A Modification Method of PD Membrane Electrode Based on Formic Acid Electrooxidation

A modification method, membrane electrode technology, applied in battery electrodes, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. , Pt poisoning and other problems, to achieve the effect of improving catalytic activity and anti-poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

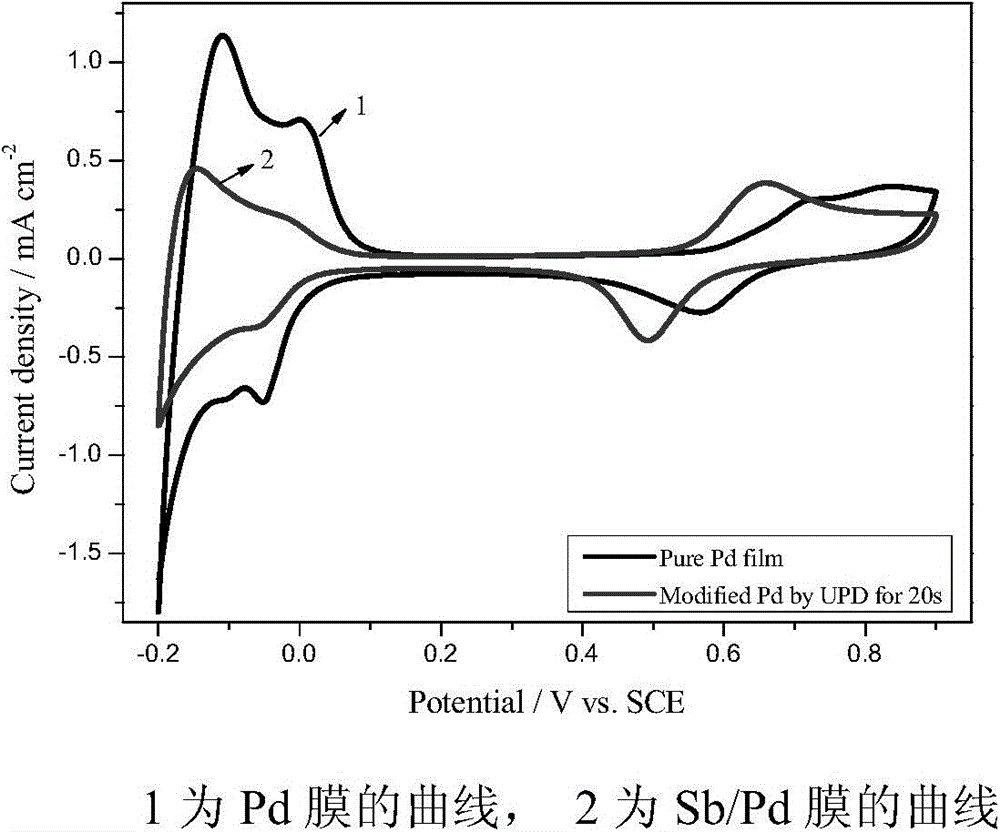

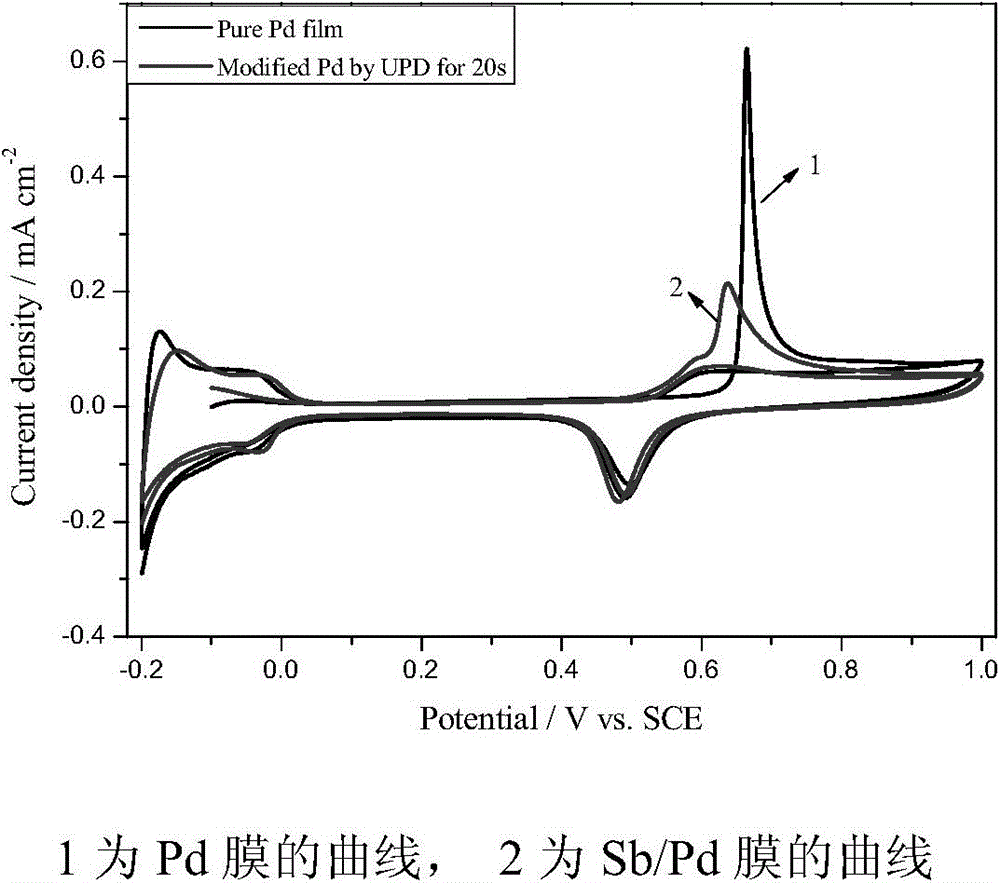

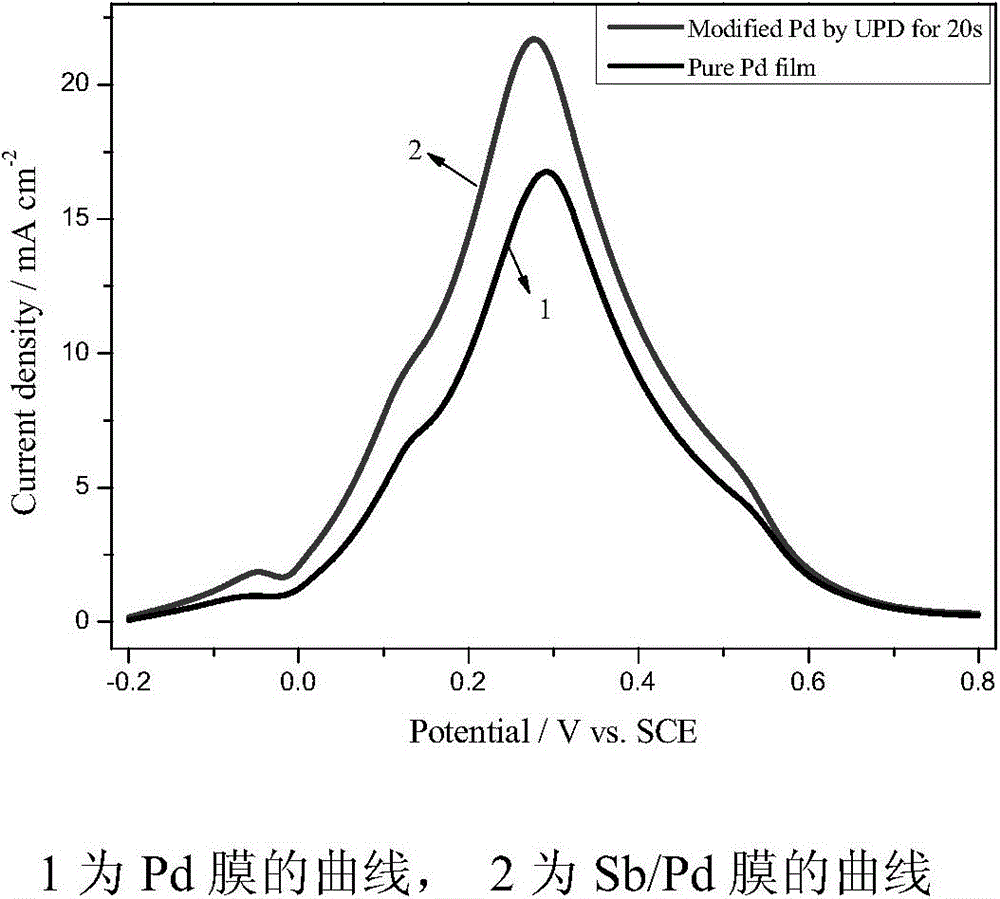

[0020] A method for modifying a Pd film electrode based on formic acid electrooxidation, using Sb to generate underpotential deposition on the Pd surface, depositing a single layer of Sb on the Pd substrate surface to improve the Pd surface structure, specifically adopting the following steps:

[0021] (1) Preparation of Pd film: the glassy carbon electrode was polished into a mirror surface on the suede, and then prepared in 0.1M HClO 4 Electrochemical cleaning (0~1.0V VS.SCE) is carried out in the process by cyclic voltammetry, and then palladium is deposited in the Pd plating solution (using cyclic voltammetry electrodeposition method, the plating solution is 5mM PdCl 2 +0.1M HClO 4 ).

[0022] (2) Deposit a single layer of Sb on the surface of the Pd film: deposit the Pd film with palladium in 0.1mM antimony potassium tartrate (APT)+0.5M H 2 SO 4 Centrally controlled potential deposition (0.2-0.3V vs. SCE) takes 10-30s to finish depositing a single layer of Sb on the su...

Embodiment 2

[0028] A method for modifying a Pd film electrode based on formic acid electrooxidation, using Sb to generate underpotential deposition on the Pd surface, depositing a single layer of Sb on the Pd substrate surface to improve the Pd surface structure, specifically adopting the following steps:

[0029] (1) Preparation of Pd film: the glassy carbon electrode was polished into a mirror surface on the suede, and then prepared in 0.1M HClO 4 In the process, cyclic voltammetry was used for electrochemical cleaning (0-1.0V VS.SCE), and a glassy carbon electrode was used as a working electrode, a platinum mesh was used as a counter electrode, and a saturated calomel electrode was used as a reference electrode to assemble it into a three-electrode system. , the electrolyte solution is 0.1M HClO 4 , the glassy carbon electrode is scanned by cyclic voltammetry, the scanning range: 0~1.0Vvs.SCE, the number of scanning segments: 50 segments, and the scanning speed: 0.1V / s. After cleaning,...

Embodiment 3

[0032] A method for modifying a Pd film electrode based on formic acid electrooxidation, using Sb to generate underpotential deposition on the Pd surface, depositing a single layer of Sb on the Pd substrate surface to improve the Pd surface structure, specifically adopting the following steps:

[0033] (1) Preparation of Pd film: the glassy carbon electrode was polished into a mirror surface on the suede, and then prepared in 0.1M HClO 4 In the process, cyclic voltammetry was used for electrochemical cleaning (0-1.0V VS.SCE), and a glassy carbon electrode was used as a working electrode, a platinum mesh was used as a counter electrode, and a saturated calomel electrode was used as a reference electrode to assemble it into a three-electrode system. , the electrolyte solution is 0.1M HClO 4 , using cyclic voltammetry to scan the glassy carbon electrode, the scanning range: 0 ~ 1.0V vs. SCE, the number of scanning segments: 50 segments, and the scanning speed: 0.1V / s. After clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com