A High Performance Combined Rectangular Waveguide

A rectangular waveguide and combined technology, which is applied in the field of high-performance combined rectangular waveguides, can solve the problems that the rectangular waveguide cavity cannot work normally, the influence degree is increased, etc., so as to improve the microwave transmission characteristics, good contact state, and solve the problem of microwave leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

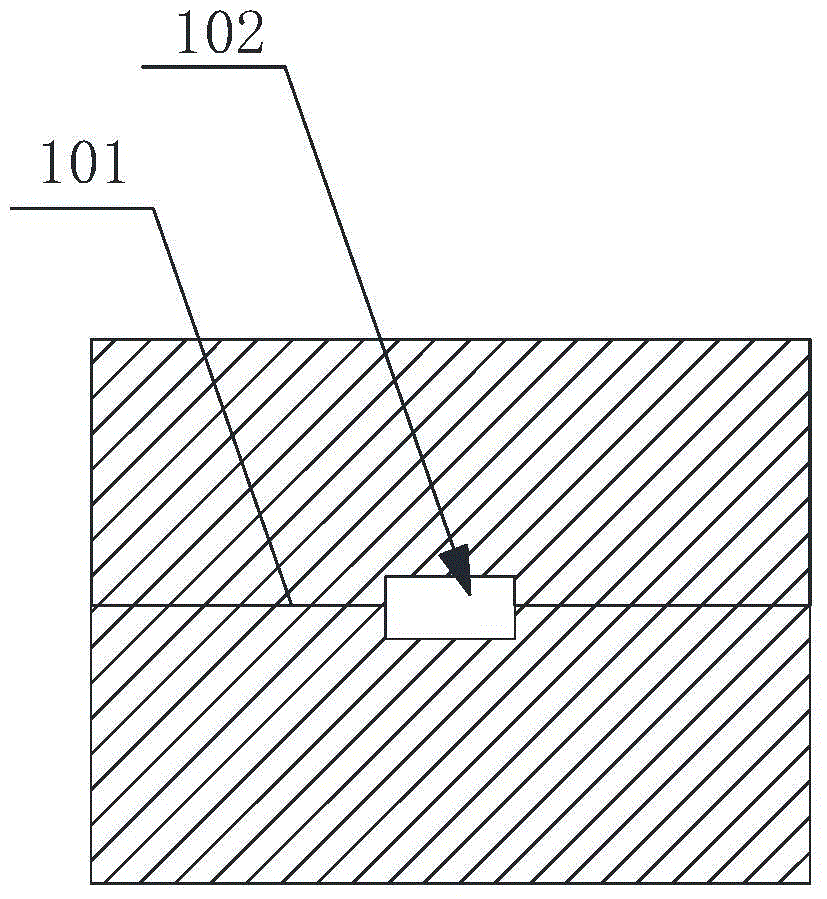

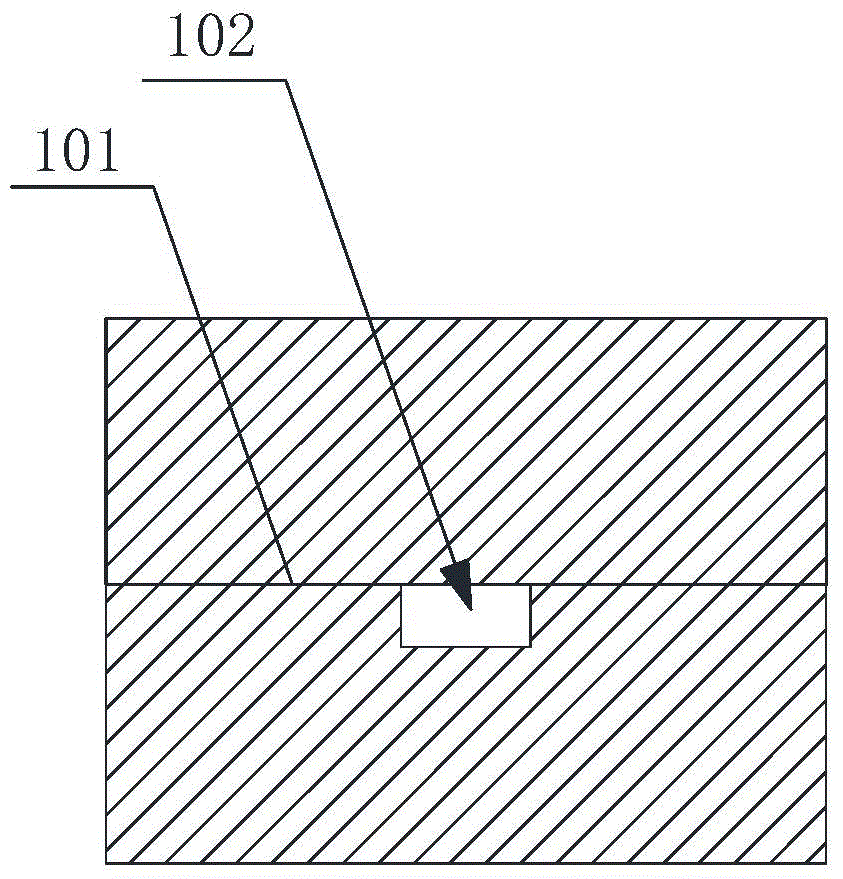

[0029] combine Figure 6 to Figure 11 As shown, a high-performance combined rectangular waveguide includes two waveguide cavity components 201 and 202, and a rectangular waveguide cavity 203 extending along the transmission direction of microwave signals is provided at the connection of the waveguide cavity components. Viewed along the extending direction of the rectangular waveguide cavity 203, a first contact portion 204 and a second contact portion 205 are respectively provided at the junction located on both sides of the rectangular waveguide cavity 203, next to the rectangular waveguide cavity, and the first contact portion 204 and the second contact portion The extending direction of the contact portion 205 is the same as that of the rectangular waveguide cavity 203 .

[0030] There is one first contact part 204 , which is arranged on one of the waveguide cavity components 201 or 202 . A first contact surface is formed between the first contact portion 204 and another w...

Embodiment 2

[0039] Except that the following technical features are slightly different from some of the technical features in Embodiment 1, the rest of the technical features not mentioned in Embodiment 2 are completely the same as those in Embodiment 1, and will not be described in detail here.

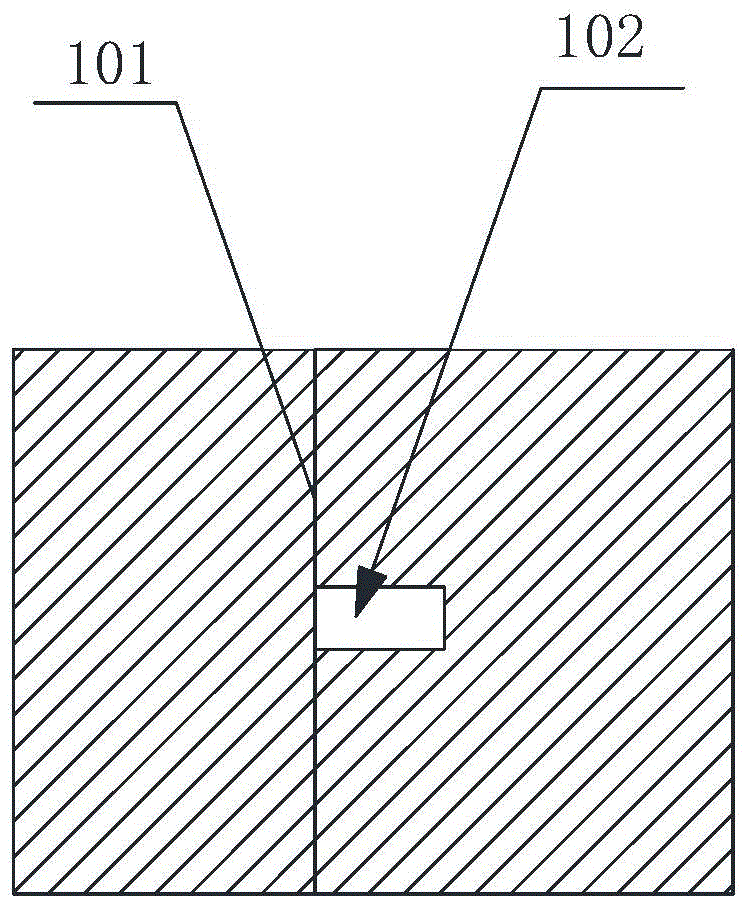

[0040] Such as Figures 12 to 15 As shown, there are two first contact portions 204 , which are respectively arranged on the two waveguide cavity assemblies 201 and 202 , and a first contact surface is formed between the two first contact portions 204 .

[0041] There are two second contact portions 205 , which are respectively arranged on the two waveguide cavity assemblies 201 and 202 . A second contact surface is formed between the two second contact portions 205 .

[0042] The first contact portion 204 and the second contact portion 205 have the same thickness. The sum of the thicknesses of the two first contact portions 204 should be kept between 0.3mm˜1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com