A magnetic separation device for iron ore powder

A magnetic separation device and technology for iron ore, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high requirements for water sources, inability to carry out water separation, and many losses of iron ore, etc. To achieve the effect of obvious sorting effect, protection of health and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

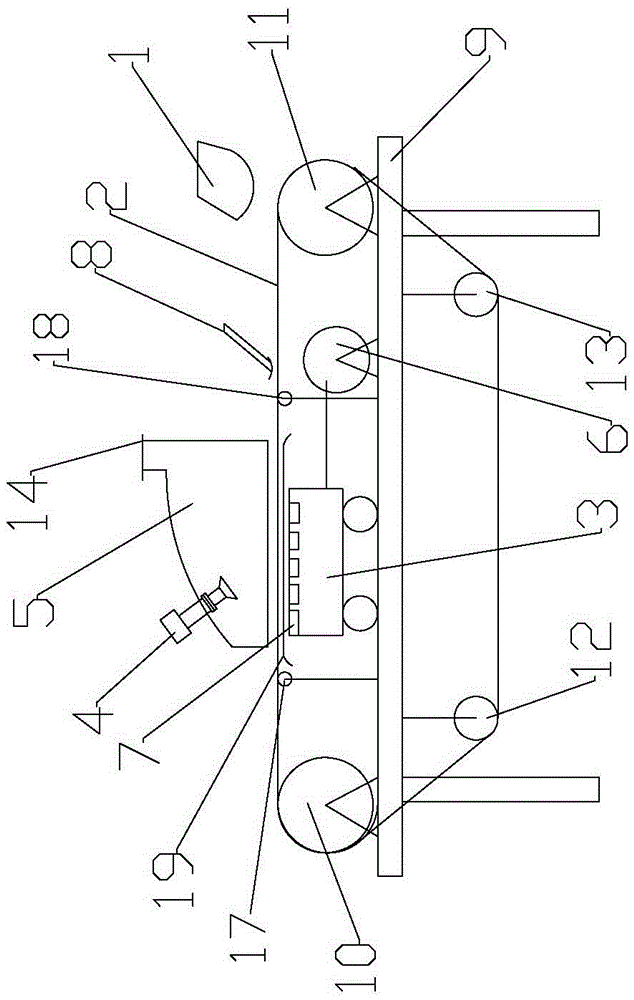

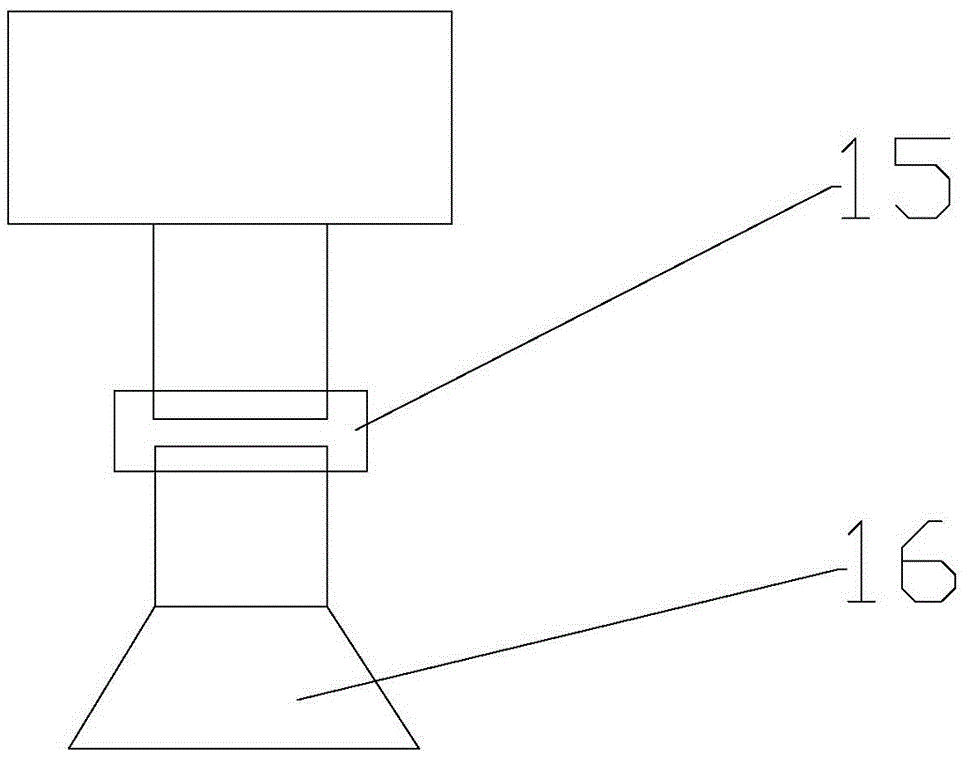

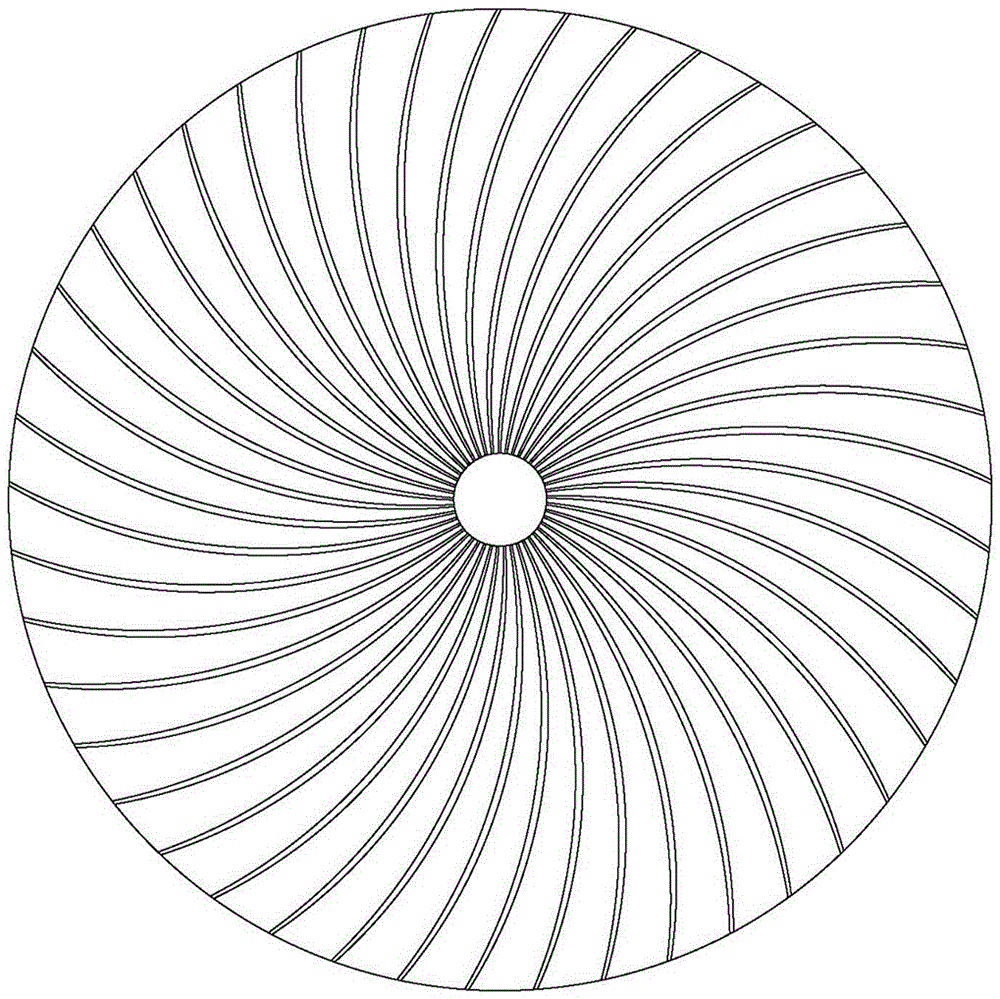

[0023] Such as figure 1 , 2 , Shown in 3, a kind of iron ore powder magnetic separation device comprises frame 9, and a belt pulley (10,11) is respectively installed on frame 9 upper side left and right ends, and frame lower side left and right ends are also installed with Two conveyor belt supporting wheels (12, 13), two belt supporting wheels are positioned between the two pulleys, a conveyor belt 2 is set on the two pulleys and the two belt supporting wheels, and a belt conveyor 2 is placed on the upper surface of the frame. Magnetic magnetic board car 3, magnetic board car is positioned at the below of conveyor belt, and magnetic board car comprises the dolly of belt wheel, and magnetic block 7 is installed on the upper surface of dolly, and stainless steel dividing plate 19 is installed on the magnetic block top, prevents conveying belt and magnetic The board car contacts, and a drive motor 6 with an eccentric wheel is also installed on the upper surface of the frame, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com