An automatic label tearing device and method

A label and automatic technology, applied in the direction of instruments, computing, record carriers used by machines, etc., can solve the problems of non-conformity with modern production, occupation of labor, high work intensity, etc., to reduce manual actions, improve efficiency, and reduce work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

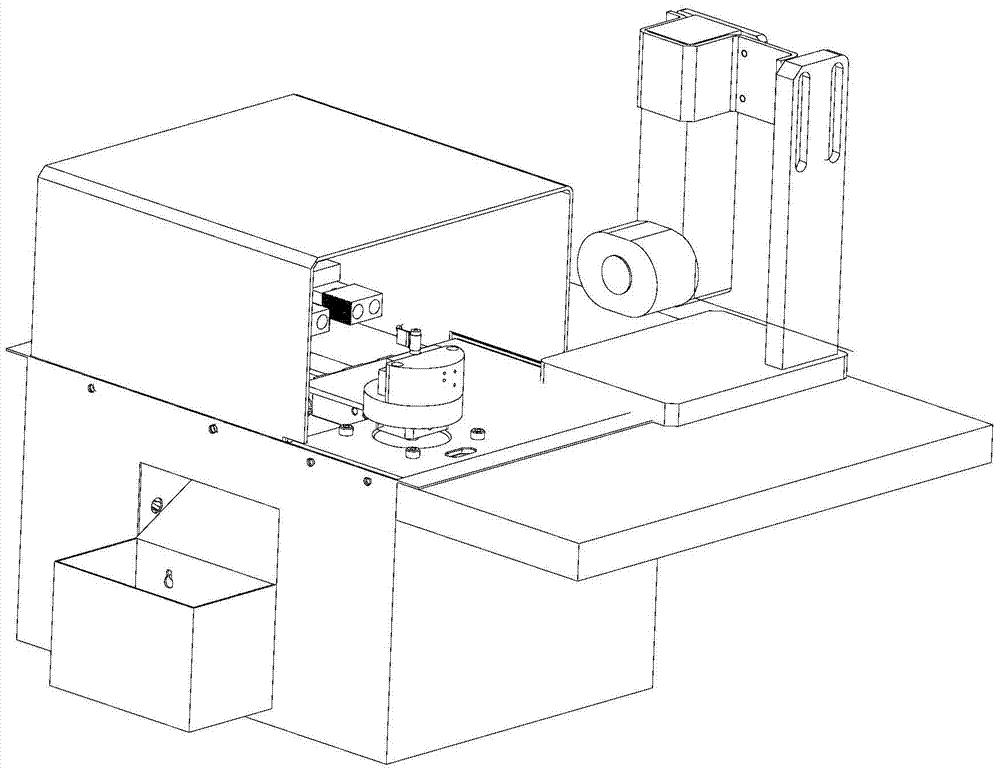

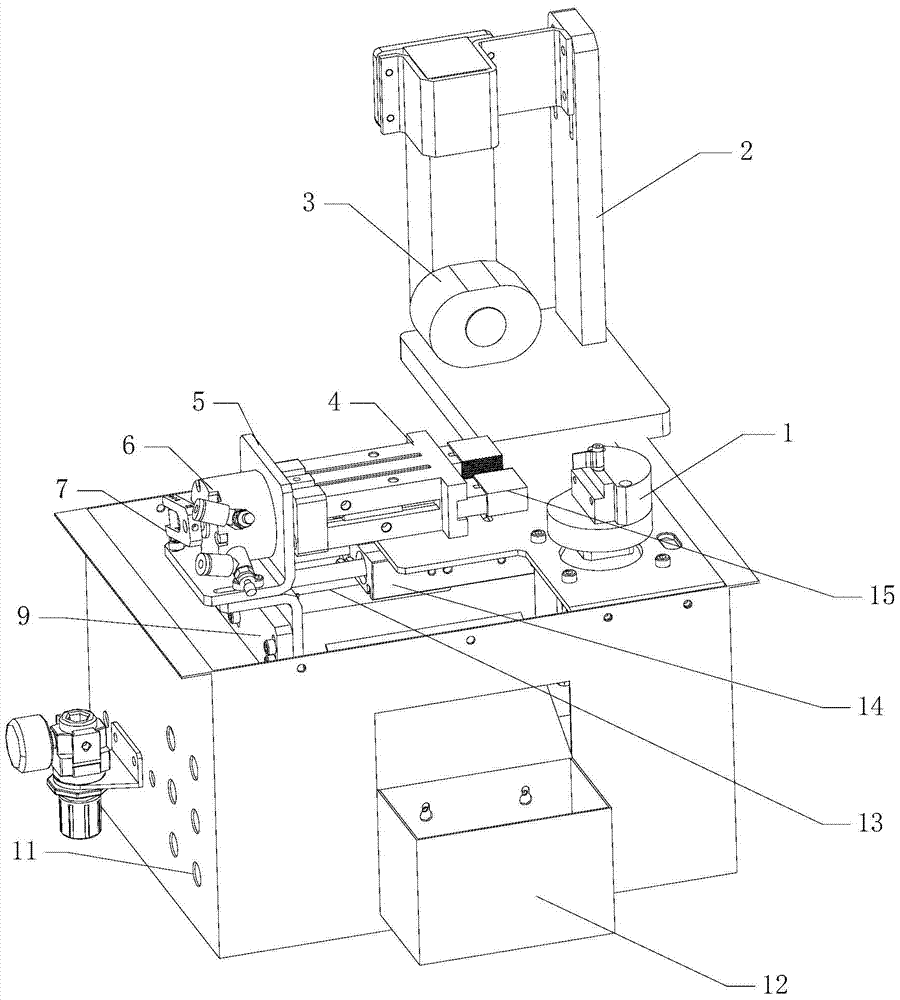

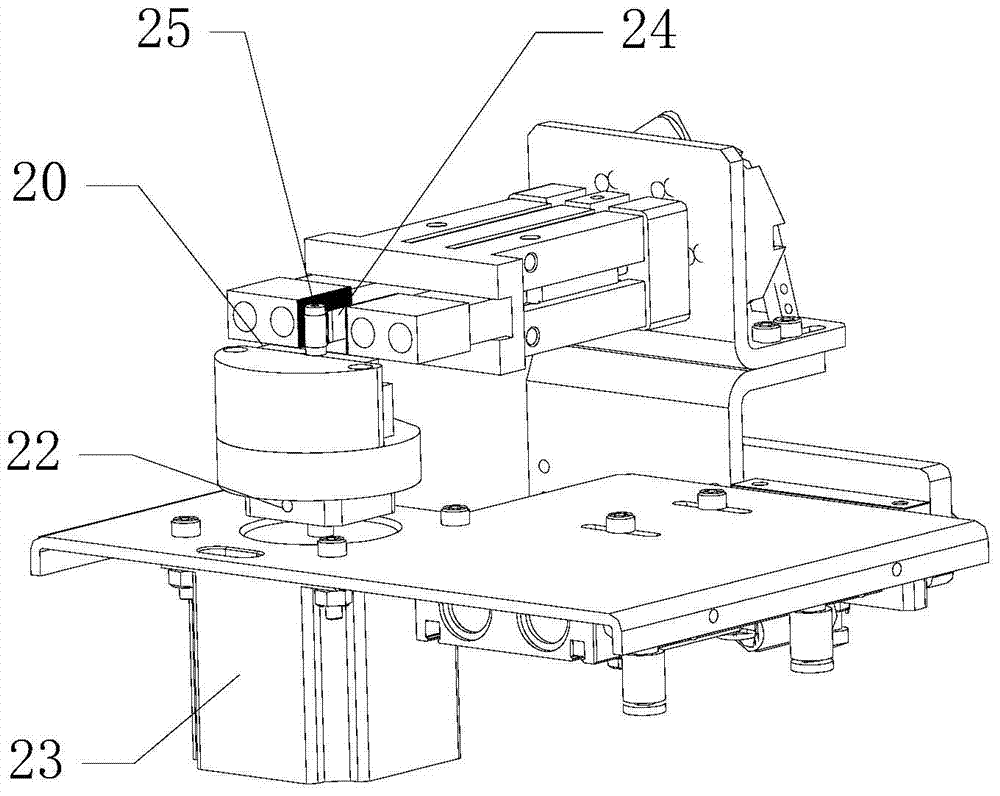

[0025] refer to figure 1 , figure 2 , image 3 , the present invention discloses an automatic label tearing device, which includes a rotating assembly 23, a test base 20, a push-pull device 14, and a jaw assembly composed of a jaw 4 and a swing assembly 6, etc. The automatic stripping of the label is realized through the linkage of the above-mentioned components, which can greatly improve the work efficiency and reduce the labor cost at the same time.

[0026] The test base 20 mainly provides a platform for product installation and fixing. For example, a jack matching the product plug can be set on the test base. When testing, the plug of the product is inserted and fixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com