A spliced space truss partition floor

A space truss and floor slab technology, applied to floors, building components, buildings, etc., can solve the problems of large-span structural beams occupying space and high cost, and achieve the effects of facilitating water and electricity maintenance, reducing construction cost, and saving the use of height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

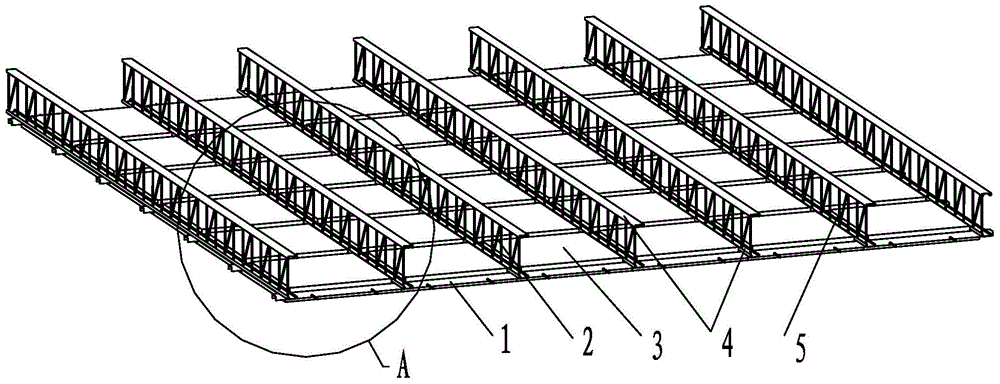

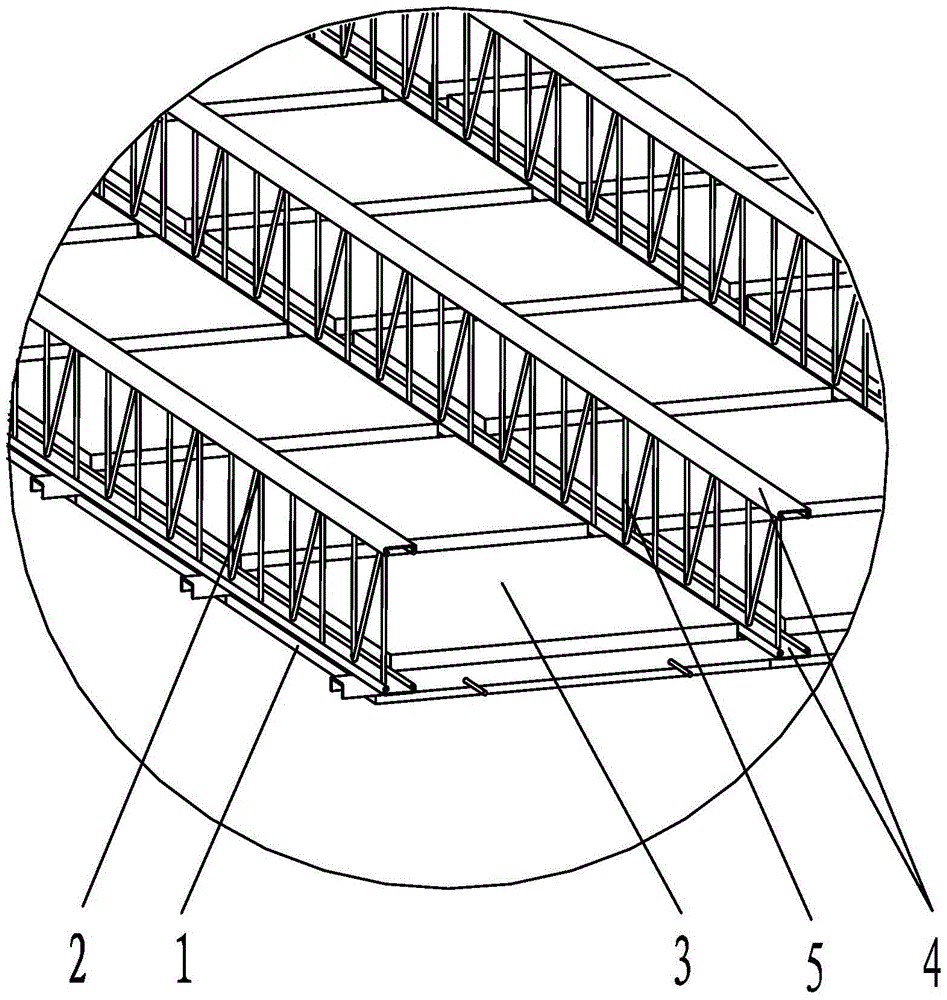

[0016] refer to figure 1 and figure 2 The present invention comprises a frame 1 welded by G-shaped steel, several plane trusses 2 are arranged in parallel on the frame 1, high-strength bolts are used between the frame 1 and the plane trusses 2, and upper floors are laid on the plane trusses 2. A bottom form 3 is arranged in the frame, and the bottom slab is formed by pouring between the bottom slab 3 and the bottom slab. The upper and lower water and strong and weak electricity are arranged in the interlayer between the bottom slab and the upper slab.

[0017] The plane truss 2 includes upper and lower trusses 4 made of G-shaped steel, channel steel or square steel, and several N-shaped unit steel bars 5 are welded and spliced between the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com