Sealing ring structure for handset

A sealing ring and hand-held technology, which is applied in the direction of engine sealing, sealing casing, mechanical equipment, etc., can solve the problems of affecting production efficiency, growing a section, wasting human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the technical content of the present invention more clearly, the following embodiments are given for detailed description.

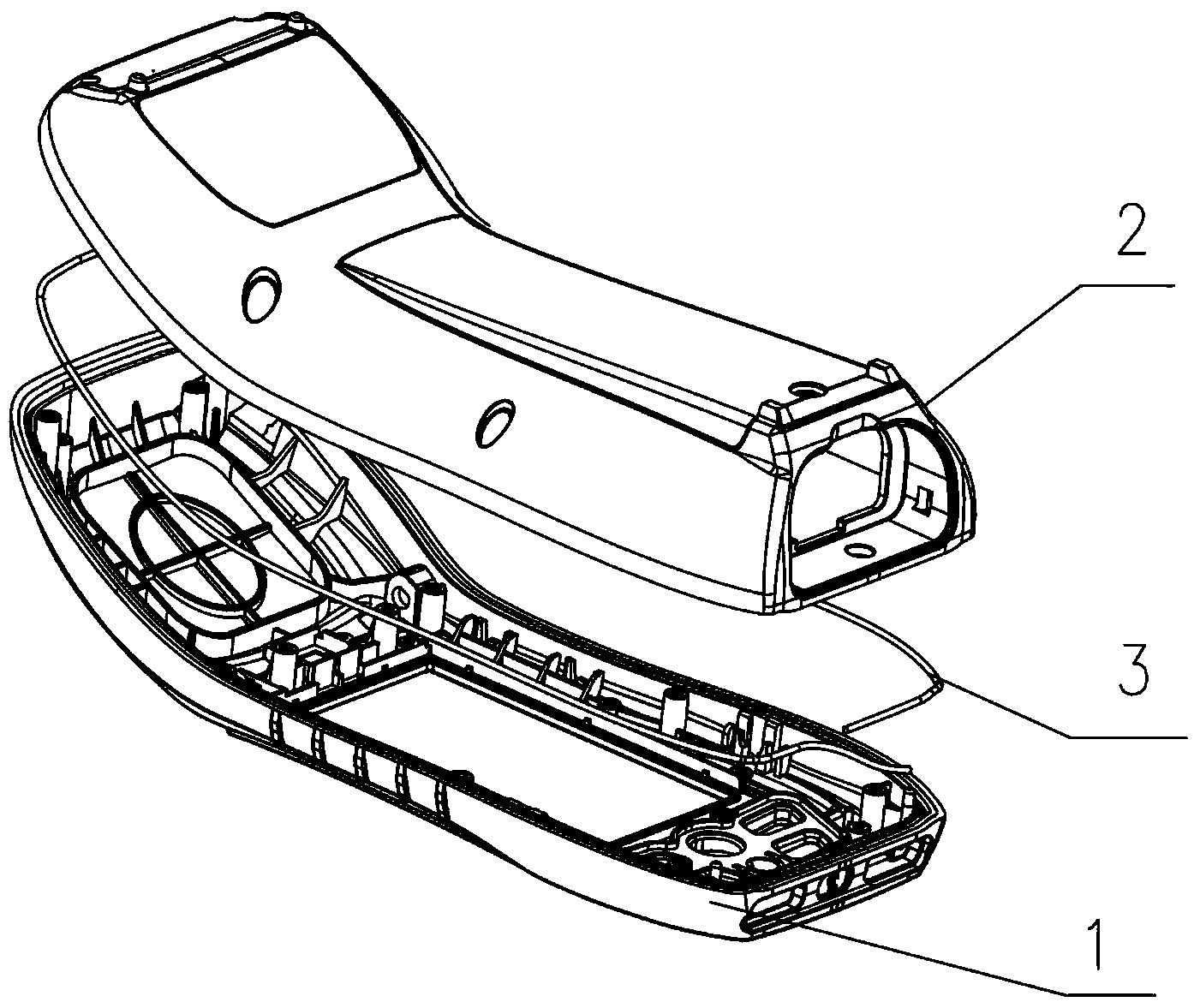

[0018] see figure 1 , The sealing ring structure of the handset is mainly characterized in that it includes a front shell 1 and a rear shell 2, a silicone strip 3 is arranged between the front shell 1 and the rear shell 2, and the internal space formed by the front shell 1 and the rear shell 2 passes through The silica gel strip 3 is separated from the outside world. The silica gel strip 3 is in the shape of a strip. One end and the other end of the silica gel strip 3 are fixedly connected by silica gel glue. The silica gel strip 3 forms a closed ring through the silica gel glue.

[0019] In the sealing ring structure of the handset, the edge of the front shell 1 is provided with an annular groove, and the silicone strip 3 is embedded in the groove. The depth of the annular groove is greater than the diameter of the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com