Damping type over discharge buffering device for mine hoisting system

A technology of lifting system and buffer device, which is used in elevators, transportation and packaging, etc., to achieve the effect of short construction period, reduction of safety transformation problems, and short production shutdown period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

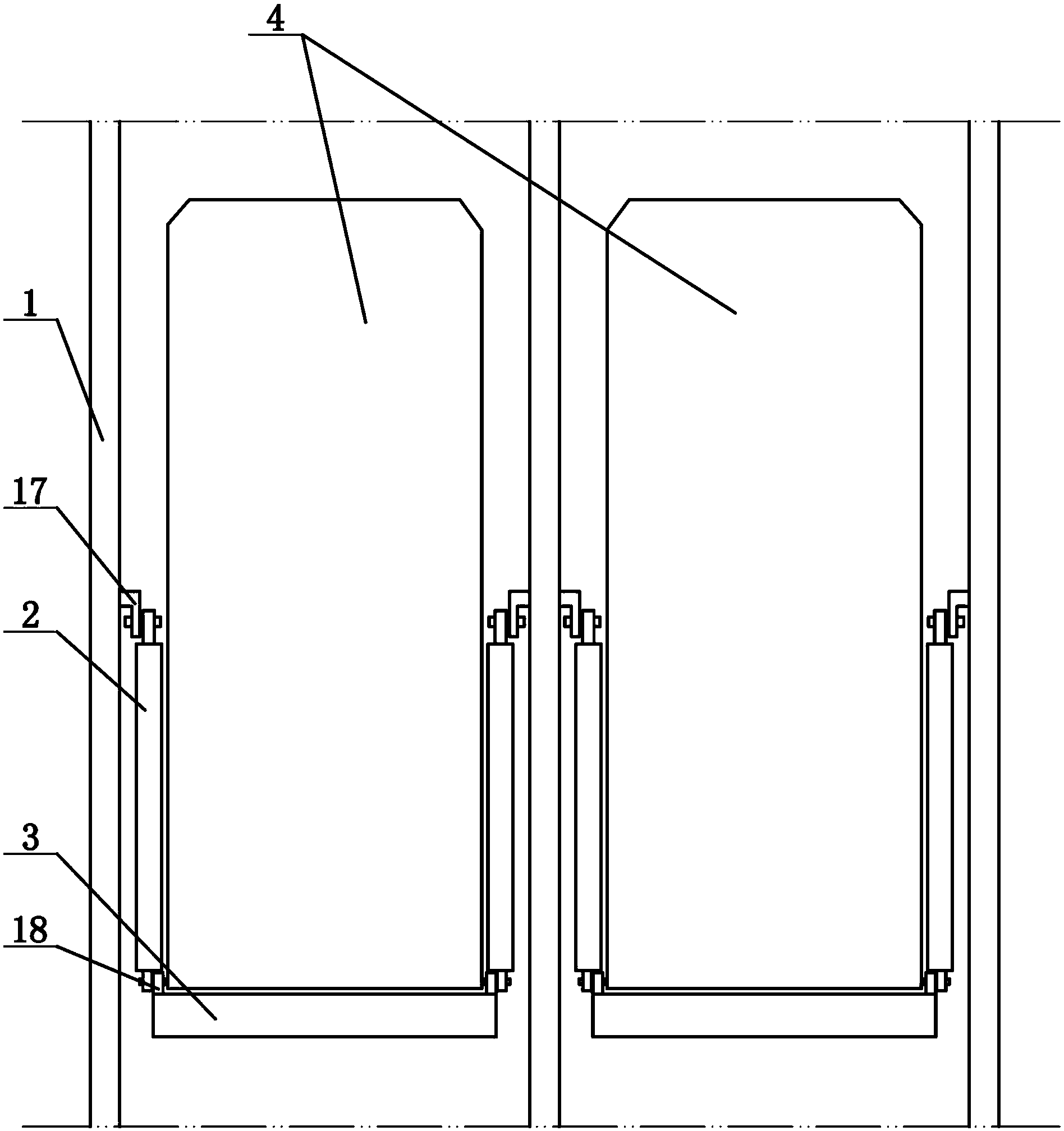

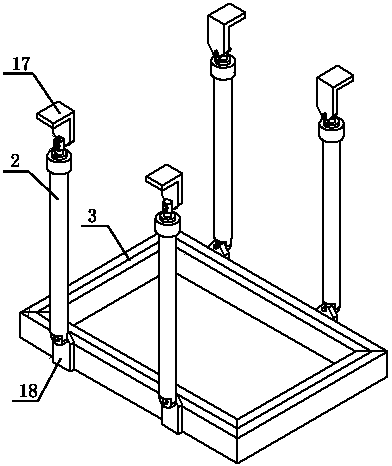

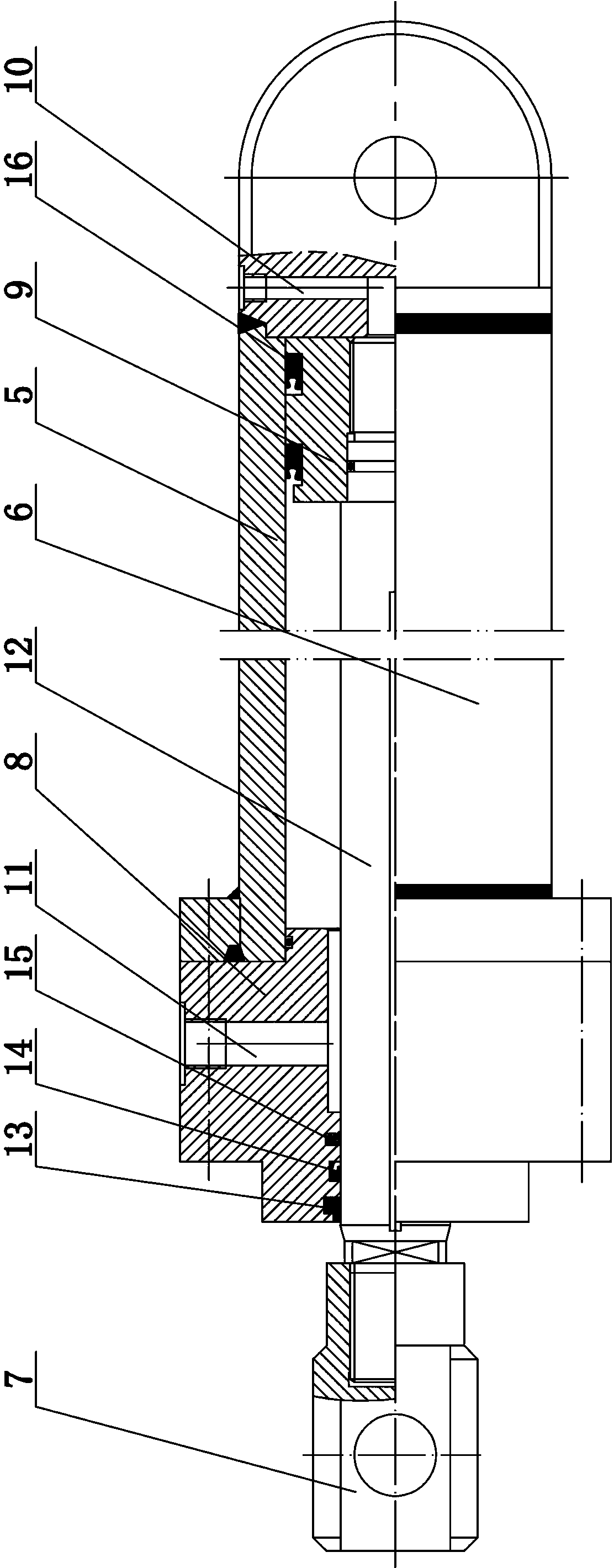

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a damping type over-discharging buffer device for a mine hoisting system includes a steel truss 1, a damping buffer 2 and a buffer bracket 3. The steel truss 1 is arranged on the bottom shaft wall of the mine, and the upper end of the damping buffer 2 The upper hanging plate 17 is connected to the steel truss 1, the lower end of the damping buffer 2 is connected to the buffer bracket 3 through the lower hanging plate 18, and the cage 4 of the mine hoisting system falls on the buffer bracket 3 when it falls. Hanging plate 17 is an "L" type hanging plate. The damping buffer 2 includes a hydraulic cylinder 5, a piston rod 6, a joint 7, a front end cover 8 and a piston 9. The hydraulic cylinder 5 is a cylinder structure with one end open. , the open end is fixed with a front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com