Magnetic loop of high-speed motor of electric vehicle

A technology of high-speed motors and electric vehicles, applied in the field of electric vehicles, can solve the problems of troublesome maintenance of Hall, easy burnout of Hall, high repair rate, etc., and achieve the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

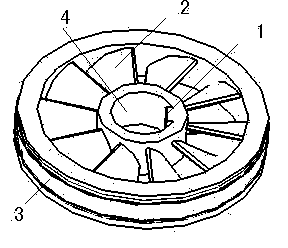

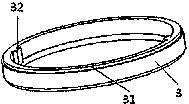

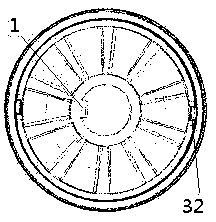

[0016] The invention discloses a magnetic ring of a high-speed motor of an electric vehicle, such as figure 1 , 2 As shown in , 3, the magnetic ring of the high-speed motor of the electric vehicle is formed by injection molding of the magnetic ring 3 sleeves on the mold. The hole 4 is matched with the motor shaft, the salient pole 1 and the motor shaft slit form a limit, the magnetic ring 3 is located on the radially outer peripheral wall of the magnetic ring, and the radially outer two end surfaces of the magnetic ring 3 are provided with steps 31, which are covered with plastic As a vertical limit, the inner diameter of the magnetic ring 3 is formed with at least one salient pole 32 acting on the circumferential limit of the magnetic ring 3. The salient pole 32 and the inner hole 4 salient poles 1 are formed with the center of the circle as the center. The ten-degree connection is aligned, and a fan 2 is made at the connection between the inner hole 4 and the outer ring. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com