A tool for installing the bushing of vacuum circuit breaker

A vacuum circuit breaker and bushing technology, which is applied to circuits, electrical components, electric switches, etc., can solve problems such as time-consuming, vacuum circuit breakers cannot meet insulation requirements, and high labor costs, and achieve enhanced stability and reliability. , meet the high protection level and improve the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

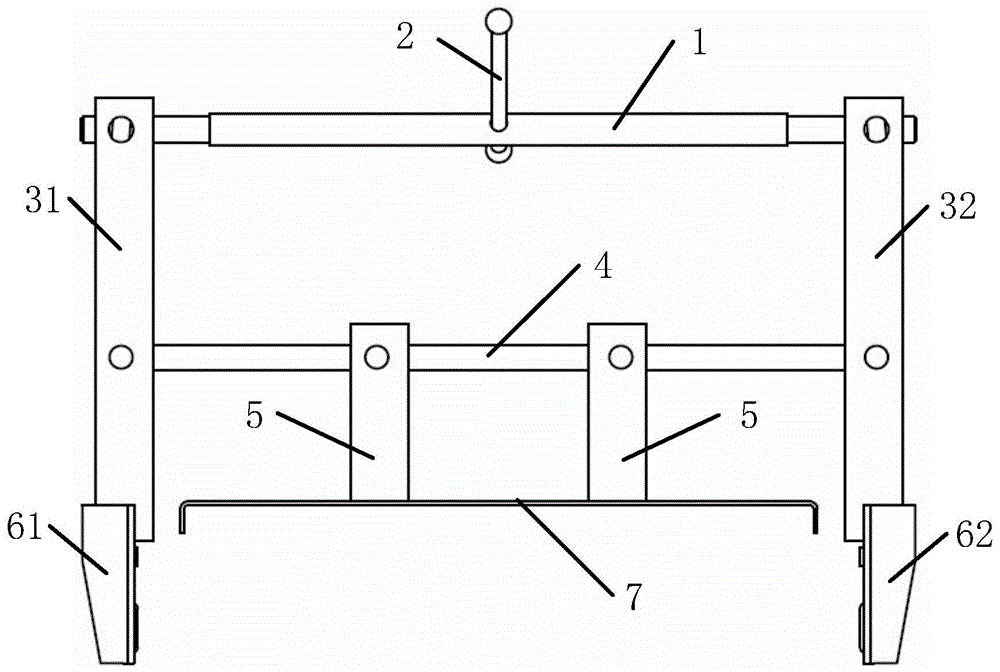

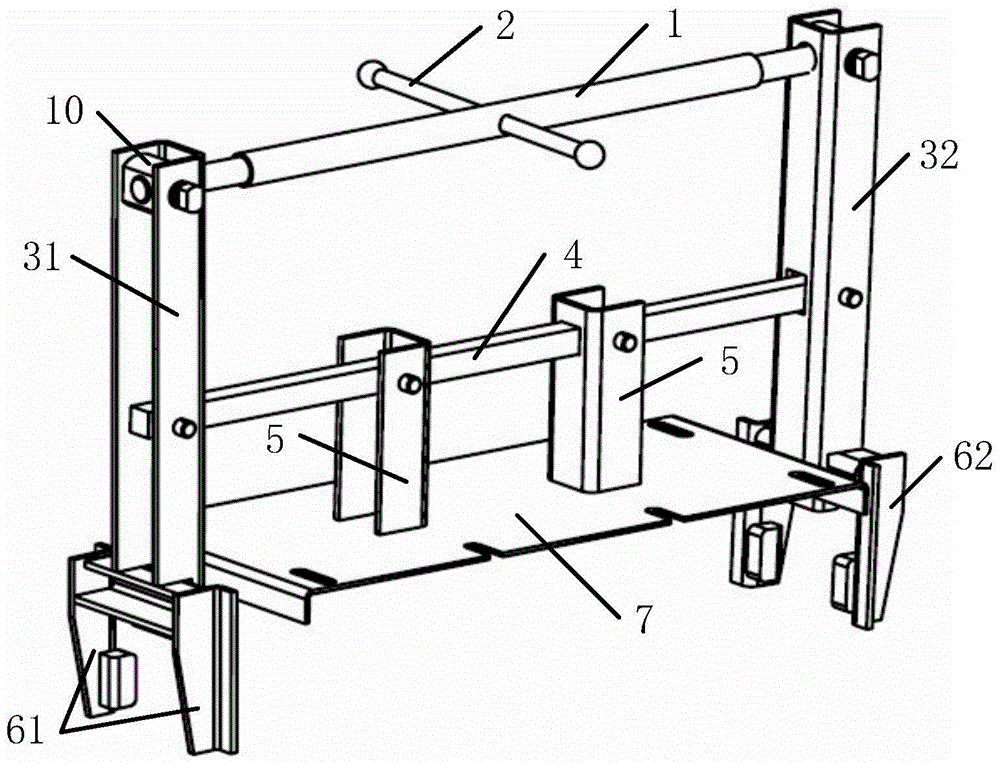

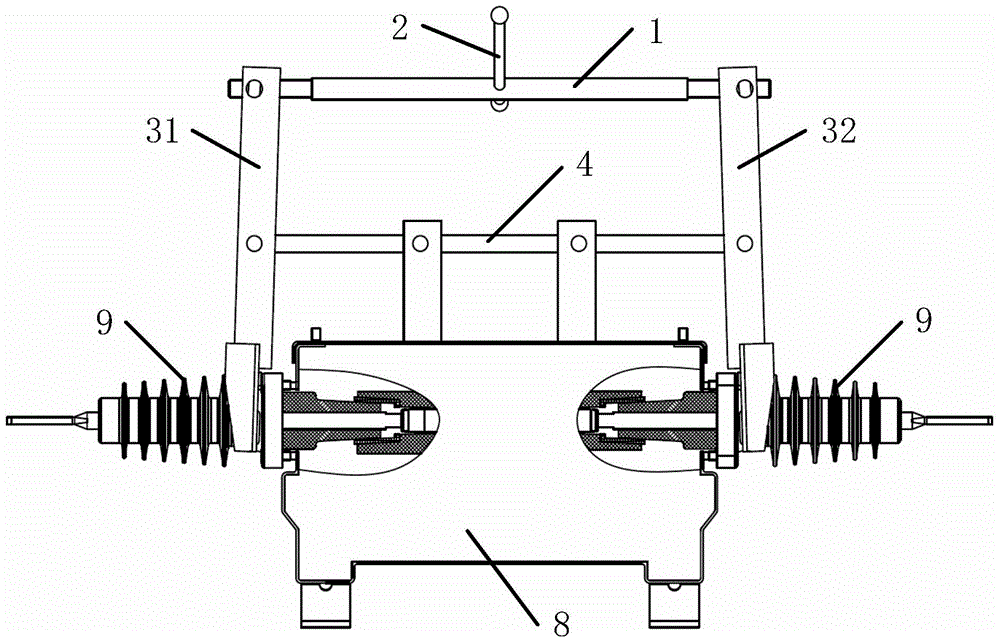

[0026] Such as Figure 1 to Figure 4 As shown, a tooling for installing the bushing of a vacuum circuit breaker is used to install the bushing 9 on the switch box 8, and its specific structure may include: a driving rod 1, an operating handle 2, and a left vertical pressure rod 31. The right vertical pressure bar 32, the support beam 4, the support column 5 and the support plate 7;

[0027] The operating handle 2 is fixed on the middle part of the driving rod 1; the two ends of the driving rod 1 are provided with external threads in opposite directions, and one end of the driving rod 1 is screwed to the top of the left vertical pressure rod 31, and the other end of the driving rod 1 It is threadedly connected with the top of the right side vertical pressure bar 32; one end of the support beam 4 is hinged with the middle part of the left side vertical pressure bar 31, and the other end of the support beam 4 is hinged with the middle part of the right side vertical pressure bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com