Sludge curing agent and sludge curing process employing sludge curing agent

A solidifying agent and sludge technology, applied in solid waste management, dewatering/drying/concentrating sludge treatment, sustainable waste treatment, etc. Good curing effect, stable mechanical properties and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

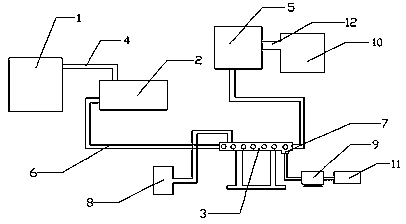

[0032] A kind of method utilizing above-mentioned sludge curing agent to carry out sludge solidification treatment, it comprises the following steps:

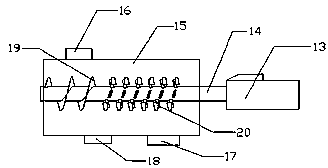

[0033] a. Sludge with a water content of 70%-90% is sent from the feed port to the pretreatment grid through the sludge pump for pretreatment to remove impurities and then sent to the sludge storage tank (1);

[0034] b. Send the sludge in the mud storage tank (1) to the concrete pump (2) through the first conveying device (4), and then to the screw mixer (3) through the pipeline (6), and at the same time, the powder The curing agent is added to the screw mixer (3) through the curing agent addition inlet (18) through the powder supply machine and the constant pressure and constant flow pump together with the curing agent described in the present invention;

[0035] c. Send the solidified mud to the landfill through the second delivery device (9).

[0036] The silt in this example is common silty marine silt from Liaodong, Hebe...

Embodiment 2

[0039] A kind of method utilizing above-mentioned sludge curing agent to carry out sludge solidification treatment, it comprises the following steps:

[0040] a. Sludge with a water content of 70%-90% is sent from the feed port to the pretreatment grid through the sludge pump for pretreatment to remove impurities and then sent to the sludge storage tank (1);

[0041] b. Send the sludge in the mud storage tank (1) to the concrete pump (2) through the first conveying device (4), and then to the screw mixer (3) through the pipeline (6), and at the same time, the powder The curing agent is added to the screw mixer (3) through the curing agent addition inlet (18) through the powder supply machine and the constant pressure and constant flow pump together with the curing agent described in the present invention;

[0042] c. Send the solidified mud to the landfill through the second delivery device (9).

[0043] The silt in this example is common silty marine silt from Liaodong, Hebe...

Embodiment 3

[0046] A kind of method utilizing above-mentioned sludge curing agent to carry out sludge solidification treatment, it comprises the following steps:

[0047] a. Sludge with a water content of 70%-90% is sent from the feed port to the pretreatment grid through the sludge pump for pretreatment to remove impurities and then sent to the sludge storage tank (1);

[0048] b. Send the sludge in the mud storage tank (1) to the concrete pump (2) through the first conveying device (4), and then to the screw mixer (3) through the pipeline (6), and at the same time, the powder The curing agent is added to the screw mixer (3) through the curing agent addition inlet (18) through the powder supply machine and the constant pressure and constant flow pump together with the curing agent described in the present invention;

[0049] c. Send the solidified mud to the landfill through the second delivery device (9).

[0050] The silt in this example is common silty marine silt from Liaodong, Hebe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com