Panel, component for an airplane airfoil comprising the panel, and method for producing the panel

A wing and aircraft technology, applied in the field of plates, components for aircraft wings with the plates, and used to manufacture the plates, can solve the problem of difficulty in adding honeycomb filling parts or ribs, increasing the complexity of box-shaped structure assembly and Manufacturing costs and other issues to achieve the effect of increased stability and damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the panel according to the invention is described as a preferred embodiment for a panel for a trailing edge of a flap in an aircraft wing. It should be noted that the trailing edge of the flap is only exemplary, and the embodiments described below do not limit the present invention. The panel according to the invention can be used in aircraft wings with box-shaped components, for example main wings, flaps, ailerons, slats, empennages or components thereof, such as flap trailing edges.

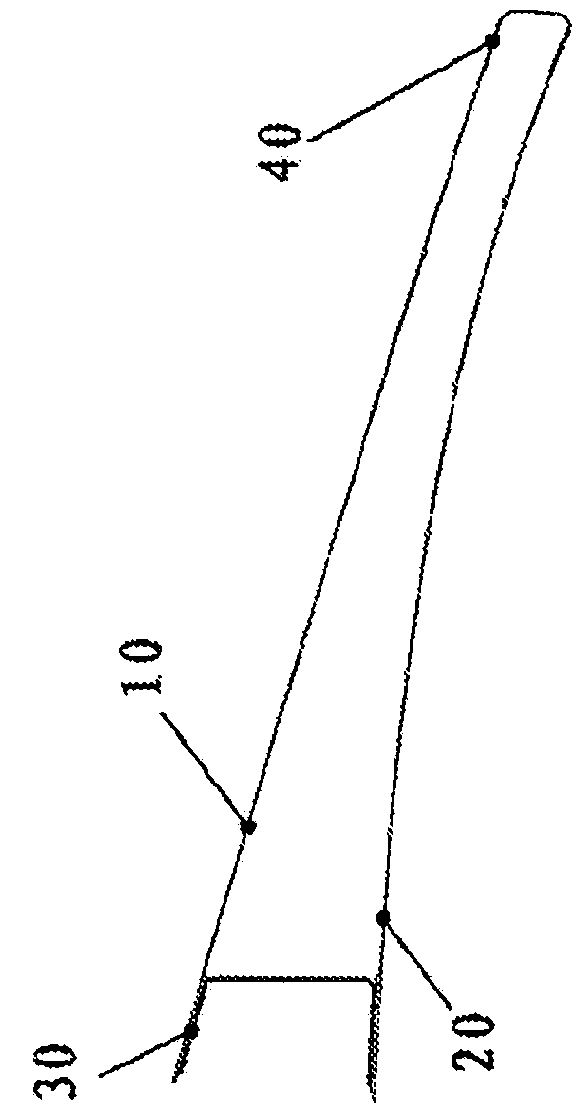

[0022] The flap includes a flap body and a trailing edge. refer to figure 1 , the trailing edge of the flap includes an upper skin 10 , a lower skin 20 , a front spar 30 and a closed end 40 . The upper skin 10 and the lower skin 20 respectively cover above and below the front spar 30 and the closed end 40, thereby forming a box-shaped structure.

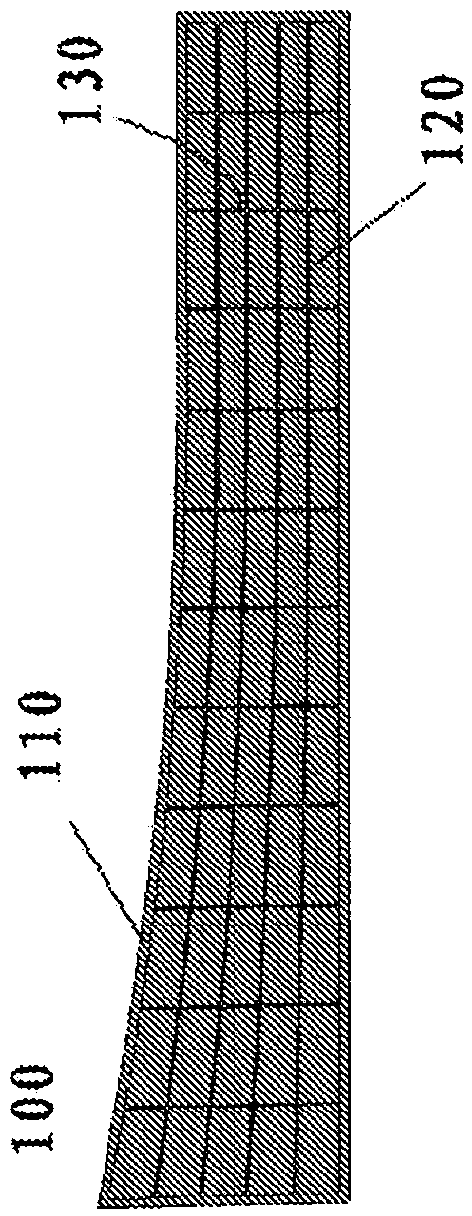

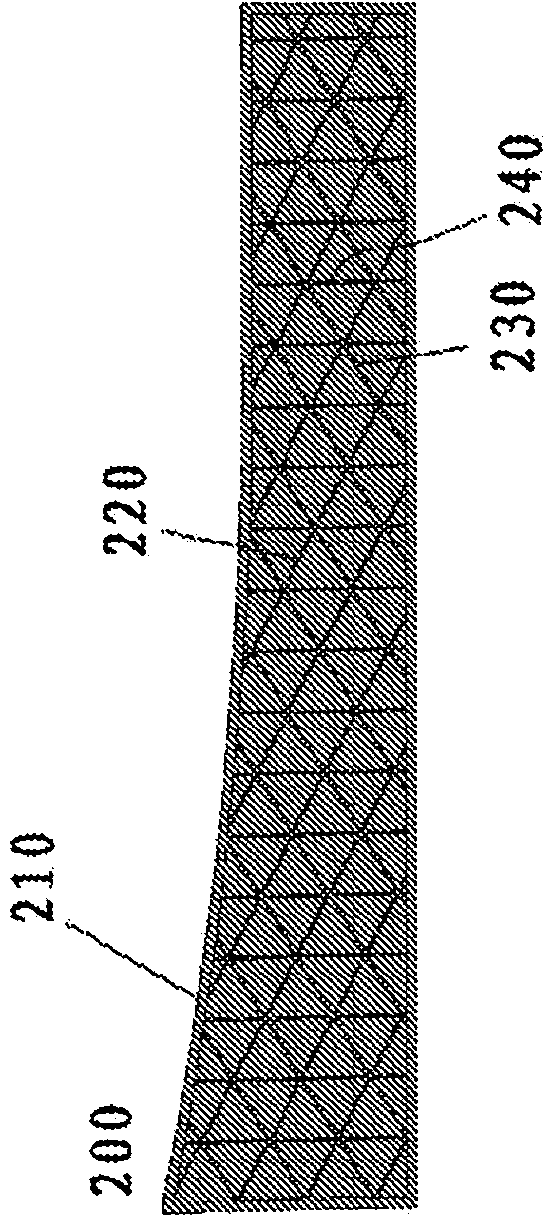

[0023] Figures 2 and 3 show a panel according to an embodiment of the invention for replacing the upper skin 10 or the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com