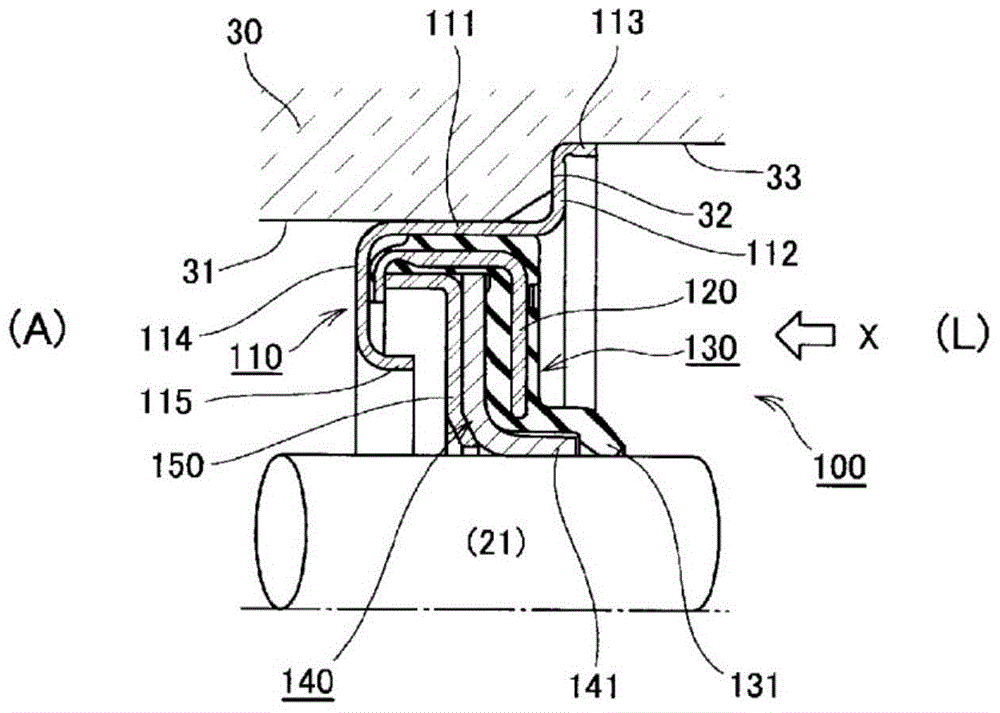

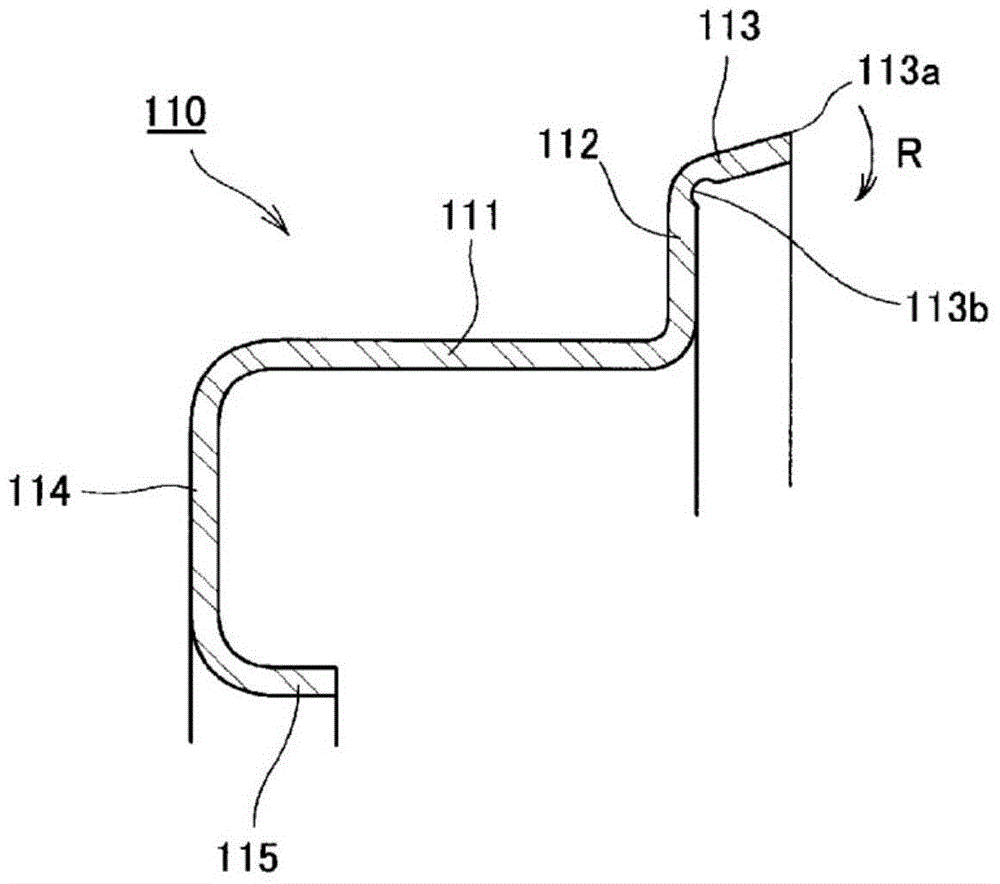

[0061] combine Figure 1 ~ Figure 4 The sealing device of Embodiment 1 of the present invention will be described.

[0062]

[0063] combine figure 1 An application example of the sealing device 100 according to the embodiment of the present invention will be described. figure 1 It is a schematic sectional view of the water pump 10 for an automobile. The water pump 10 includes a shaft 21 and a shaft housing 30 having a shaft hole through which the shaft 21 passes. A bearing 22 for smooth rotation of the rotating shaft 21 is installed on the rotating shaft 21 . A pulley 23 is attached to one end of the rotating shaft 21 to provide rotational driving force by rotating a belt (not shown), and an impeller 24 for pressure-feeding cooling water (LLC) is attached to the other end. The sealing device 100 of this embodiment is disposed in the annular gap between the shaft 21 and the shaft housing 30 to suppress leakage of cooling water to the outside (ie, the side (A) opposite ...

Embodiment 2

[0076] Figure 5 Example 2 of the present invention is shown. In this embodiment, a modified example of the case of the above-described first embodiment will be described. In the above-mentioned Embodiment 1, the claw protruding from the end of the flange portion of the housing has a ring shape. In the above-mentioned case where the claws are ring-shaped, the rigidity of the claws is high, so the wall thickness of the parts constituting the housing and the diameter of the claws will cause excessive force required to deform toward the inner peripheral surface, making installation Insertion force is too high when sealing the device. Thus, in the present embodiment, the claw portion is partially provided in the circumferential direction. The structures and functions other than the casing are the same as those in Embodiment 1, so the same symbols are added to the parts with the same structure, and their descriptions are omitted.

[0077] The metal casing (bush) 160 of this emb...

Embodiment 3

[0084] Figure 6 Example 3 of the present invention is shown. Depending on the relationship between the diameter of the rotating shaft and the diameter of the shaft hole of the shaft housing, there are situations where the annular gap to be sealed by the sealing device is very large. Therefore, in the sealing device of this embodiment, by providing the housing with an S-shaped section, it has elasticity in the radial direction, and even if it is used in a large annular gap, it will not deteriorate the mountability, and the sealing can be fully exerted. sex. The structure other than the housing is basically the same as that shown in the first embodiment above, so it will be briefly described.

[0085] In the sealing device 100 of the present embodiment, as in the first embodiment described above, a metal housing (bushing) 170, a metal ring 120a, a first sealing member 130a, a second sealing member 140a, and a backup ring 150a are provided. In the case of this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com